Decision-making method for dynamically optimizing wellbore heating parameters

A technology of dynamic optimization and decision-making method, applied in the direction of design optimization/simulation, data processing application, electrical digital data processing, etc., can solve the problem that the heating critical condition is not targeted, the heating power and water injection temperature cannot be obtained, and the crude oil viscosity difference is relatively large. major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

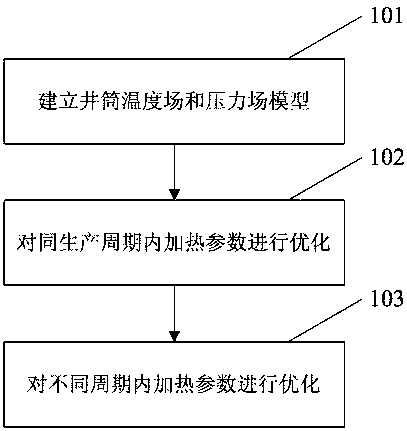

[0097] Such as figure 1 as shown, figure 1 It is a flow chart of the decision-making method for dynamically optimizing wellbore heating parameters of the present invention. The method mainly includes:

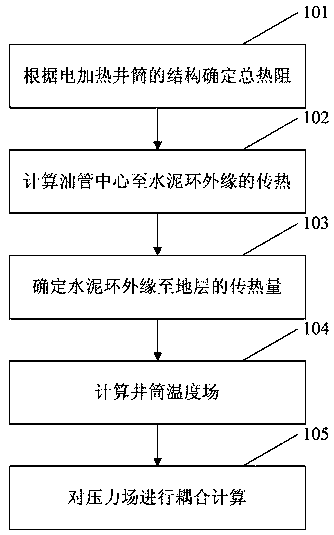

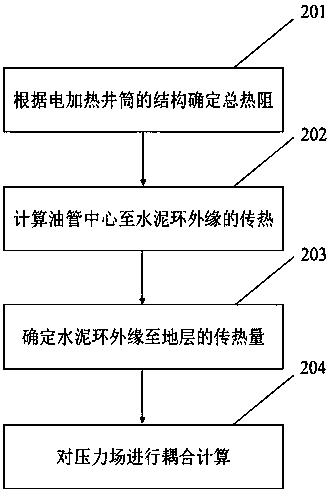

[0098] Step 1, establish the wellbore temperature field and pressure field model; the establishment of the wellbore temperature field model can be divided into two types according to different heating processes, such as figure 2 As shown, the electric heating process modeling process is as follows:

[0099] Step S101: Determine the total thermal resistance R according to the structure of the electric heating wellbore. The total thermal resistance consists of 5 parts, namely: the convective heat transfer thermal resistance R of the liquid film layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com