Intelligent workpiece chuck device for manual chuck type numerical control lathe

A technology of CNC lathes and manual chucks, which is applied to chucks, accessories of toolholders, turning equipment, etc., can solve problems such as difficulty in grasping the torque of fixed workpieces, inability to achieve intelligence, and inability to directly apply electric cutterheads, etc. Achieve the effect of non-contact control, simple and compact structure, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

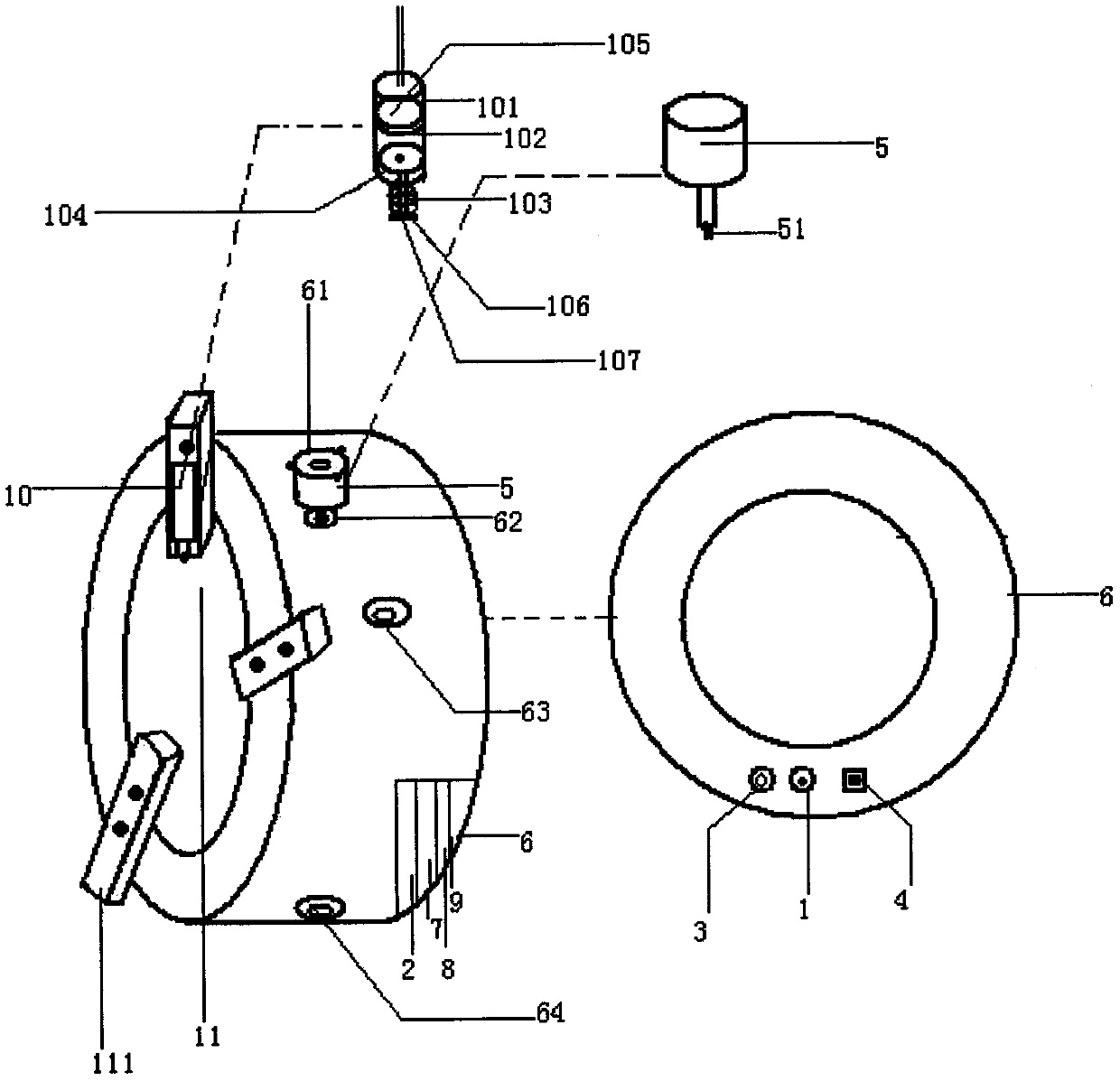

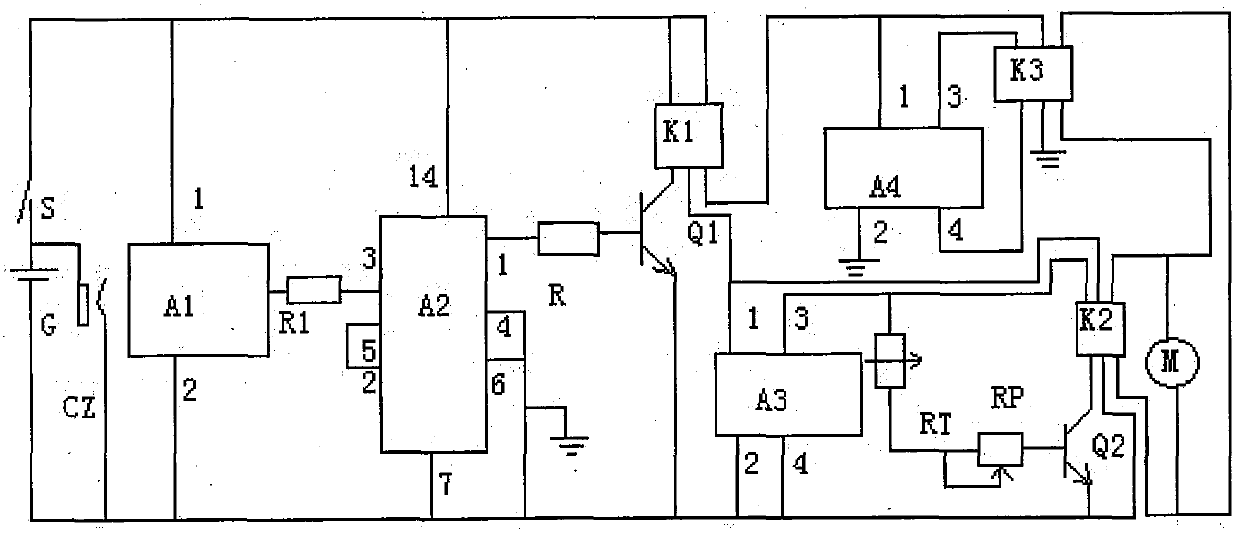

[0016] figure 1 As shown in , the intelligent workpiece chuck device used by the manual chuck type CNC lathe includes a photoelectric switch 1, a battery 2, a charging socket 3, a power switch 4, a motor deceleration mechanism 5, an annular metal casing 6, and a trigger circuit 7 , the first control circuit 8, the second control circuit 9, the trigger mechanism 10; the metal casing 6 has two layers inside and outside, a lower opening 62 is arranged in the middle of the inner layer of the metal casing 6, and the outer layer of the metal casing 6 There is an upper opening 61 in the middle, the upper opening 61 and the lower opening 62 are aligned, and the side end of the upper opening 61 has a plurality of fixing holes. A plurality of screw nuts are fixedly installed between the inner and outer layers of the metal casing 6 respectively; the inner diameter of the inner layer of the metal casing 6 is slightly larger than the outer diameter of the manual chuck 11, and the middle ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com