Food forming method provided with split-type forming mold

A forming mold and food forming technology, which is applied in the field of food processing, can solve the problems of bloated structure, large space occupation, and affecting the normal operation of the dumpling structure, and achieve the effects of saving space and cost, saving space, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

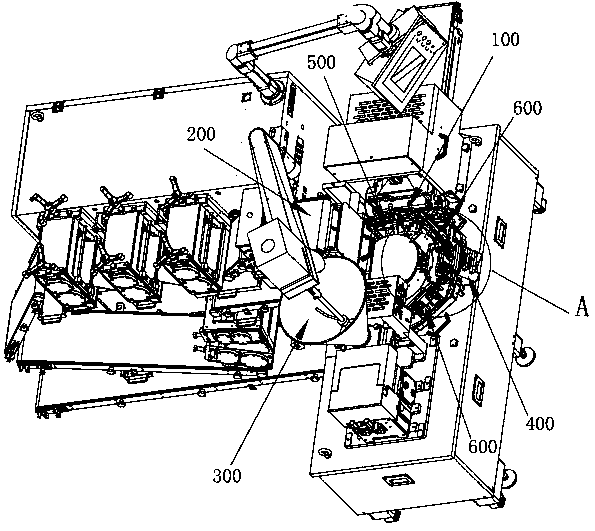

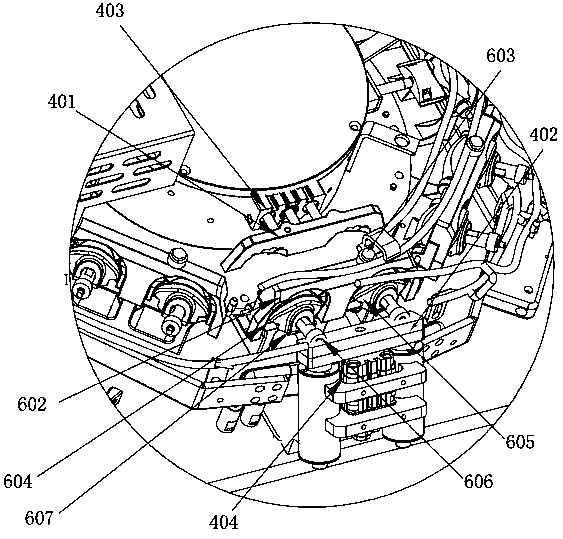

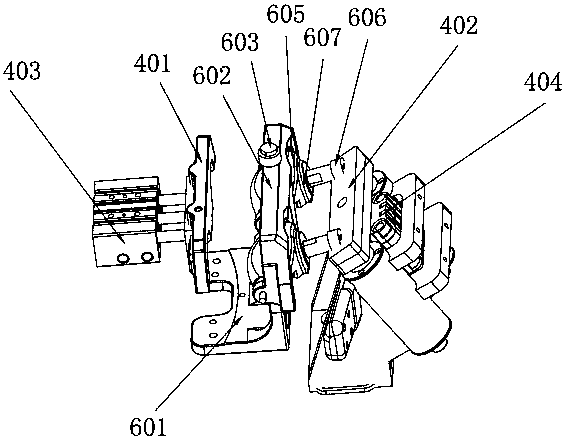

[0035] A food forming method provided with a split forming mold, comprising the following steps: After the dough is processed by a noodle supply device 200, it falls on a forming mold 600 located at a noodle supplying station, and the forming mold 600 moves to a filling station, injecting The stuffing device 300 injects the stuffing on the dough of the forming mold 600, the forming mold 600 continues to move to the forming station, the first forming plate 401 on the forming device 400 and the second forming plate 602 on the forming mold 600 are pressed together, The dough and the stuffing are packaged and molded, and the forming mold 600 moves to the pushing station, and the pushing device 500 pushes out the formed food.

Embodiment 2

[0037] A food forming method provided with a split forming mold, comprising the following steps: After the dough is processed by a noodle supply device 200, it falls on a forming mold 600 located at a noodle supplying station, and the forming mold 600 moves to a filling station, injecting The stuffing device 300 injects the stuffing on the dough of the forming mold 600, the forming mold 600 continues to move to the forming station, the first forming plate 401 on the forming device 400 and the second forming plate 602 on the forming mold 600 are pressed together, The dough and the stuffing are packaged and molded, and the forming mold 600 moves to the pushing station, and the pushing device 500 pushes out the formed food.

[0038] While the first forming plate 401 and the second forming plate 602 on the forming die 600 are pressed together, the pressing block 605 on the forming die 600 squeezes the dough and the middle of the filling, such as the dumpling core part of the dumpli...

Embodiment 3

[0043] A food forming method provided with a split forming mold, characterized in that: after the dough is processed by the noodle supply device 200, it falls on the forming mold 600 located at the noodle supply station, and the forming mold 600 moves to the filling station, injecting The stuffing device 300 injects the stuffing on the dough of the forming mold 600, the forming mold 600 continues to move to the forming station, the first forming plate 401 on the forming device 400 and the second forming plate 602 on the forming mold 600 are pressed together, The dough and the stuffing are packaged and molded, and the forming mold 600 moves to the pushing station, and the pushing device 500 pushes out the formed food.

[0044] While the first forming plate 401 and the second forming plate 602 on the forming die 600 are pressed together, the pressing block 605 on the forming die 600 squeezes the dough and the middle of the filling, such as the dumpling core part of the dumpling. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com