High-pressure casting process of welding-free axial flow fan

A high-pressure casting and axial flow fan technology, applied in the field of high-pressure casting technology, can solve the problems of heavy weight of low-pressure casting impellers, low efficiency of performance parameters, lack of market competitiveness, etc., to reduce potential safety hazards, improve automation, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

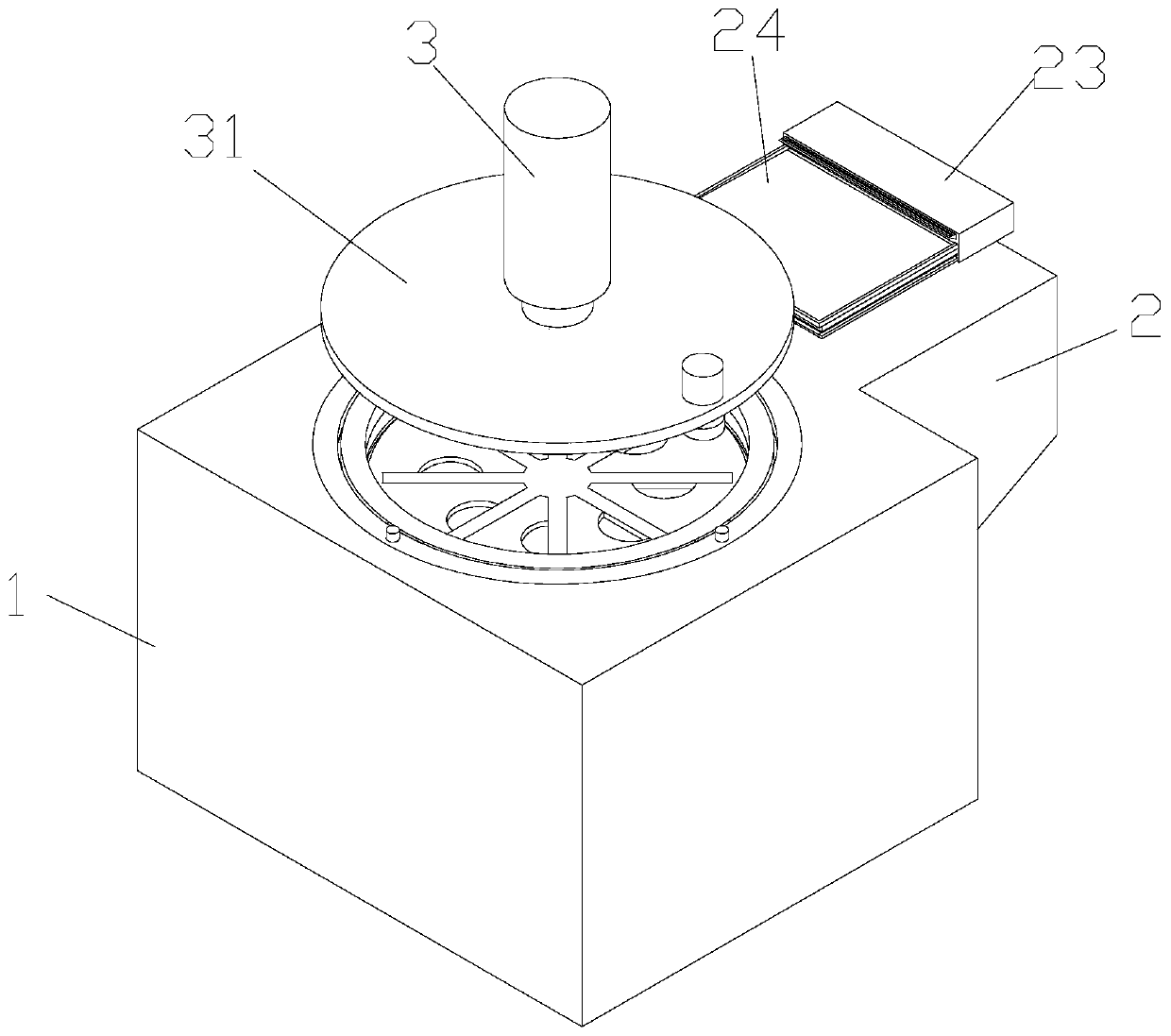

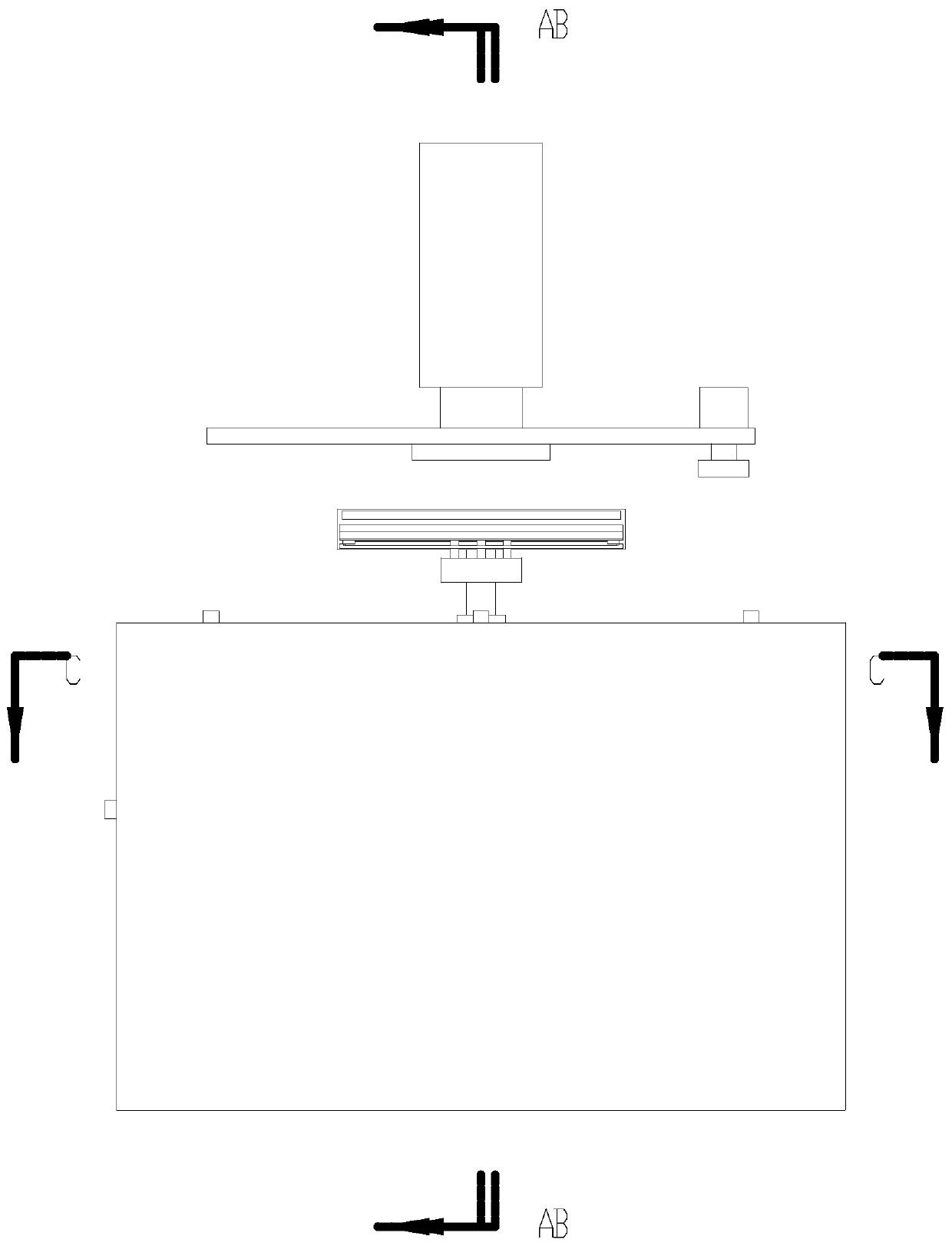

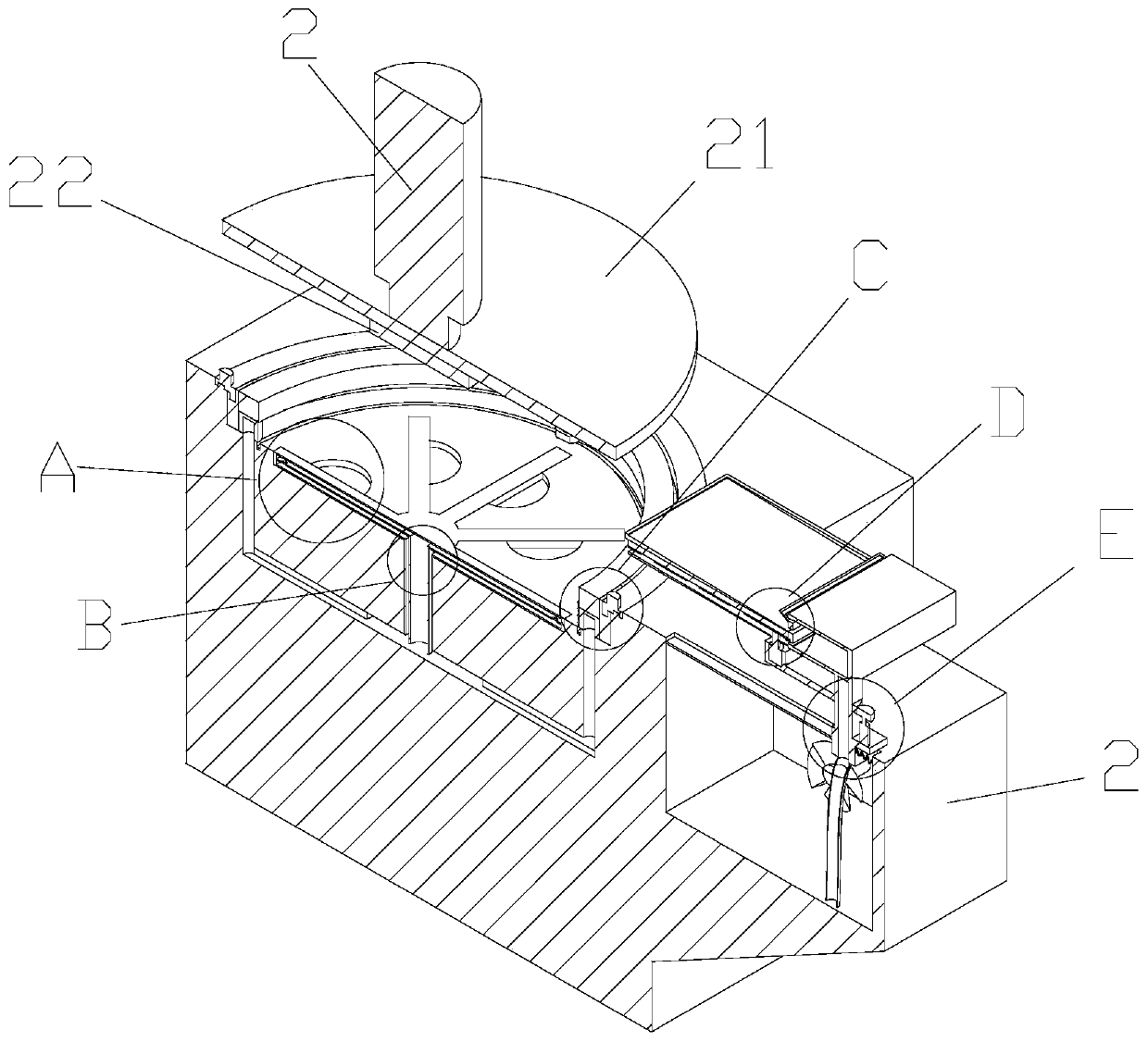

[0037] A high-pressure casting process for a non-welded axial flow fan, specifically the high-pressure casting process for the impeller, including: a. mold design and manufacture: design the shape of the mold according to the shape of the impeller, and complete the manufacture of the cone; b. installation of the mold And testing: put the mold into the casting machine, and test the performance index of the mold; c, mold pretreatment: after preheating the mold, spray paint on the inner wall of the mold; d, fit the mold Casting: After the upper and lower molds of the mold are combined, the metal in the molten state is injected into the mold; e, injection and cooling: reasonable control of the injection pressure to fill the entire mold with metal, and then cool the mold processing, so that the castings can be quickly formed; f, mold opening and picking: after the casting mold is completed, the upper and lower molds are opened, and the molded castings are directly taken out; g, qual...

Embodiment 2

[0063] A high-pressure casting process for a non-welded axial flow fan, specifically the high-pressure casting process for the impeller, including: a. mold design and manufacture: design the shape of the mold according to the shape of the impeller, and complete the manufacture of the cone; b. installation of the mold And testing: put the mold into the casting machine, and test the performance index of the mold; c, mold pretreatment: after preheating the mold, spray paint on the inner wall of the mold; d, fit the mold Casting: After the upper and lower molds of the mold are combined, the metal in the molten state is injected into the mold; e, injection and cooling: reasonable control of the injection pressure to fill the entire mold with metal, and then cool the mold processing, so that the castings can be quickly formed; f, mold opening and picking: after the casting mold is completed, the upper and lower molds are opened, and the molded castings are directly taken out; g, qual...

Embodiment 3

[0065] A high-pressure casting process for a non-welded axial flow fan, specifically the high-pressure casting process for the impeller, including: a. mold design and manufacture: design the shape of the mold according to the shape of the impeller, and complete the manufacture of the cone; b. installation of the mold And testing: put the mold into the casting machine, and test the performance index of the mold; c, mold pretreatment: after preheating the mold, spray paint on the inner wall of the mold; d, fit the mold Casting: After the upper and lower molds of the mold are combined, the metal in the molten state is injected into the mold; e, injection and cooling: reasonable control of the injection pressure to fill the entire mold with metal, and then cool the mold processing, so that the castings can be quickly formed; f, mold opening and picking: after the casting mold is completed, the upper and lower molds are opened, and the molded castings are directly taken out; g, qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com