Molding method for shoes with multi-color shoe soles

A molding method and shoe technology, applied to home appliances, other home appliances, household components, etc., can solve the problems of not being environmentally friendly, easy to open glue, unfavorable wearing and matching, etc., and achieve the effect of not easy to break the bottom and strong binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

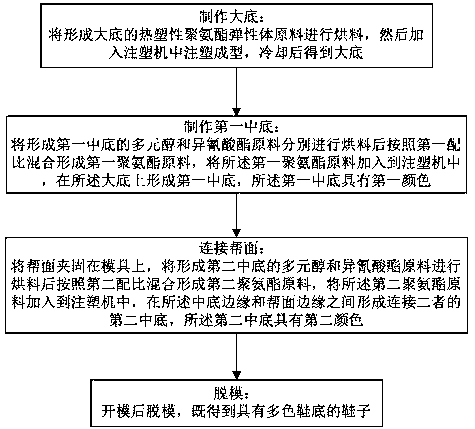

[0024] The invention relates to a molding method of shoes with multi-color soles, the specific flow chart is as follows figure 1 shown.

[0025] First make the outsole. Outsole is the bottom part of the sole that is directly in contact with the ground, so it requires the highest wear resistance of the material. The material used in the outsole in the present invention is TPU, i.e. thermoplastic polyurethane elastomer material. The specific molding process is as follows:

[0026] 1.1 Baking material:

[0027] Prepare TPU raw materials. The TPU raw material is commercially available thermoplastic polyurethane elastomer for foam soles. The use of TPU to make soles has many advantages, such as good wear resistance, flex resistance, shock absorption, anti-skid performance, fatigue resistance, chemical resistance, etc. , very suitable for making the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com