Service life testing machine for tubular motor

A life test, tubular motor technology, applied in the direction of motor generator testing, electrical measuring instrument parts, measuring electricity, etc., can solve the problem that the load mechanism cannot use the tubular motor, the test effect is poor, and the installation is difficult, etc. Clamping stability and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

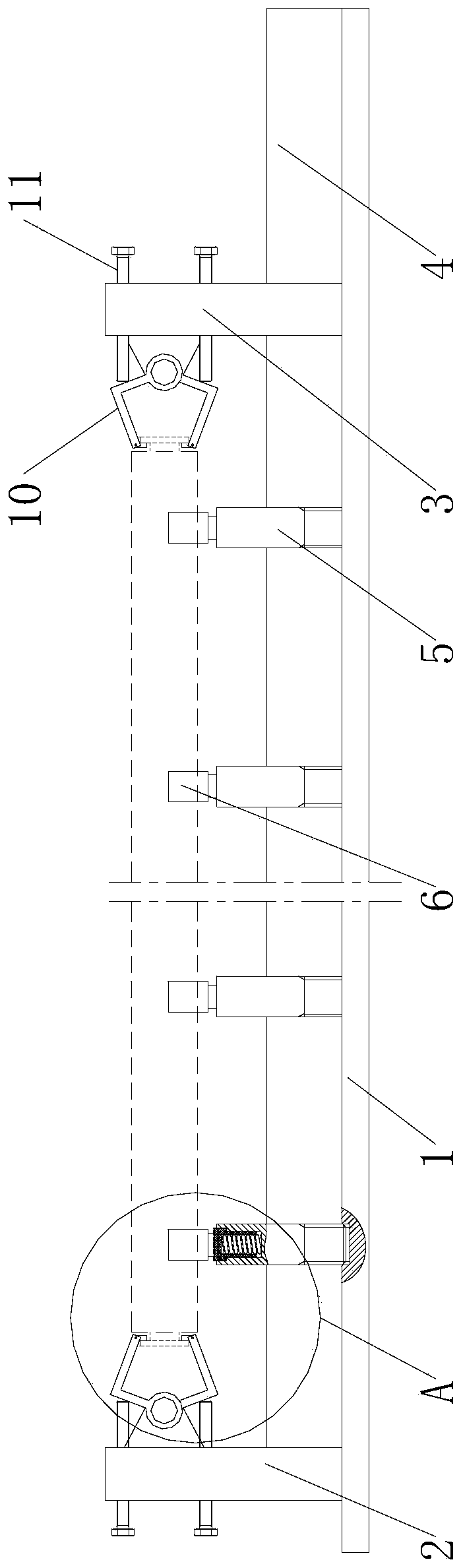

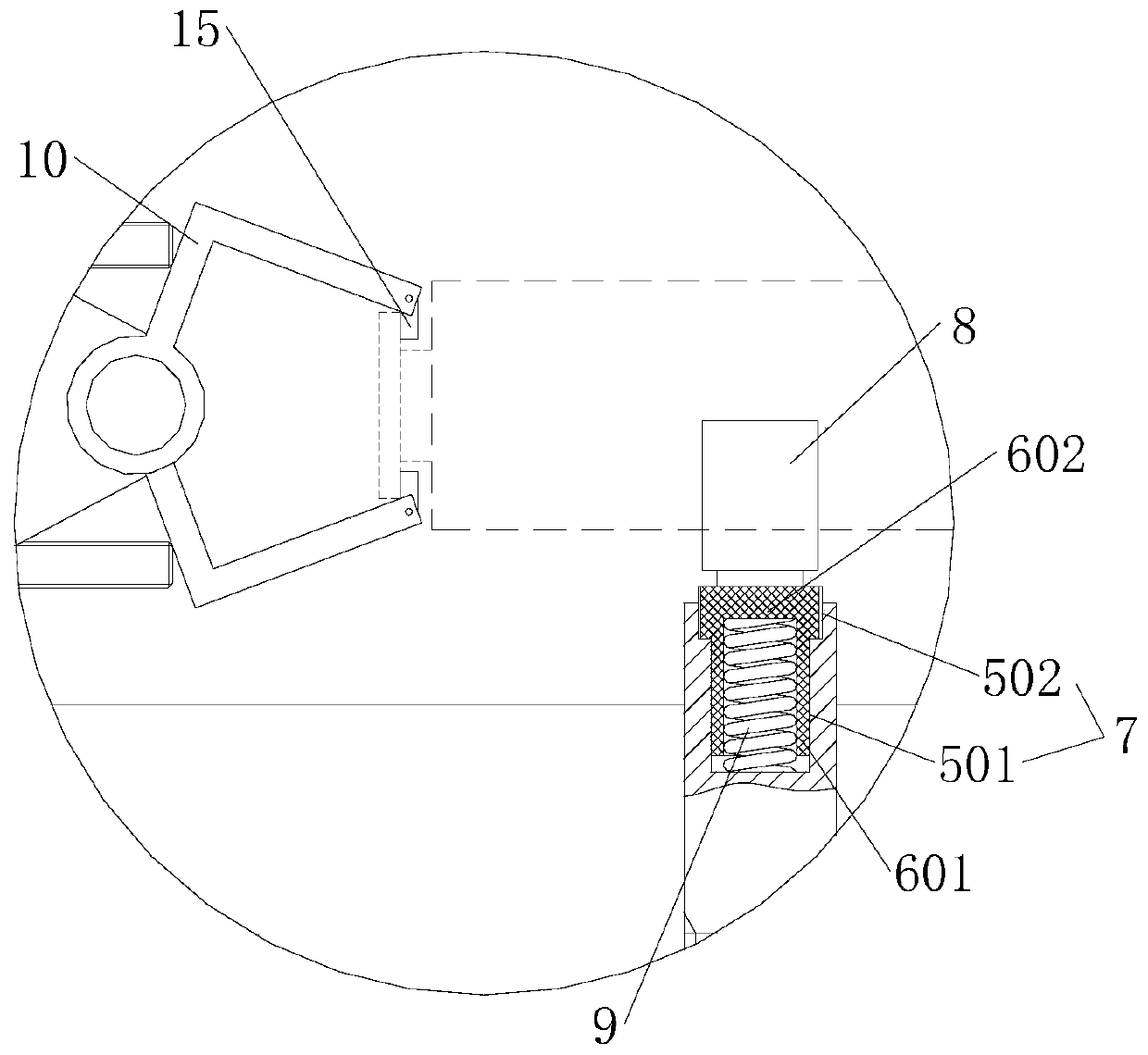

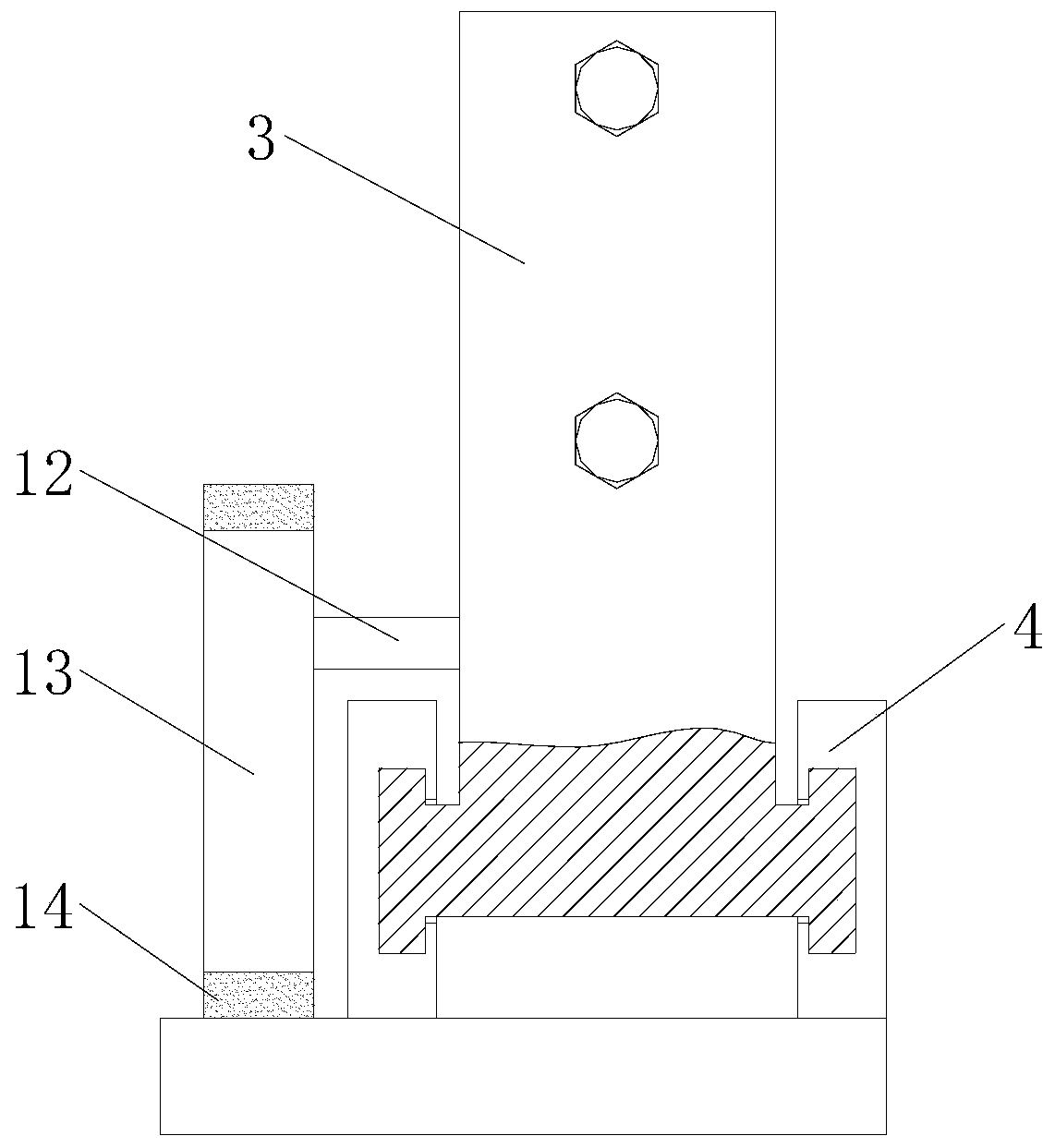

[0019] Example. A tubular motor life testing machine, constituted as figure 1 As shown, the test platform 1 is included, the test platform 1 is respectively provided with a fixed seat 2 and a movable seat 3, the outer side of the fixed seat 2 is provided with a drive power supply, and the two sides of the lower end of the movable seat 3 are connected to the test platform 1 through the guide rail 4, and the fixed seat 2 and the moving base 3 are provided with a clamping assembly, one side of the moving base 3 is provided with a limit assembly, and a pressure assembly is provided on the test platform 1 between the fixed base 2 and the moving base 3, and the pressure assembly is located in the vertical direction. The middle position of the guide rails 4 on both sides; the pressure assembly includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com