A kind of reverse pressure relief dust-proof filter coal conveying belt conveyor

A technology of belt conveyor and filter mechanism, which is applied in the direction of conveyor, loading/unloading, transportation and packaging, etc., and can solve problems such as difficult collection and dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

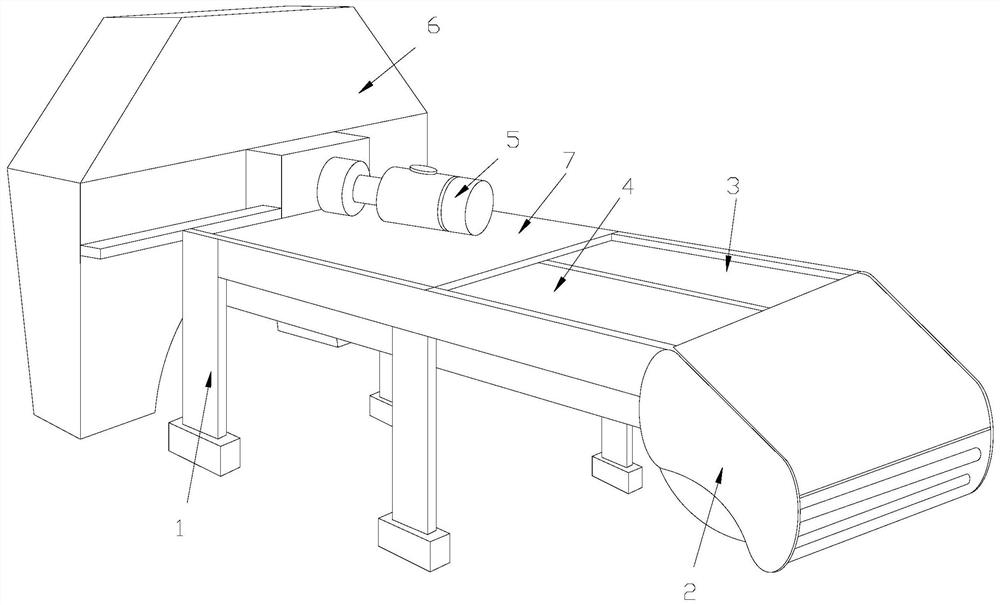

[0028] as attached figure 1 to attach image 3 Shown:

[0029] The present invention provides a coal conveying belt conveyor for pressure relief and dust-proof filtration, the structure of which includes a support frame 1, a pressure relief and dust-proof filtration device for reverse flushing 2, a side guard plate 3, a transmission belt 4, a motor 5, and a feeding sleeve 6. Flat plate 7, the support frame 1 is welded to the feeding sleeve frame 6, the top of the reverse pressure relief dust-proof filter device 2 is welded to the side guard plate 3, and the transmission belt 4 is arranged directly below the flat plate 7 , the bottom end of the motor 5 is fixedly connected with the flat plate 7, and the motor 5 is installed inside the feeding sleeve 6 in an embedded manner, and the feeding sleeve 6 is welded to the side guard plate 3.

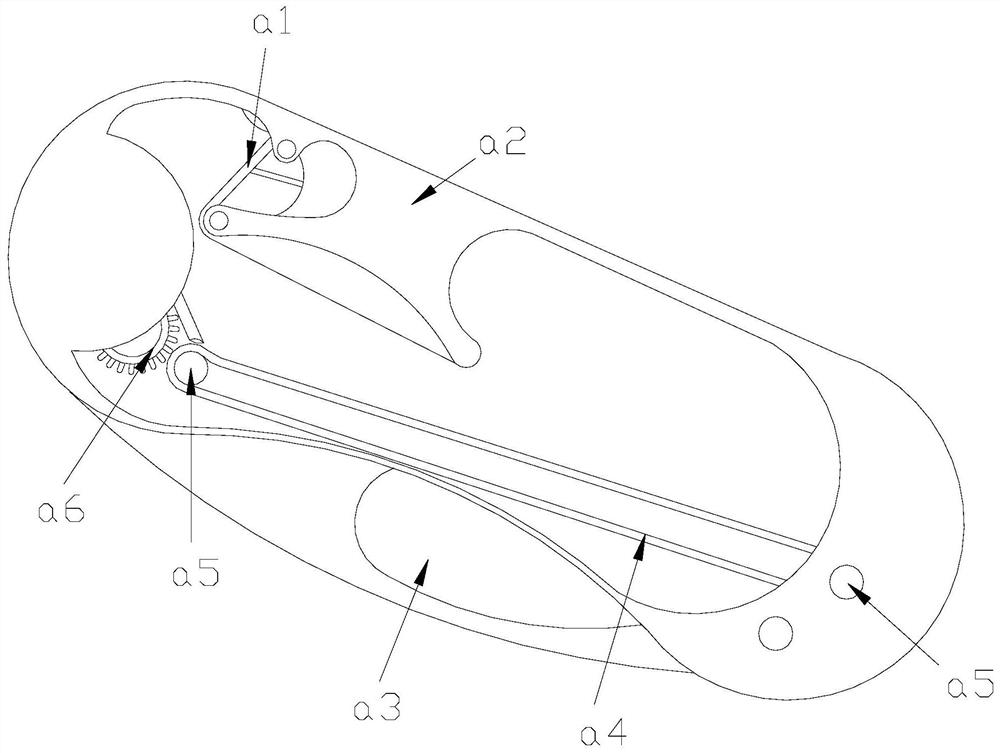

[0030] The backflush pressure relief dustproof filter device 2 includes a backflush dust caressing mechanism a1, an envelope a2, a dust coll...

Embodiment 2

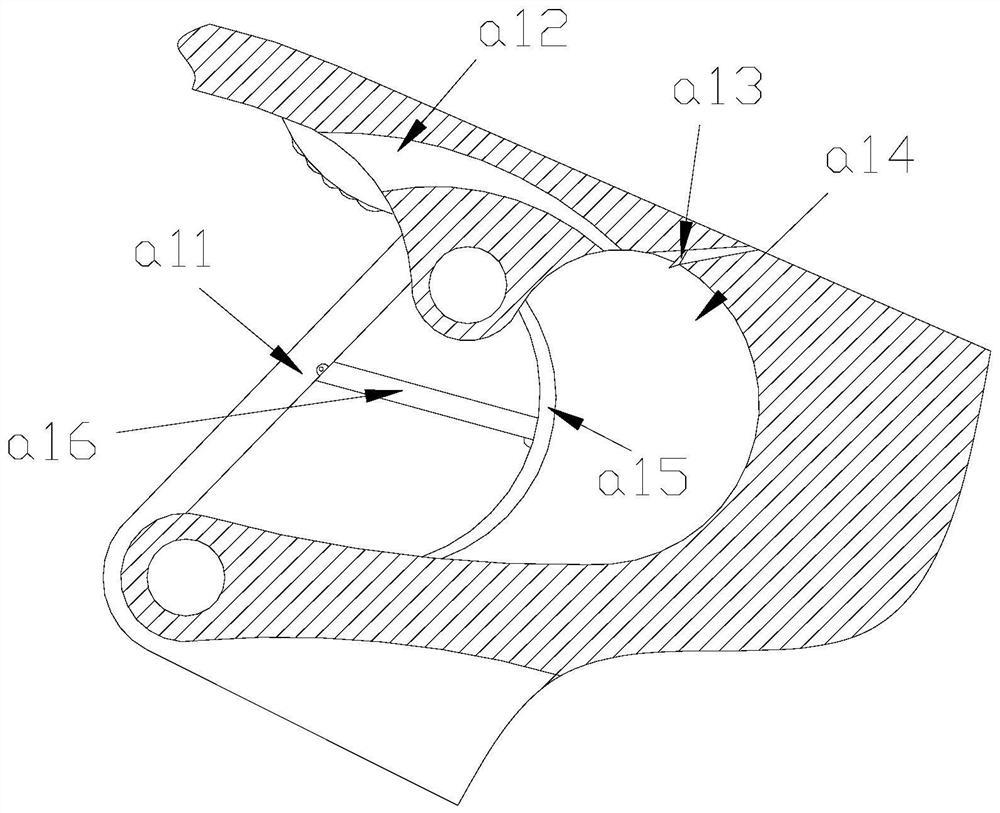

[0035] as attached Figure 4 To attach Figure 8 Shown:

[0036] The present invention provides a backwash pressure relief dust-proof filter coal conveying belt conveyor, the dust-proof filter mechanism a6 includes a pin joint a61, a filter mechanism a62, a built-in motor a63, a filter dust-through mechanism a64, and a turntable a65. The pin joint a61 is fixedly connected with the top of the filtering mechanism a62, the built-in motor a63 is embedded in the turntable a65, the filter and dust ventilation mechanism a64 is movably connected with the turntable a65, and the filtering mechanism a62 is located at the upper right end of the filter and dust ventilation mechanism a64, and the filter mechanism a62 is obliquely fixed on the envelope a2, and is mainly used to accept dumped carbon ore, and cooperates with the filter and dust ventilation mechanism a64 to pass through The driving of the built-in motor a63 and the turntable a65 to the filter and dust discharge mechanism a64 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com