Small direct current motor shaft length detection device and method

A technology of DC motor and detection device, applied in sorting and other directions, can solve the problems of unaccurate control of shaft length, large radial force, motor shaft fracture, etc., and achieve the effect of improving detection efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

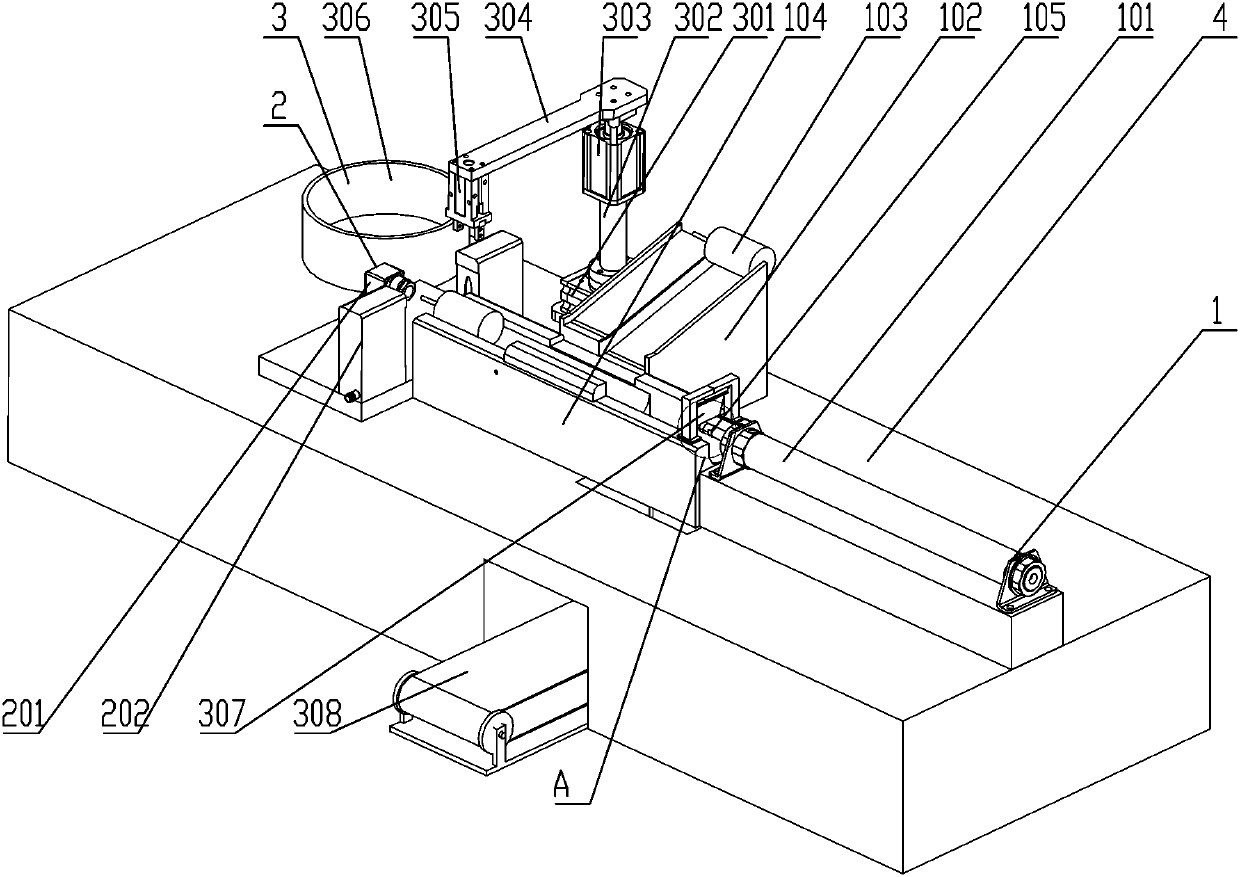

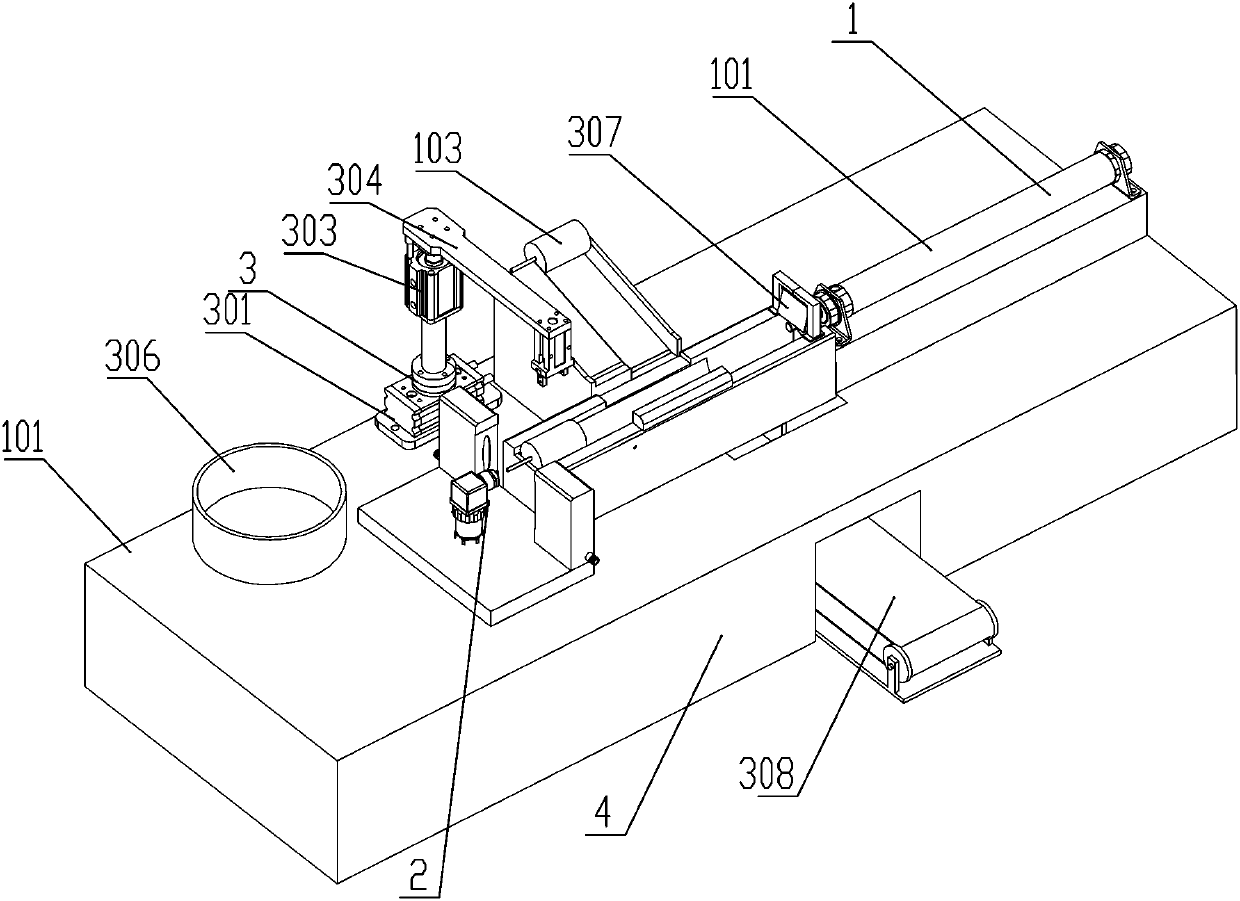

[0040] see Figure 1-5 , a small DC motor shaft length detection device, which includes a workbench 4, the top of the workbench 4 is fixedly installed with a feeding mechanism 1 for conveying the small DC motor to be detected, and the end of the feeding mechanism 1 is installed with a The detection mechanism 2 that detects the detection of small DC motors is equipped with a sorting mechanism 3 for sorting products on the side of the detection mechanism 2. The detection device of the above-mentioned structure can be used for the detection of the shaft length of the small DC motor 103, and it adopts the mode of automatic detection, and then greatly improves its detection efficiency and quality; After being sent to the detection area, the detection sensor detects the shaft length of the motor to judge whether the small DC motor is qualified, and then distinguishes qualified products from unqualified products through the classification mechanism, thus realizing the small DC motor ...

Embodiment 2

[0049] The method for detecting the shaft length detection device of the small DC motor is characterized in that:

[0050] Step1: Roll the small DC motor 103 to be detected from the feeding ramp 102 of the feeding mechanism 1 to the U-shaped groove 104 along the slope, and maintain the initial posture;

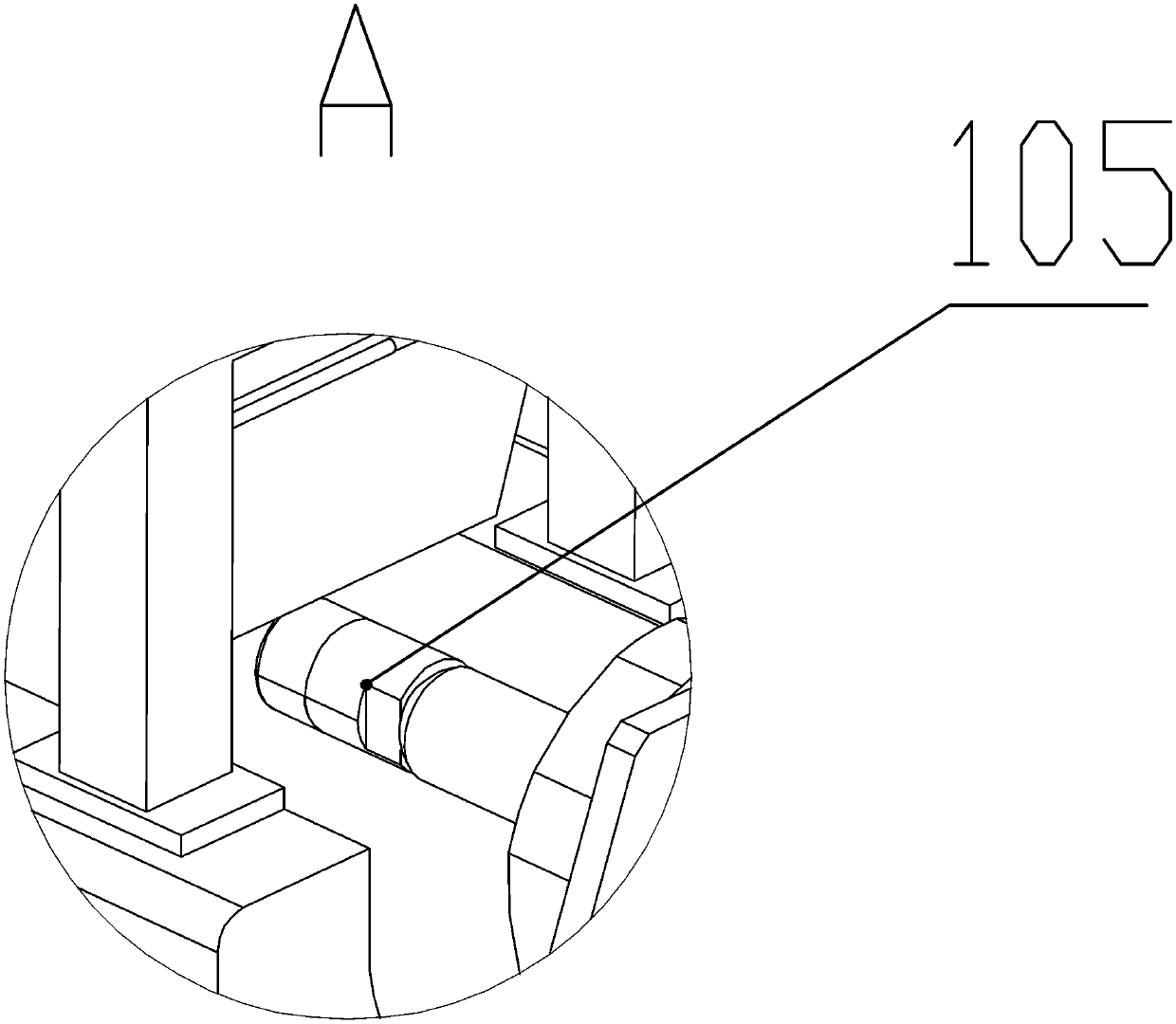

[0051] Step2: Start the pushing cylinder 102, its piston rod stretches out, the magnet 105 at the end of the piston rod absorbs the small DC motor and pushes it to the left end along the U-shaped groove 104, and the leftmost end of the U-shaped groove 104 is provided with a baffle plate, Small DC motor 103 is pushed to stop here;

[0052] Step3: Detect the length of the main shaft of the small DC motor 103 through the pressure sensor 201 and the through-beam photoelectric sensor 202 of the detection mechanism 2;

[0053] Step4: When it is detected that the small DC motor 103 is unqualified, the magnet 105 at the end of the piston rod of the pushing cylinder 101 is released an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com