All-element micro-module IDC machine room powered by high-voltage direct-current 2N

A high-voltage direct current, micro-module technology, applied in the direction of electrical components, circuit devices, emergency power supply arrangements, etc., can solve the problems of large power loss, increased energy consumption, and decreased efficiency of power supply equipment, so as to reduce costs and reduce power conversion. The effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

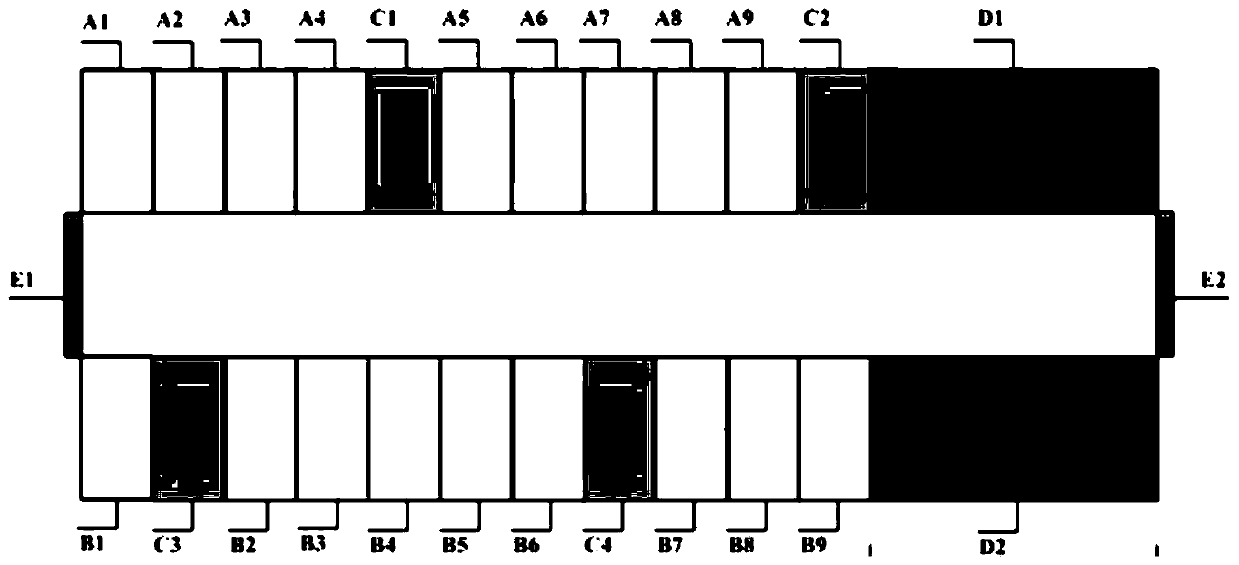

[0026] refer to figure 1 , the number of components in this embodiment is preferably as follows: the number of IT cabinets is 18, the double rows are arranged face to face at an interval of 1.2 meters, the cabinet size is 600mm wide*1200mm deep*2200mm high, the maximum power density of a single cabinet is 10kW; the cooling capacity is 50kW naturally The number of cold air-cooled fluorine pump DC frequency conversion inter-row air-conditioning units is 4, of which the size of the indoor unit is 600mm wide * 1200mm deep * 2200mm high, interspersed with IT cabinets and evenly deployed in the micro-module computer room. Including the first IT cabinet A1 of the north row; the second IT cabinet A2 of the north row; the third IT cabinet A3 of the north row; the fourth IT cabinet A4 of the north row; the fifth IT cabinet A5 of the north row; the sixth IT cabinet A6 of the north...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com