Desulfurization synergistic device

A technology for processing cylinders and cylinders, which is applied in the field of machinery, can solve problems such as unsatisfactory effects, difficult control of strength, and insufficient swirl strength, and achieve high stability and applicability, broaden the working range, and improve swirl effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

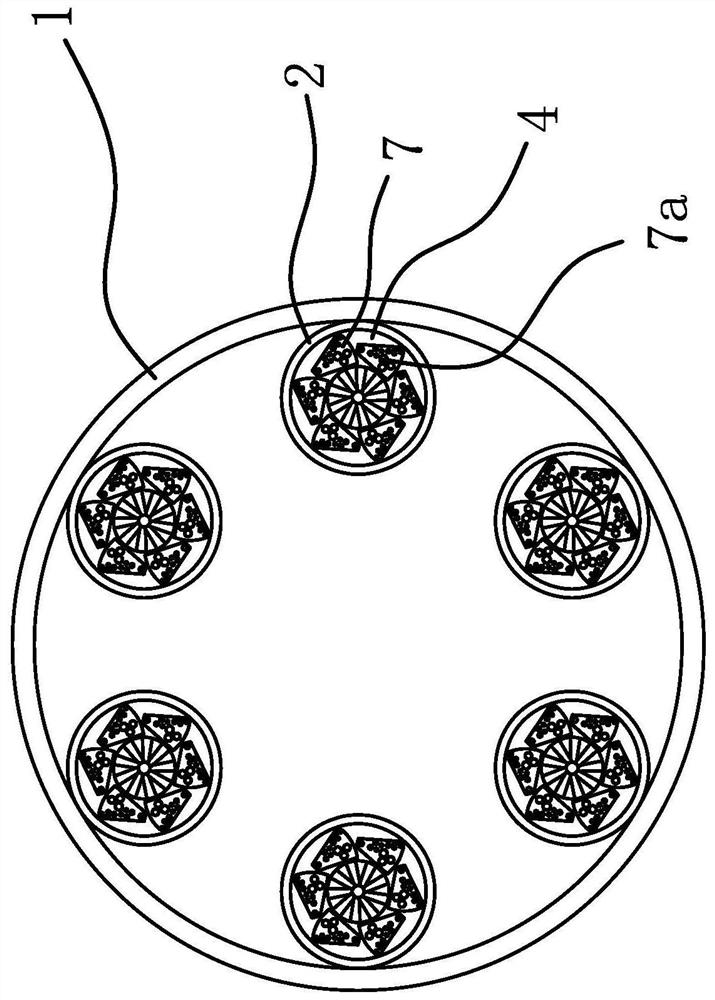

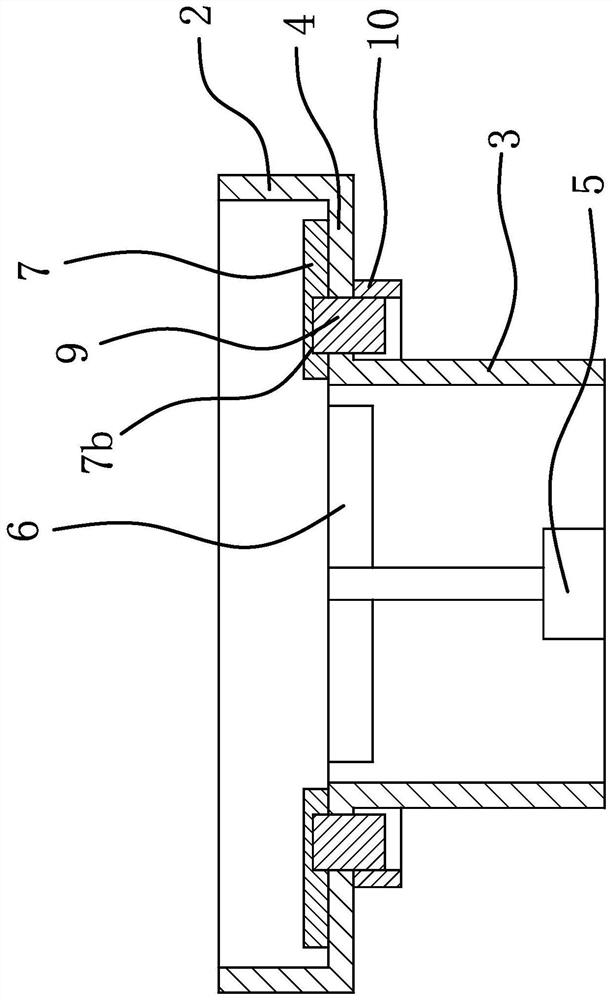

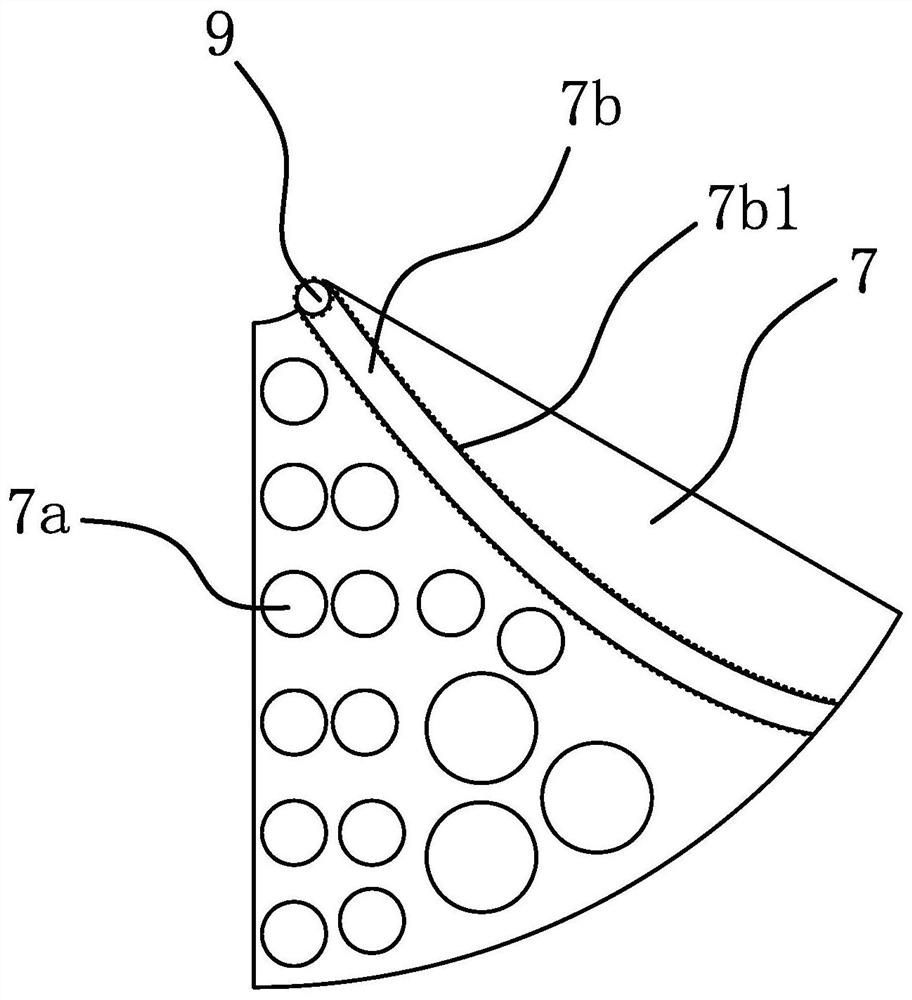

[0028] Such as figure 1 and figure 2 As shown, the desulfurization synergistic device includes a cylindrical shell 1, and also includes several cylindrical processing cylinders, and the processing cylinders have an impeller assembly that allows the flue gas to enter the other end from one end of the processing cylinder. The port of the processing cylinder has a strengthening processing assembly capable of opening and closing the port, the number of the above processing cylinders is several, and the several processing cylinders are all located in the casing.

[0029] The processing cylinder includes a cylindrical body 1 2 and a body 2 3, the inner diameter of the body 2 is greater than the inner diameter of the body 2 3, the inner side of the lower end of the body 2 has an annular protruding connecting portion 4, The upper end of the cylinder two 3 is fixedly connected to the connecting portion 4 and the cylinder one 2 communicates with the cylinder two 3 .

[0030] Above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com