Ammunition clamping device

A clamping device and ammunition technology, which is applied in ammunition, offensive equipment, weapon accessories, etc., can solve the problems of high rigidity and easy slipping of the jaws, and achieve the effect of large clamping force, reasonable layout and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

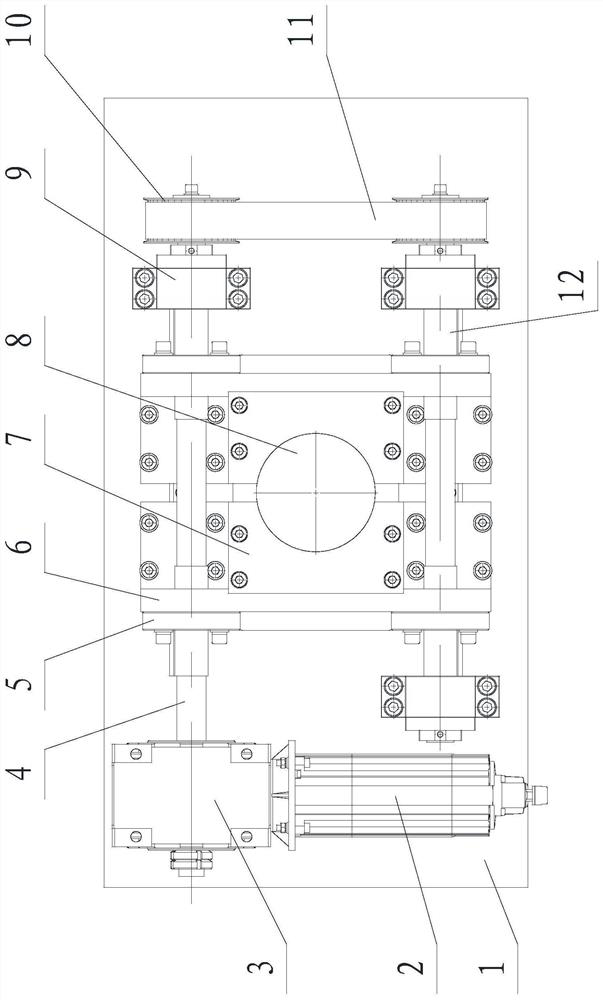

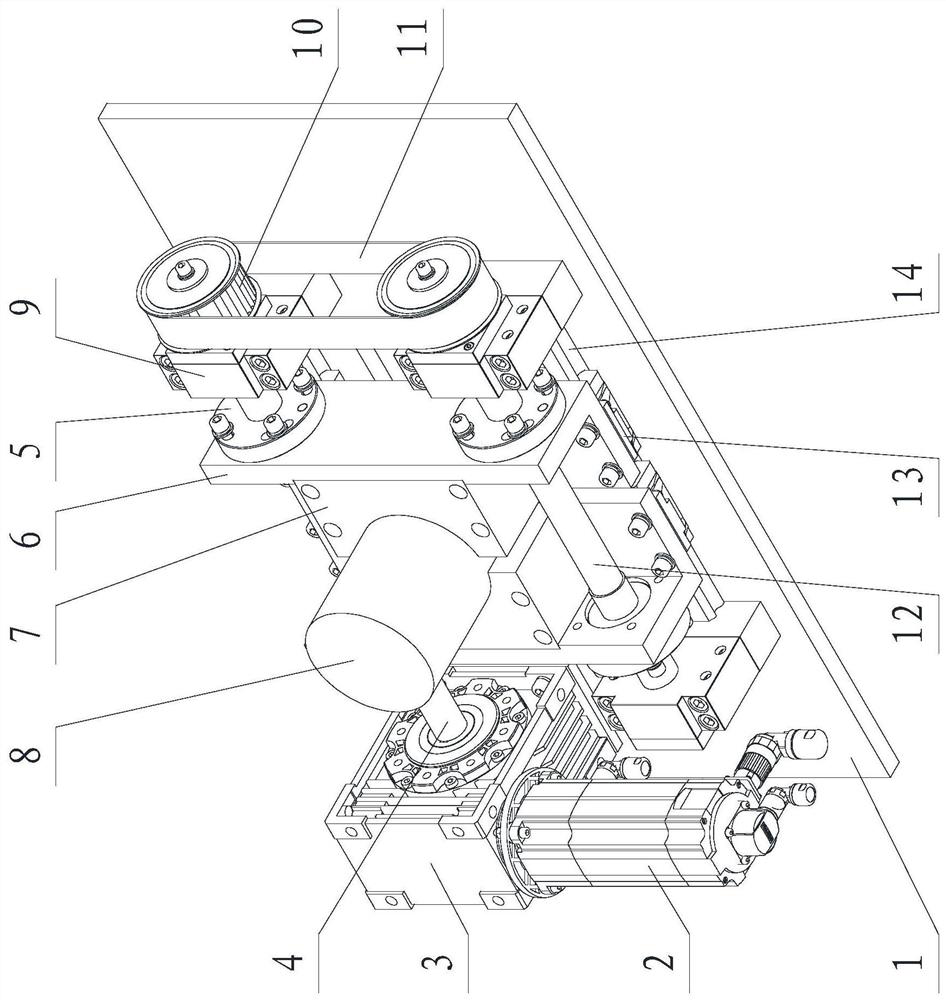

[0024] Such as figure 1 , figure 2 As shown, the present invention includes installation base 1, power source, shaft A4, nut 5, jaw mounting plate 6, jaw 7, rotary support 9, transmission mechanism, shaft B12 and guide mechanism, wherein shaft A4 and shaft B12 are respectively Installed on the installation base 1 through the rotary support 9, the axis A4 and the rotary support 9 and the shaft B12 and the rotary support 9 are connected in rotation, and the axis A and the axis B are parallel to each other; one end of the axis A4 / axis B12 is connected to the installation The output end of the power source on the installation base 1 is connected, and the other end is connected with the shaft B12 / axis A4 through the transmission mechanism; the power source drives the shaft A4 / axis B12 to rotate, and drives the shaft B12 / axis A4 to rotate synchronously and in the same direction through the transmission mechanism. The power source of this embodiment includes a motor 2 and a reducer...

Embodiment 2

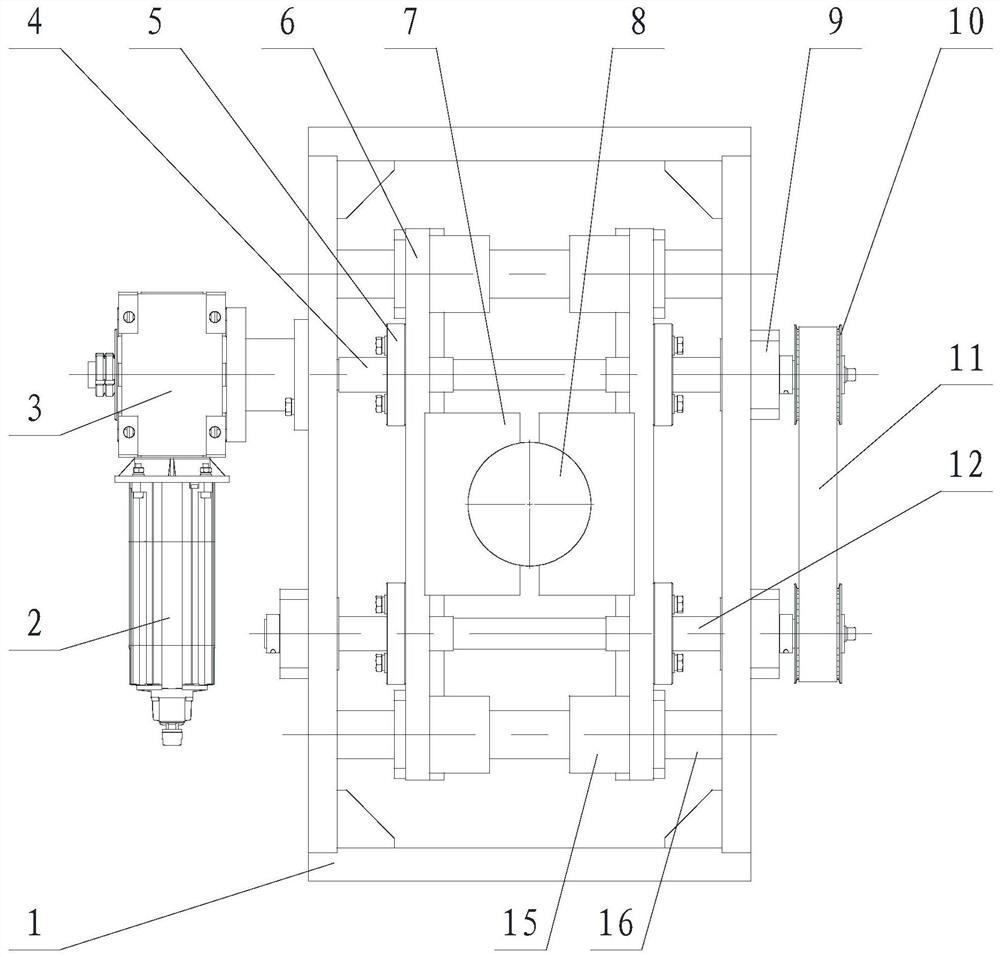

[0028] Such as image 3 , Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the installation base 1 of this embodiment is a square frame structure, and the rotary support 9, the nut 5, the jaw mounting plate 6, and the jaws 7 are respectively installed on the two sides of the frame. and the guiding mechanism are all located in the square frame, and the transmission mechanism and the power source are all located outside the square frame. The guiding mechanism of this embodiment includes a linear bearing 15 and an optical axis 16, the optical axis 16 is installed on the installation base 1, and each jaw mounting plate 6 is connected with a linear bearing 15 (there are four linear bearings 15 in total). The jaw mounting plate 6 is slidably connected with the optical axis 16 through a linear bearing 15 . In this embodiment, one optical axis 16 is provided above the axis A4 and below the axis B12 respectively, and the two optical axes 16 are para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com