Reinforced connecting bolt assembly and method for fastening plate body by bolt assembly

A technology for connecting bolts and reinforcement, applied in the direction of connecting components, threaded fasteners, bolts, etc., can solve problems such as splitting, cracking in the connecting area, and easy slippage, etc., to achieve a high degree of cooperation and improve the effect of fastening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

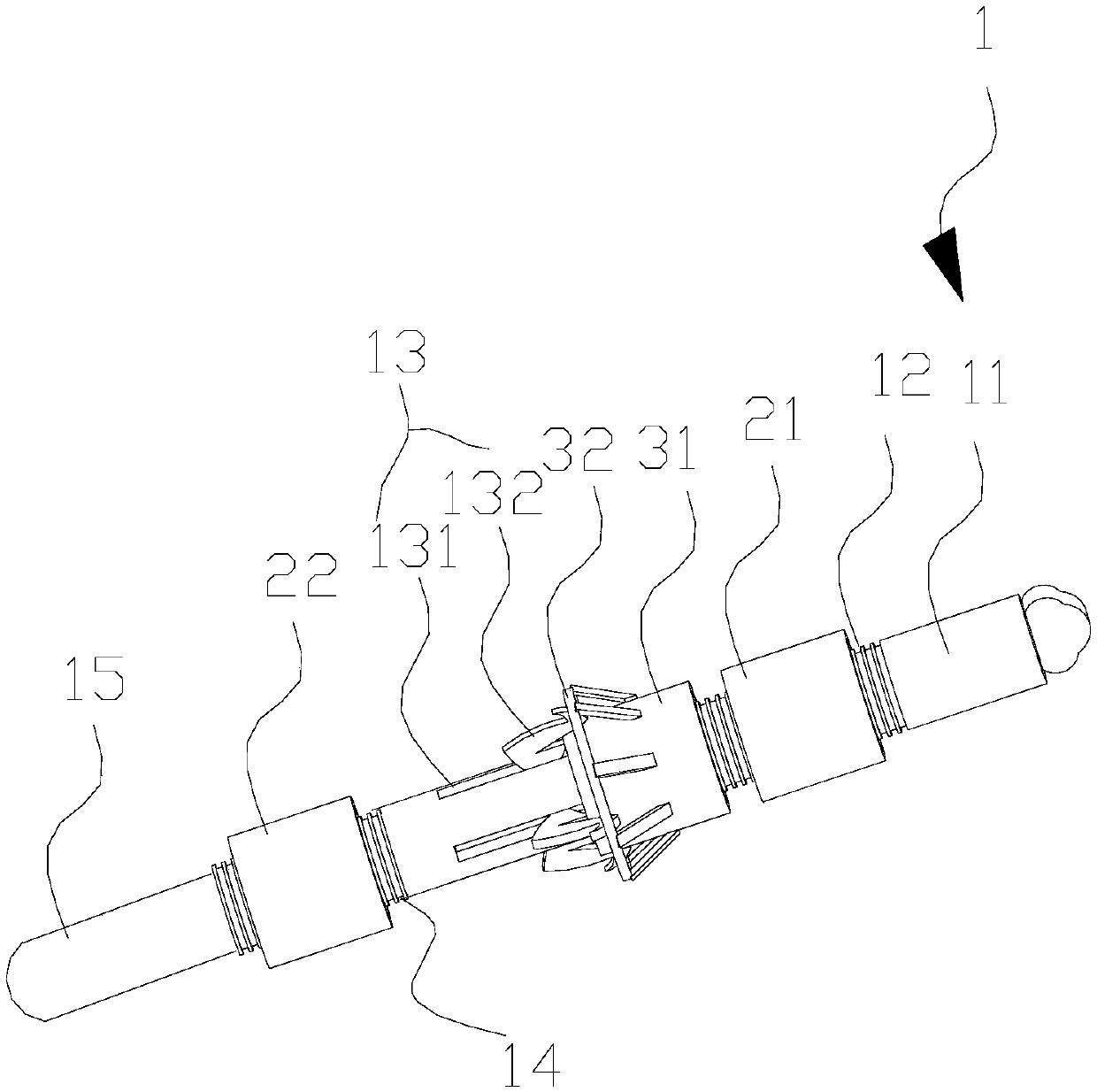

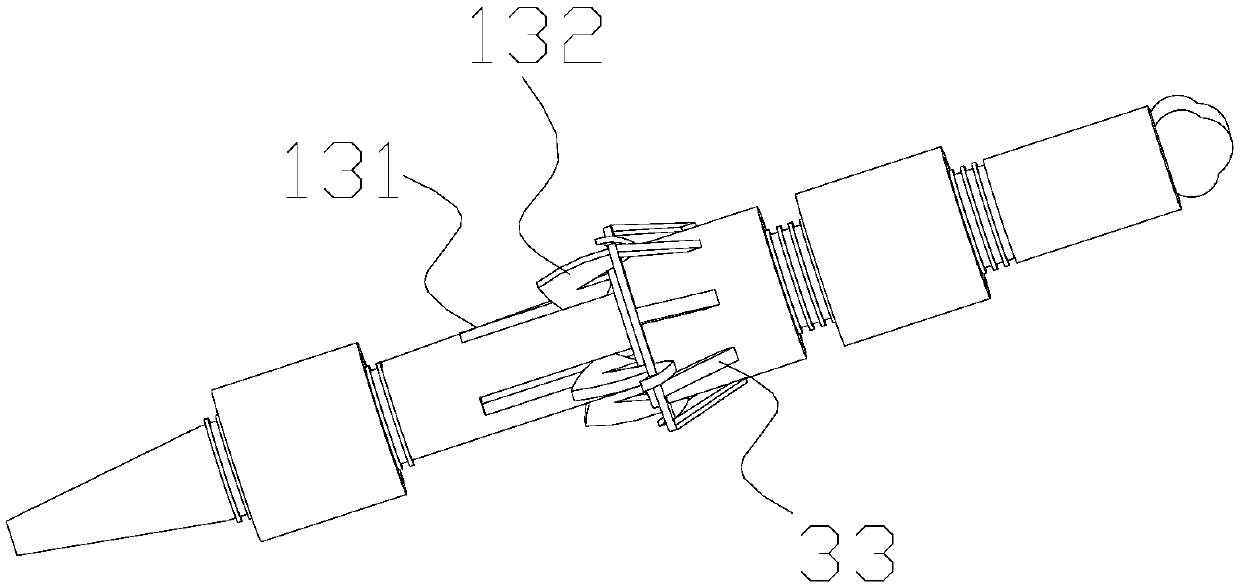

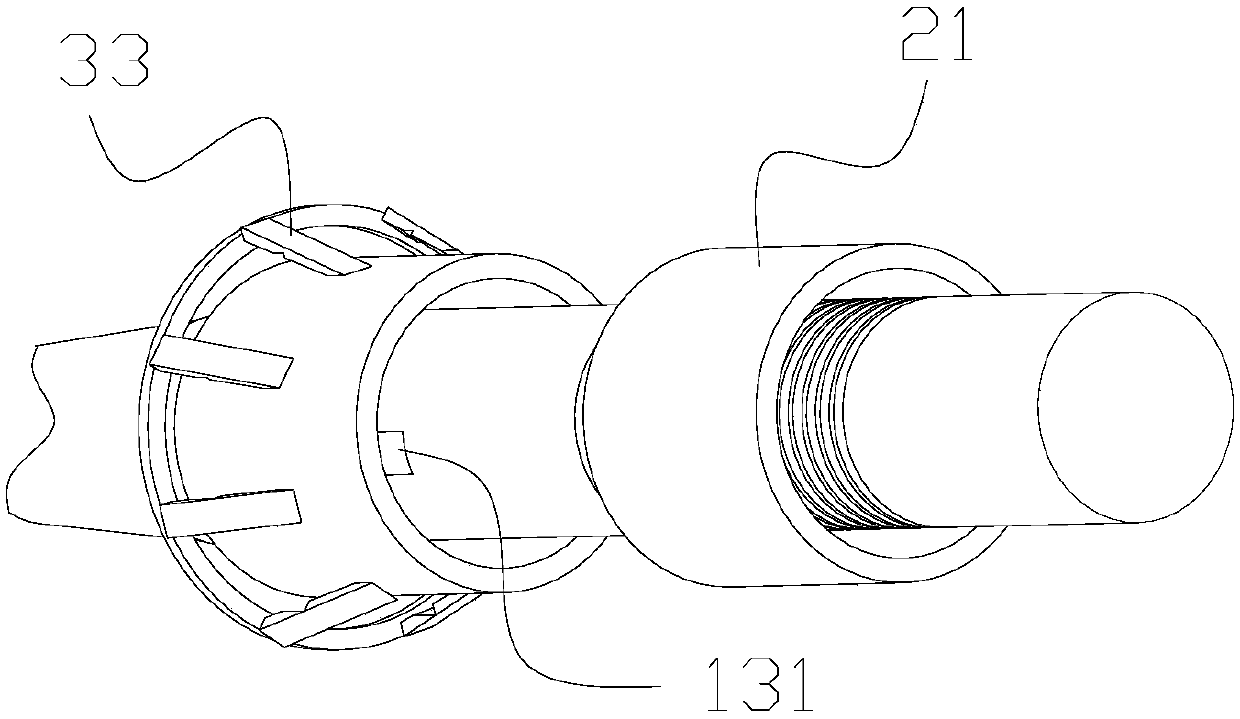

[0053] like Figure 1-3 As shown, this embodiment discloses a reinforced connecting bolt assembly, which includes a bolt body 1 and a nut threaded with the bolt body 1 . Also includes a fastening ring assembly, the fastening ring assembly includes a first annular ring 31, a second annular ring 32, the second annular ring 32 is concentric with the first annular ring 31 and the inner diameter of the second annular ring 32 is larger than the first annular ring 31 the outer diameter. The bolt body 1 sequentially includes a rotating rod part 11 , a first threaded rod part 12 , a clamping rod part 13 , a second threaded rod part 14 and a bottom rod part 15 along its axial direction from the front to the rear part. The nuts include a first nut 21 and a second nut 22 with the same specification, the first threaded rod part 12 cooperates with the first nut 21 , and the second threaded rod part 14 cooperates with the second nut 22 .

[0054] like figure 2 , 4 As shown, the clamping...

Embodiment 2

[0066] like Figure 1-3 As shown, the difference between the present embodiment and the above-mentioned embodiments is that each of the clamping rods 13 includes a plurality of receiving grooves 131 , and the plurality of receiving grooves 131 in the clamping rod 13 are arranged in a ring shape.

[0067] In the present invention, a plurality of receiving grooves 131 are provided, so that after all the clamping parts 132 are rotated out from the corresponding receiving grooves 131, an umbrella shape is formed, and a plurality of angular openings can cooperate with a plurality of barbs to be connected with the first annular ring 31, The second annular ring 32 is fastened to achieve the technical effects of multi-point stress and increased clamping and fastening area.

Embodiment 3

[0069] like Figure 4 As shown, the difference between this embodiment and the above-mentioned embodiments is that the hook part 1323 is hinged to the movable part 1322 through the second shaft, and the second torsion spring (not shown in the figure) is assembled so that the hook part 1323 is connected to the first movable part 1322 Acute angle openings are formed between them.

[0070] The present invention uses a torsion spring as a reset member. Of course, the elastic material in the prior art can also be directly connected to the movable part 1322 as the hook part 1323. When receiving an external force, the variable capacity of the elastic material is used to expand the opening. However, compared with elastic materials, the hook portion 1323 of the present invention can be made of a material with high modulus, high strength, and little deformation, such as a steel block, by using a torsion spring as a reset member. It is not easy to be deformed, and can further ensure the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com