Stirring head with depth variation for stirring area of friction stir welding

A technology of friction stir welding and stirring zone, which is used in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of stirring in the stirring zone, the friction effect is not good, and the welded joints are prone to defects, so as to avoid tunnel-type defects, Increase the effect of stirring and heat generation, and improve the effect of stirring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

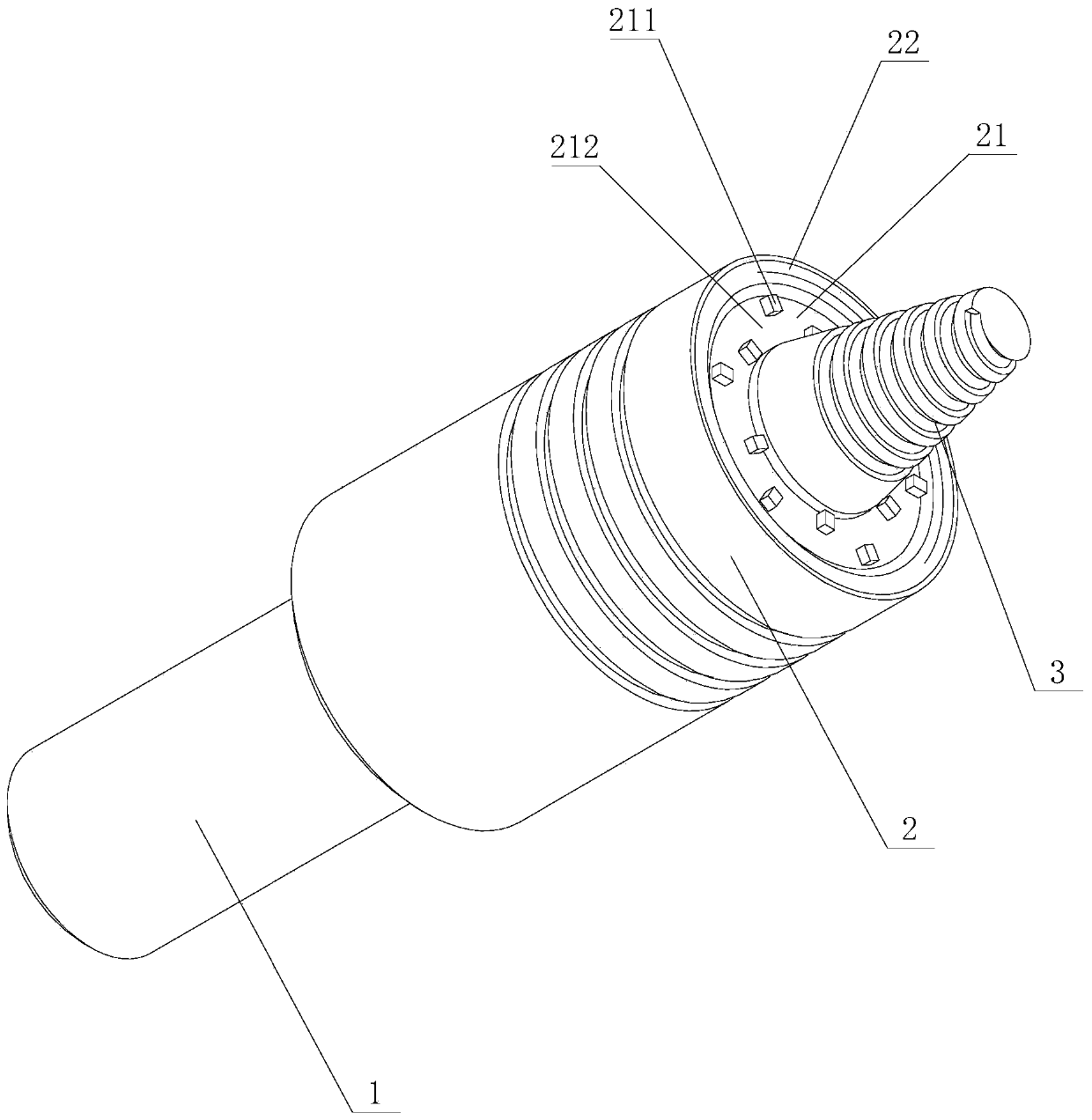

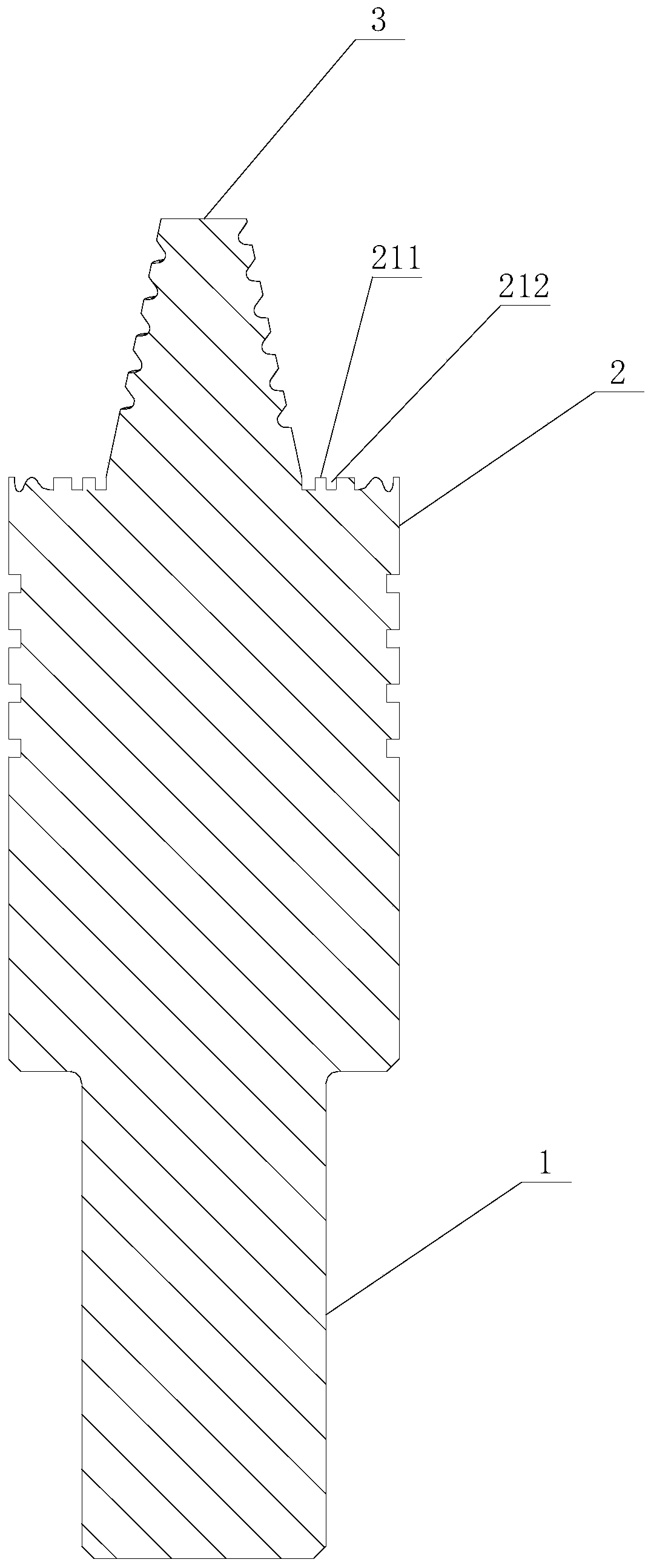

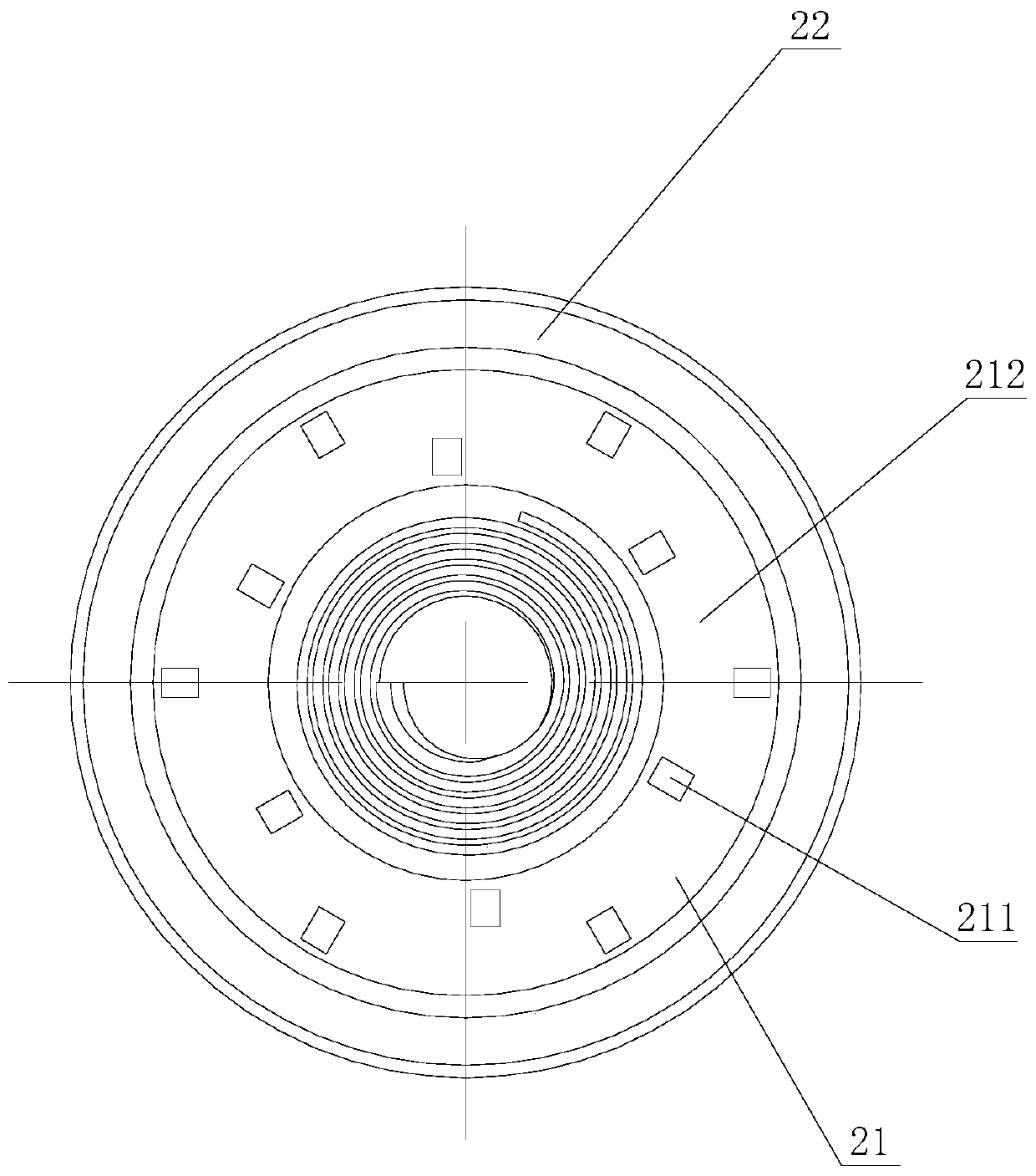

[0029] Such as Figure 1 to Figure 3 As shown, the first embodiment of the stirring head used in the friction stir welding of the present invention has a depth-changing stirring head, including a clamping part 1, a shaft shoulder part 2 and a stirring needle 3 connected in sequence, and the end surface of the shaft shoulder part 2 Including the enveloping area 22 away from the stirring needle 3 in the radial direction, the end surface of the shoulder 2 also includes a stirring area 21 for increasing the frictional moment and having a depth change at least in the circumferential direction, the stirring area 21 is in the radial direction close to the stirring needle 3. In this structure, the enveloping area 22 is set as a gentle surface, which is beneficial to wrapping and forging plastic metal; and the stirring area 21 has a depth-changing structure at least in the circumferential direction, and the depth-changing structure can effectively improve the friction when the stirring...

Embodiment 2

[0033] Such as Figure 4 to Figure 6 As shown, the stirring zone of the present invention for friction stir welding has a second embodiment of a stirring head with varying depths. The groove 212 forms a depth change in the circumferential direction of the stirring zone 21 . The depth change structure in the circumferential direction increases the stirring force in the circumferential direction.

[0034] In this embodiment, the protrusion 211 is not higher than the envelope area 22 in the axial direction. Its structure is simple and reliable.

Embodiment 3

[0036] Such as Figure 7 to Figure 9 As shown, the stirring zone of the present invention for friction stir welding has a third embodiment of a stirring head with varying depths. The direction is higher than the envelope area 22. Its structure is simple and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com