Scrubber water tank battery module rapid replacement platform and working method thereof

A battery module and washing machine technology, which is applied in the directions of carpet cleaning, floor cleaning, machine parts, etc., can solve the problems of high labor intensity, low replacement efficiency of the battery module of the washing machine water tank, and inability to take into account battery charging at the same time. The effect of low strength, high degree of automation and high replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

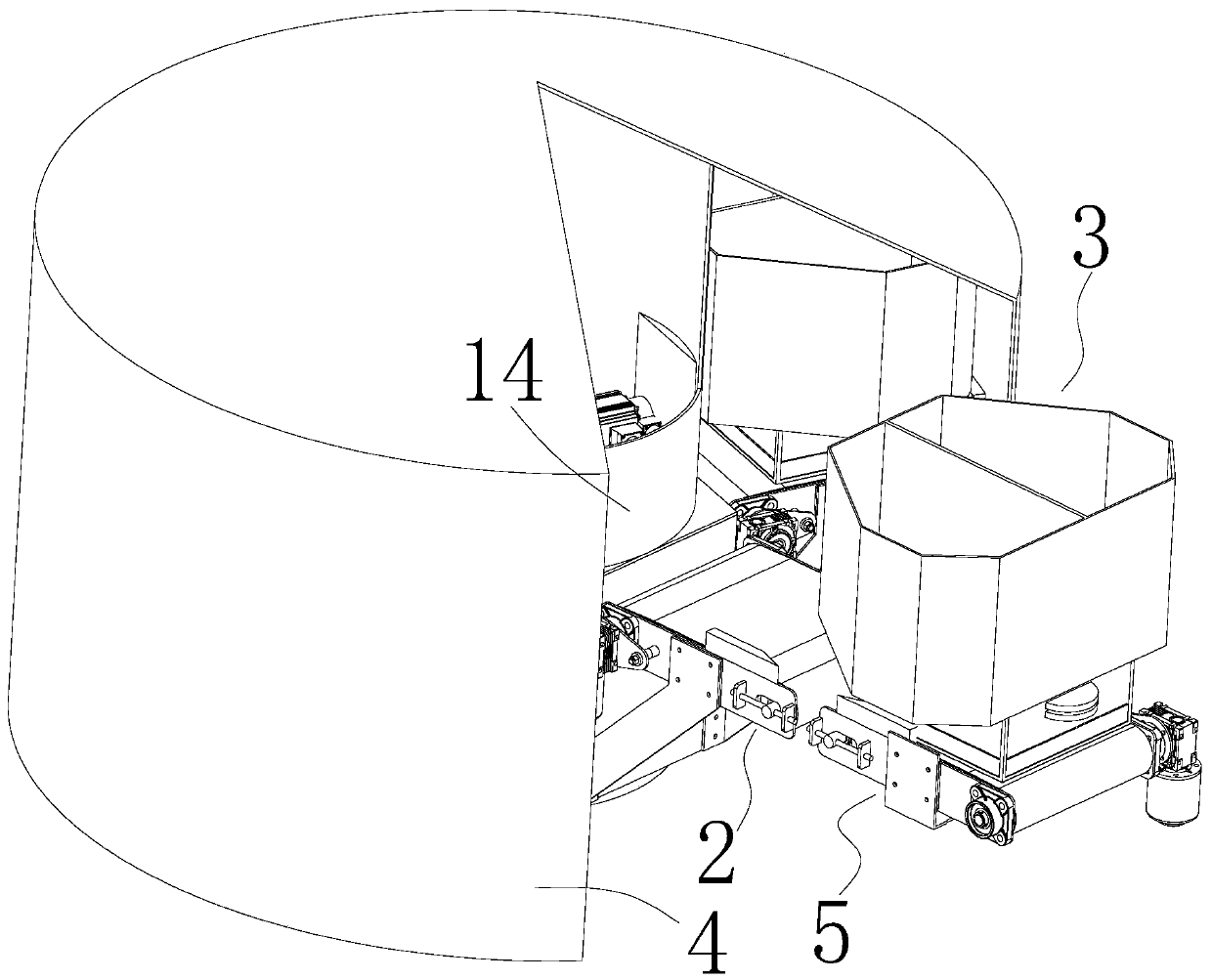

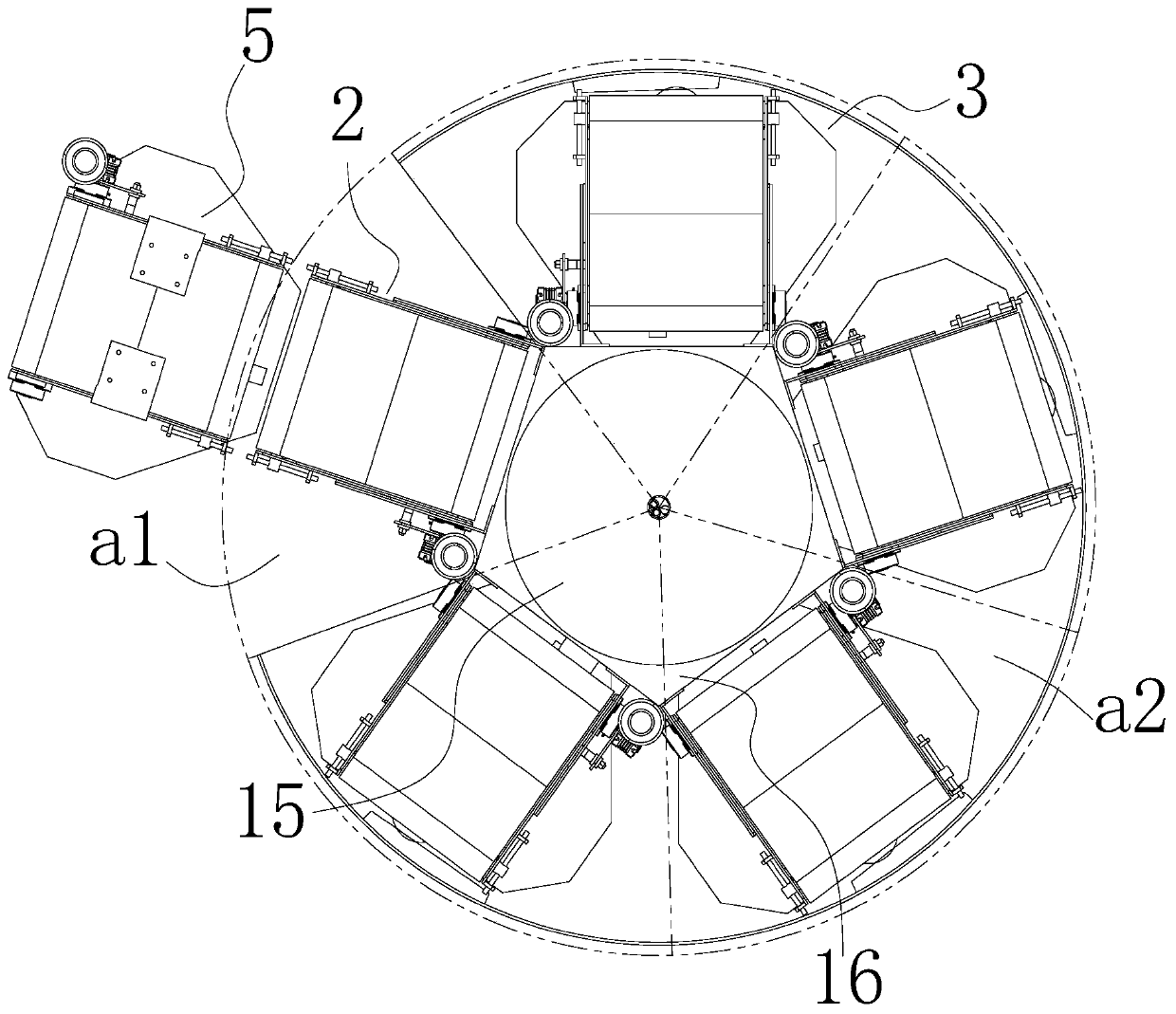

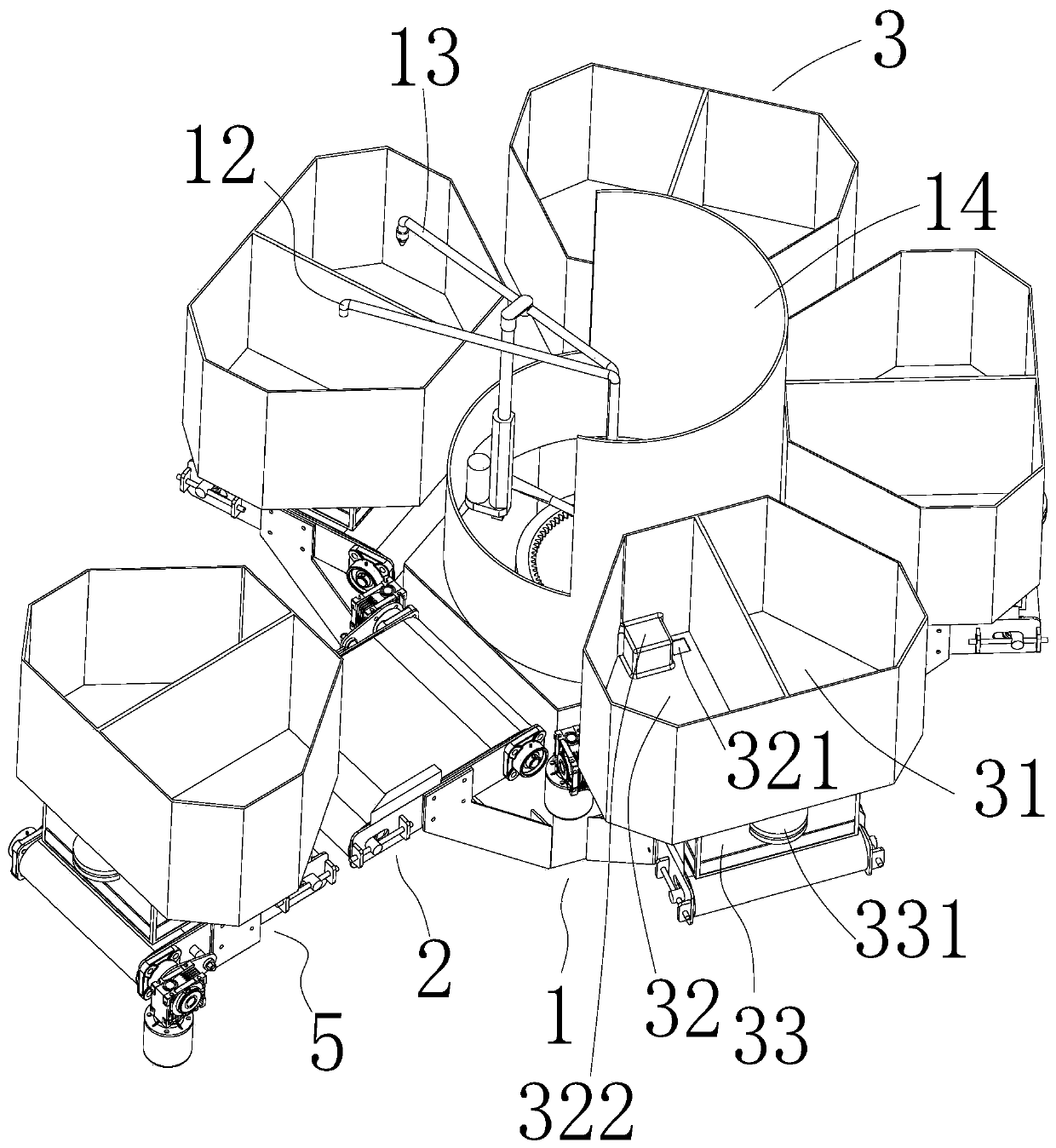

[0059] Such as Figure 1-3 As shown, a platform for quickly replacing the battery module of the washing machine water tank includes a replacement station a1, a supply station a2, a rotating mechanism 1, a transmission mechanism 2, a water tank battery module 3, a casing 4, and a washing machine transmission mechanism 5.

[0060] Such as figure 1 , 15 As shown, the casing 4 covers the rotating mechanism 1, the transmission mechanism 2, and the water tank battery module 3. The casing 4 includes upper and lower parts, the upper part is a conical casing, and the lower part is a cylindrical casing. The axis of the casing 4 is along the vertical direction, and the casing 4 is located at the replacement station a1 to provide a gap for the battery module 3 of the water tank to enter and exit.

[0061] Such as Figure 4 , 5 As shown, the rotation axis of the rotation mechanism 1 is along the vertical direction, and the rotation part of the rotation mechanism 1 is provided with at l...

Embodiment 2

[0081] The present invention also discloses a working method applied to the above-mentioned rapid replacement platform for the battery module of the washing machine water tank, including the following steps:

[0082] s1, such as Figure 4 As shown, the washing machine runs to the replacement station a1, and ensures that the transmission mechanism 5 of the washing machine corresponds to the position of the transmission mechanism 2 at the replacement station a1, that is, ensures the transmission between the washing machine transmission mechanism 5 and the replacement station a1. The mechanism 2 cooperates to be able to transport the water tank battery module 3 on the washing machine to the transmission mechanism 2 at the replacement station a1. Specifically, the transmission mechanism 5 of the washing machine and the transmission mechanism 2 at the replacement station a1 operate synchronously. And the transmission direction of the two points to the inner side of the rotating mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com