Mobile assembly type drop hammer impact test device and mounting method

A technology of drop weight impact test and installation method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the bottom plate cannot be disassembled, inconvenient to move, difficult to operate the pulley, etc., and achieves the reduction of disassembly procedures, simple structure, and easy access Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

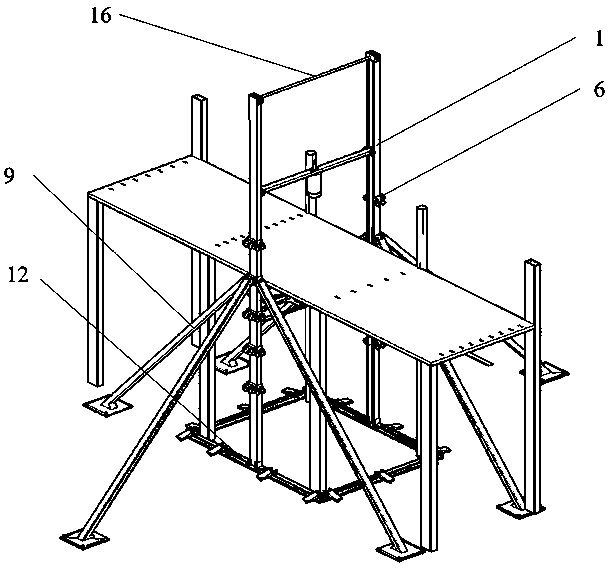

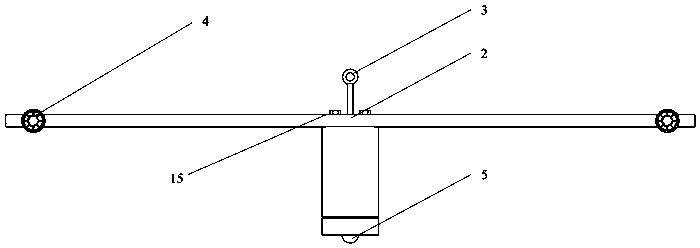

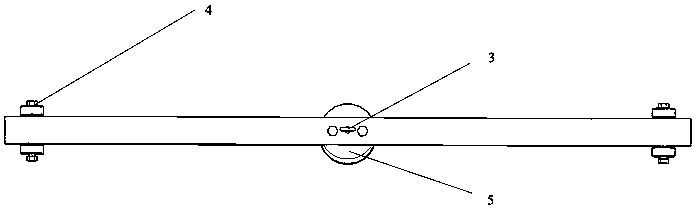

[0043] Such as Figure 1 to Figure 9 As shown, a mobile assembly type drop weight impact test device and installation method include a test bench, a drop weight 1 and a force sensor 5; the test bench is composed of a channel steel base 12, a guide rail 6, a support rod 9 and a steel beam 2 .

[0044] Such as Figure 4 to Figure 5 As shown, the channel steel base 12 is made up of four channel steels, the bottom of the channel steel base 12 is provided with a trapezoidal backing plate, and the channel steel is provided with a universal wheel clamp 13 at a distance. The guide rail 6 is vertically arranged on the channel steel base 12, and the guide rail 6 is provided with a convex connecting plate 8 at a certain distance, and the convex connecting plate 8 is provided with a rectangular groove.

[0045] Such as Figure 2 to Figure 3 As shown, the long bolt 3 with a ring is fixed in the pre-drilled screw hole of the steel beam 2, and then the steel beam 2 is placed on the top su...

Embodiment 2

[0055] An installation method of a mobile assembly type drop weight impact test device, comprising using a mobile assembly type drop weight impact test device as in embodiment 1, such as Figure 1 to Figure 14 As shown, its installation method includes the following steps:

[0056] Step 1: Weld two steel plates on the channel steel base 12 . When installing the universal wheel module 4, pass a long screw through the outer ends of the two steel plates, string together with the universal wheel module 14, and then tighten the nut. Thread the second long screw through the inside end of the steel plate with a rectangular support plate welded in the middle of the screw. When the universal wheel module 14 rotates in the vertical plane, the rectangular support plate clamps the groove of the universal wheel module 14 to transmit the vertical support force of the ground. The guide rail 6 is respectively provided with a convex connecting plate 8 on each of the three surfaces at a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com