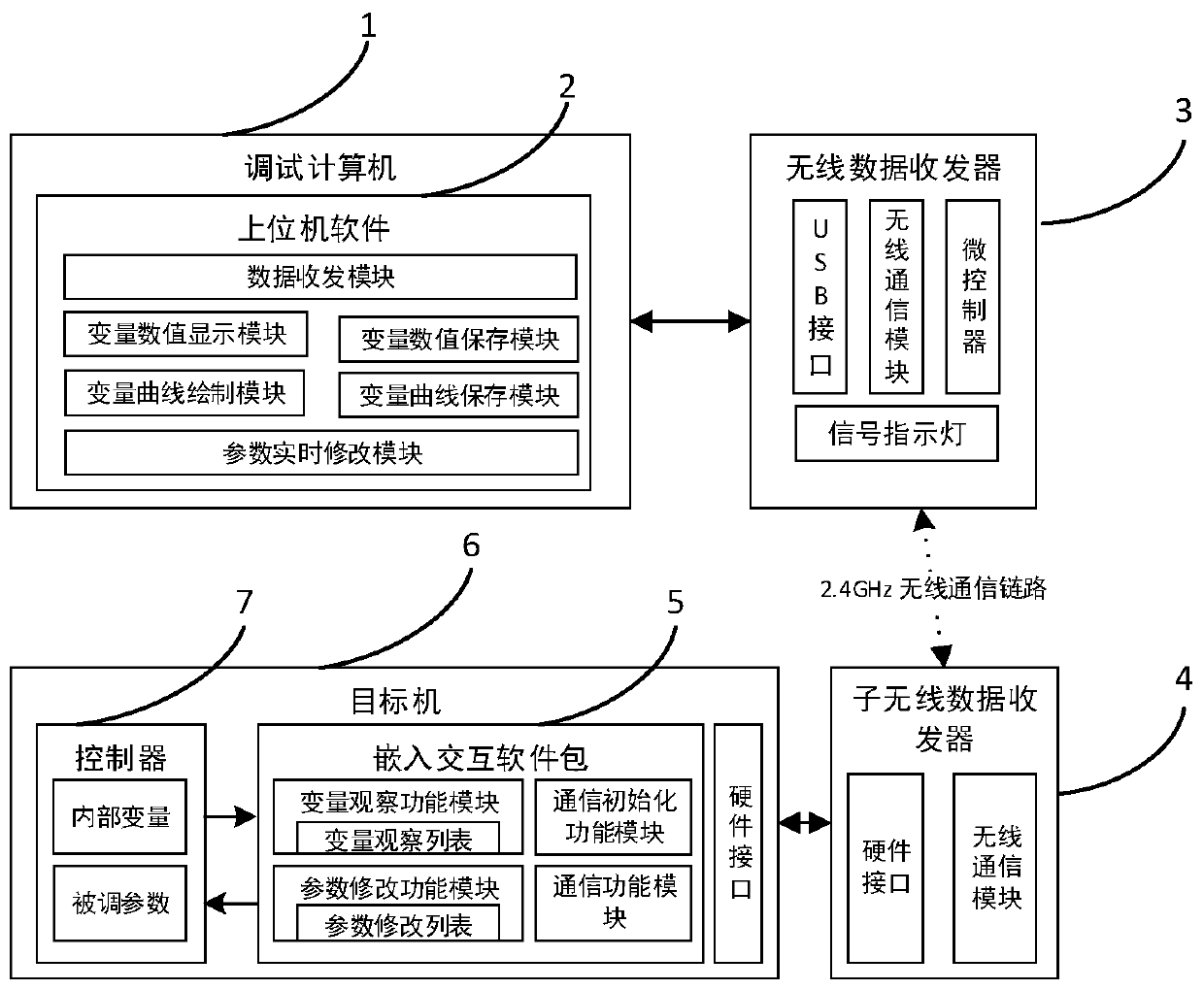

System and method for wireless analysis and debugging of controller parameters

A technology for debugging systems and controllers, applied in software testing/debugging, instruments, electrical digital data processing, etc., can solve the problems of redundant debugging cables, interference of equipment working environment, and low parameter quality, saving time and labor costs , The effect of shortening parameter adjustment time and improving parameter quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

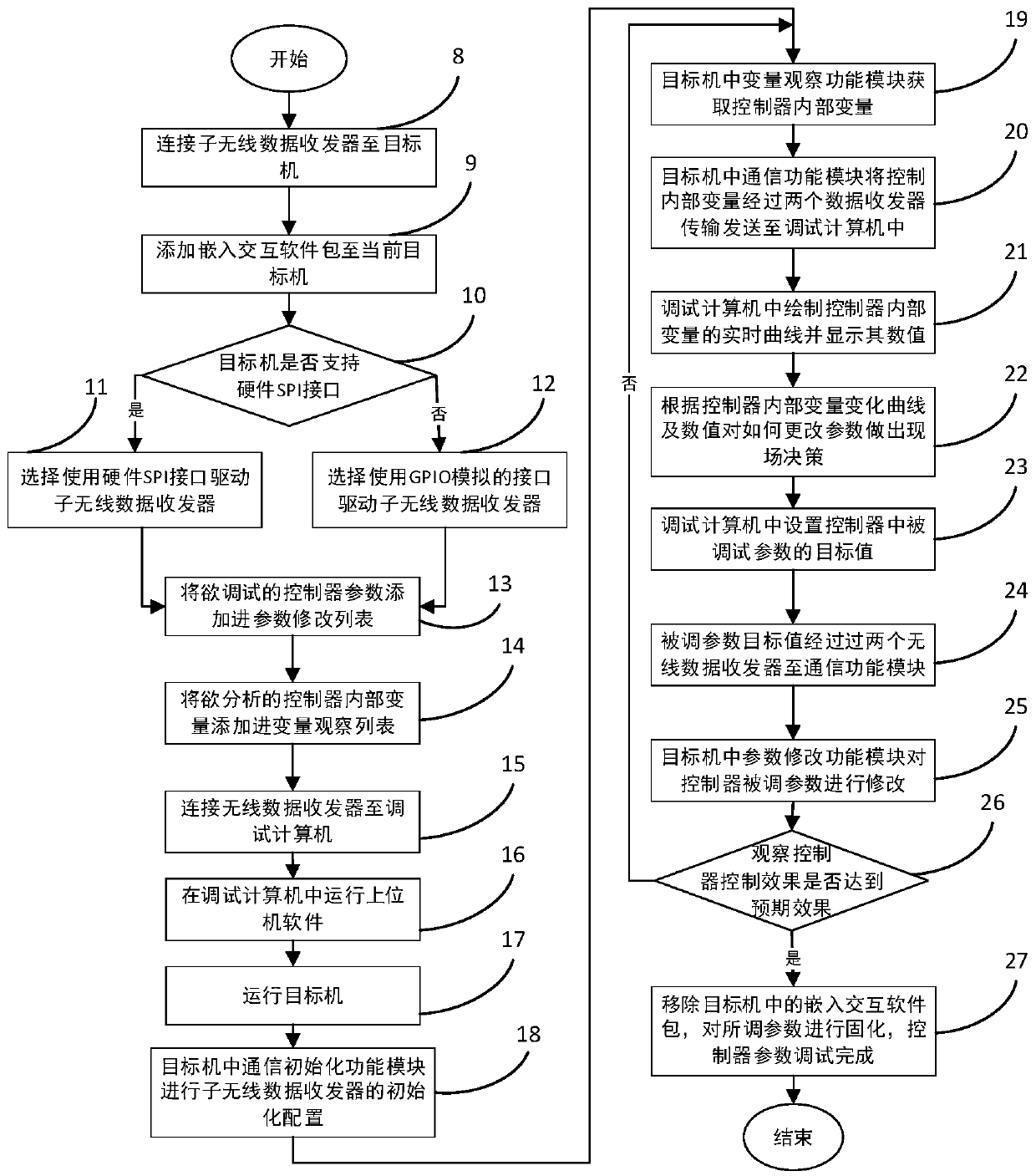

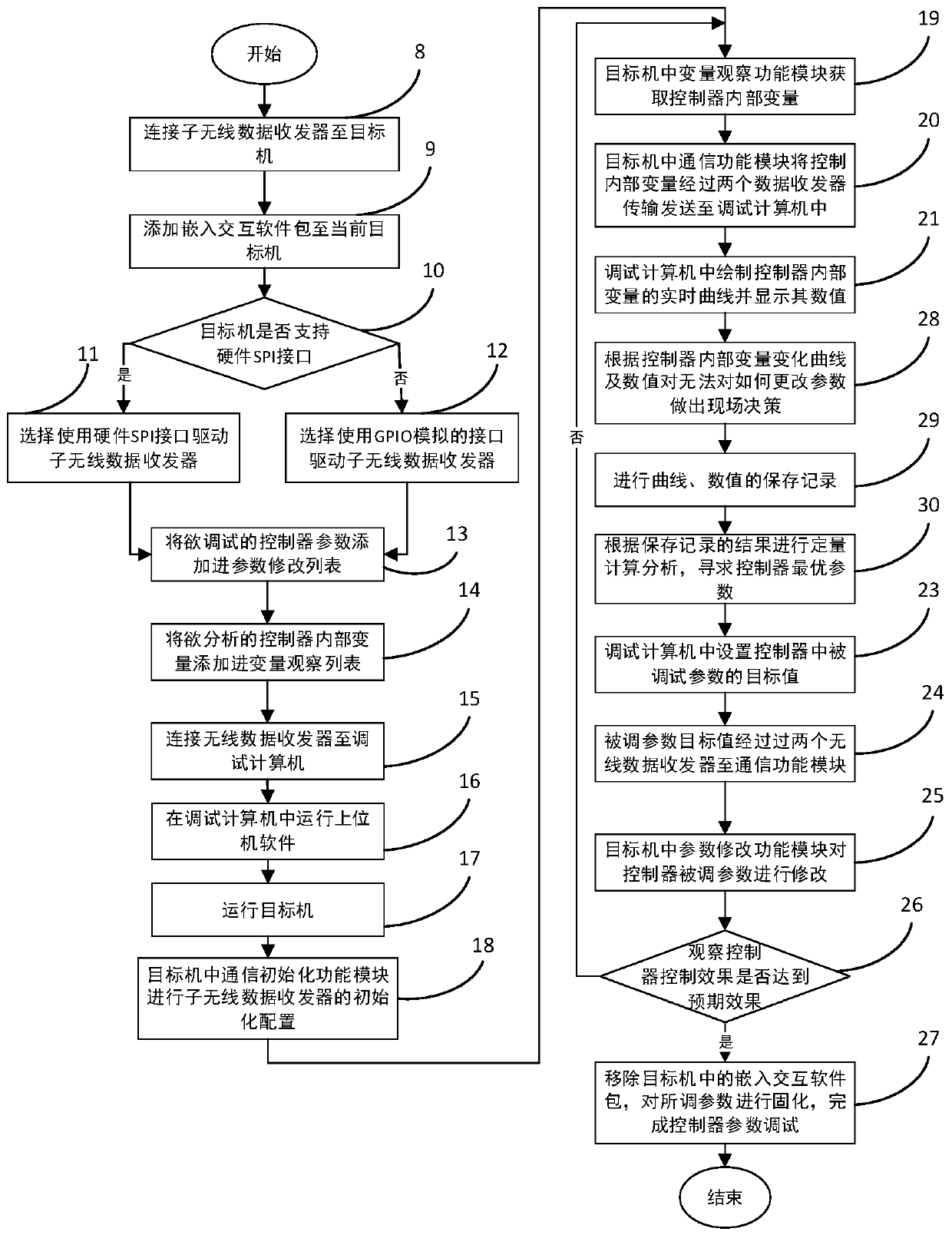

[0052] In the first embodiment of the present invention, a method for wireless analysis and debugging of controller parameters, such as figure 2 shown, including the following specific steps:

[0053] The first step: if figure 2 As shown in 8, connect the sub-wireless data transceiver to the target machine through the hardware interface.

[0054] The second step: if figure 2 As shown in 9, 10, 11 and 12, add the embedded interactive software package to the current target machine, and select the sub-wireless data transceiver driving method according to the actual situation; when the target machine supports the hardware SPI interface, choose to use the hardware SPI interface to drive the sub-wireless data Transceiver: When the target machine hardware does not support the hardware SPI interface, choose to use the GPIO simulated interface to drive the sub-wireless data transceiver.

[0055] Step 3: If figure 2 As shown in 13 and 14, the controller parameters to be debugged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com