Handheld laser welding equipment and safe operation method thereof

A laser welding, hand-held technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems affecting the accuracy and quality of workpiece welding, flexibility and versatility, and the welding torch is heavy, so as to improve the welding quality. Quality and welding efficiency, reduce labor intensity and operation difficulty, improve the effect of safety protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

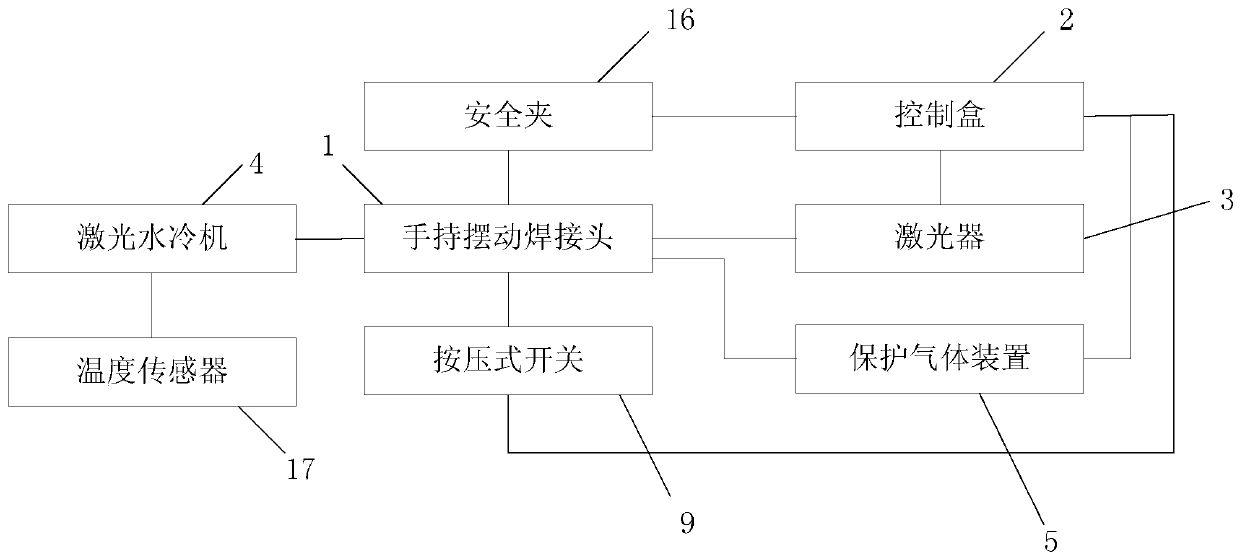

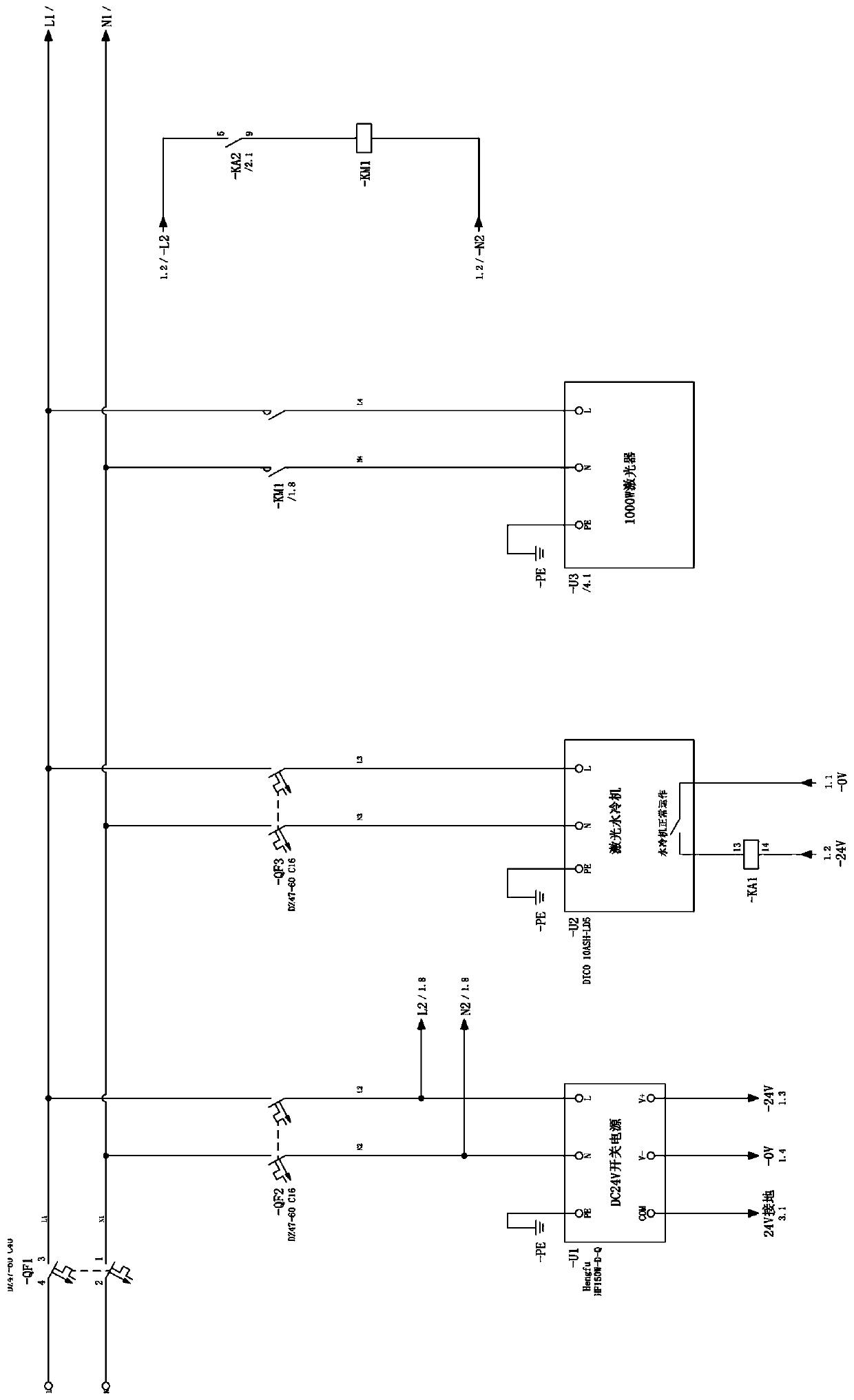

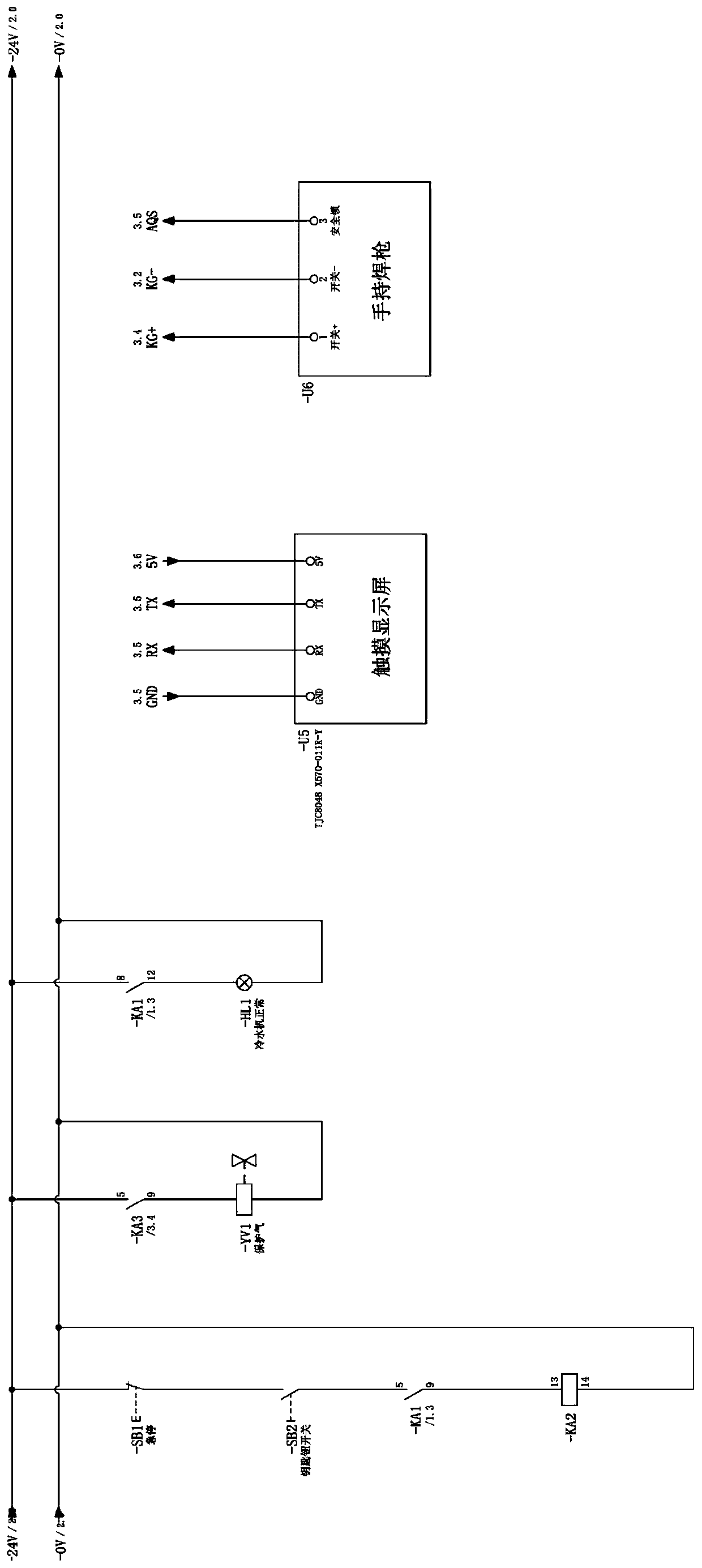

[0047] Such as Figure 1 to Figure 8 As shown, the handheld laser welding equipment of the present invention includes a handheld swing welding head 1, a control box 2, a laser device 3, a laser water cooler 4, a protective gas device 5 and a safety protection control circuit, wherein the laser device 3 communicates with the handheld swing welding head through an optical fiber 1 connection, the laser water cooler 4 is connected with the hand-held swing welding head 1 in the form of a water cooling cycle, that is, it is connected with the water-cooling inlet 6 and the water-cooling outlet 7 to realize water cooling of the hand-held swing welding head 1 . The shielding gas device 5 is connected to the shielding gas inlet 8 of the hand-held swing welding head 1 through the control box 2. The hand-held swing welding head 1 includes a welding head body, a safety clip 16 and a push switch 9 arranged on the welding head body. The control box 2 They are respectively connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com