Parallel IGBT driving method of power electronic equipment

A technology of power electronics and driving method, which is applied in the field of parallel IGBT driving, can solve the problems of large transmission time jitter and inapplicability, and achieves the improvement of turn-on and turn-off capability, simple solution, and suppression of static and dynamic uneven currents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

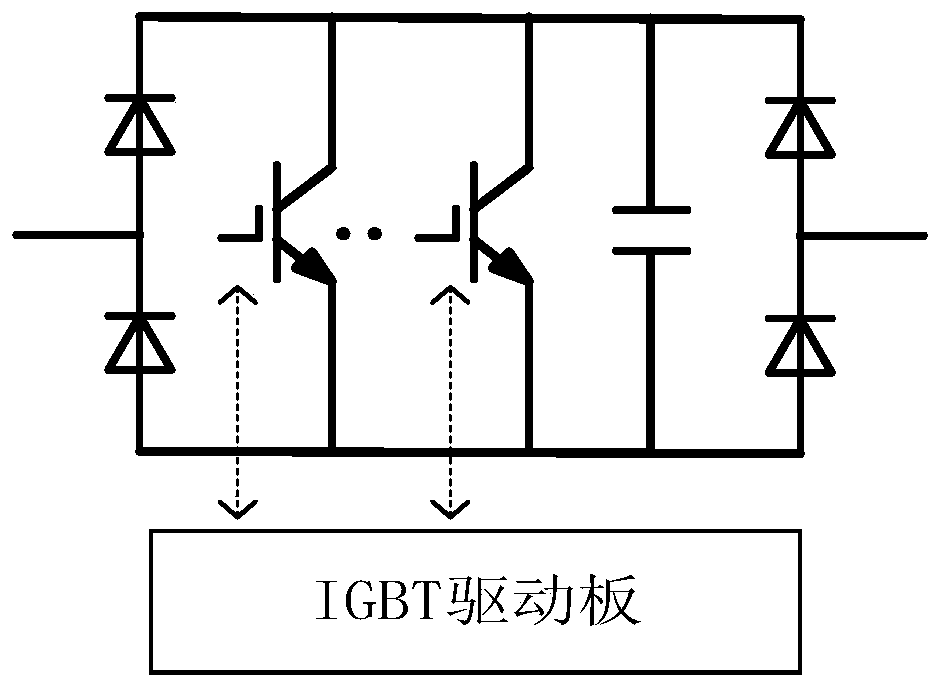

[0024] As the current level continues to increase, power electronic equipment requires multiple IGBTs to be directly connected in parallel to increase the ability of the device to turn on or turn off the current. figure 2 It is a valve group topology aimed at by a parallel IGBT driving method of power electronic equipment in the present invention. The valve group in the figure includes at least two parallel IGBTs, and the number of parallel IGBTs is closely related to the device current parameters. In order to better control parallel IGBT devices, it is necessary to configure a special driver board as the control interface of the IGBT.

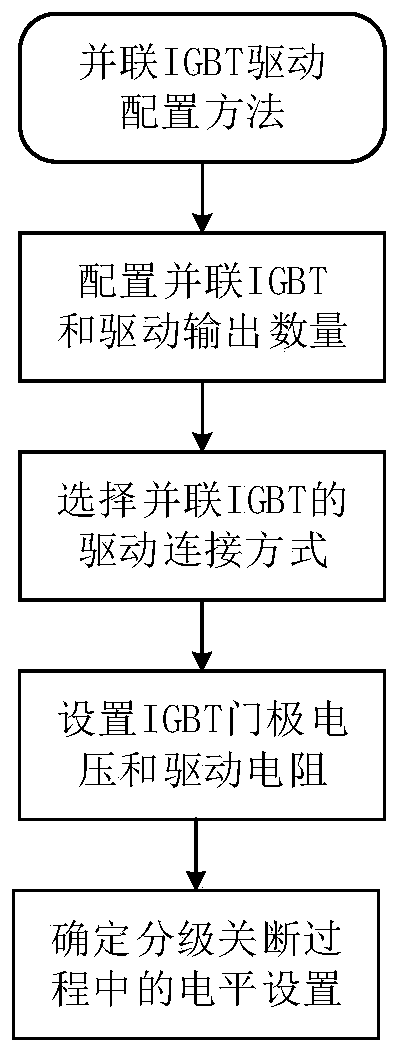

[0025] figure 1 Shown is an IGBT driving method for the above-mentioned power electronic device topology, including the following steps:

[0026] Step 1: Configure the number of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com