Cam gluing control mechanism applied to paper bag machine

A technology of control mechanism and paper bag machine, which is applied in the direction of papermaking, bag making, paper/cardboard containers, etc. It can solve the problems of difficulty in tearing off, affecting the packaging process of paper bags, and low sealing efficiency of paper bags, so as to simplify the control structure and prevent The effect of production error and precision guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

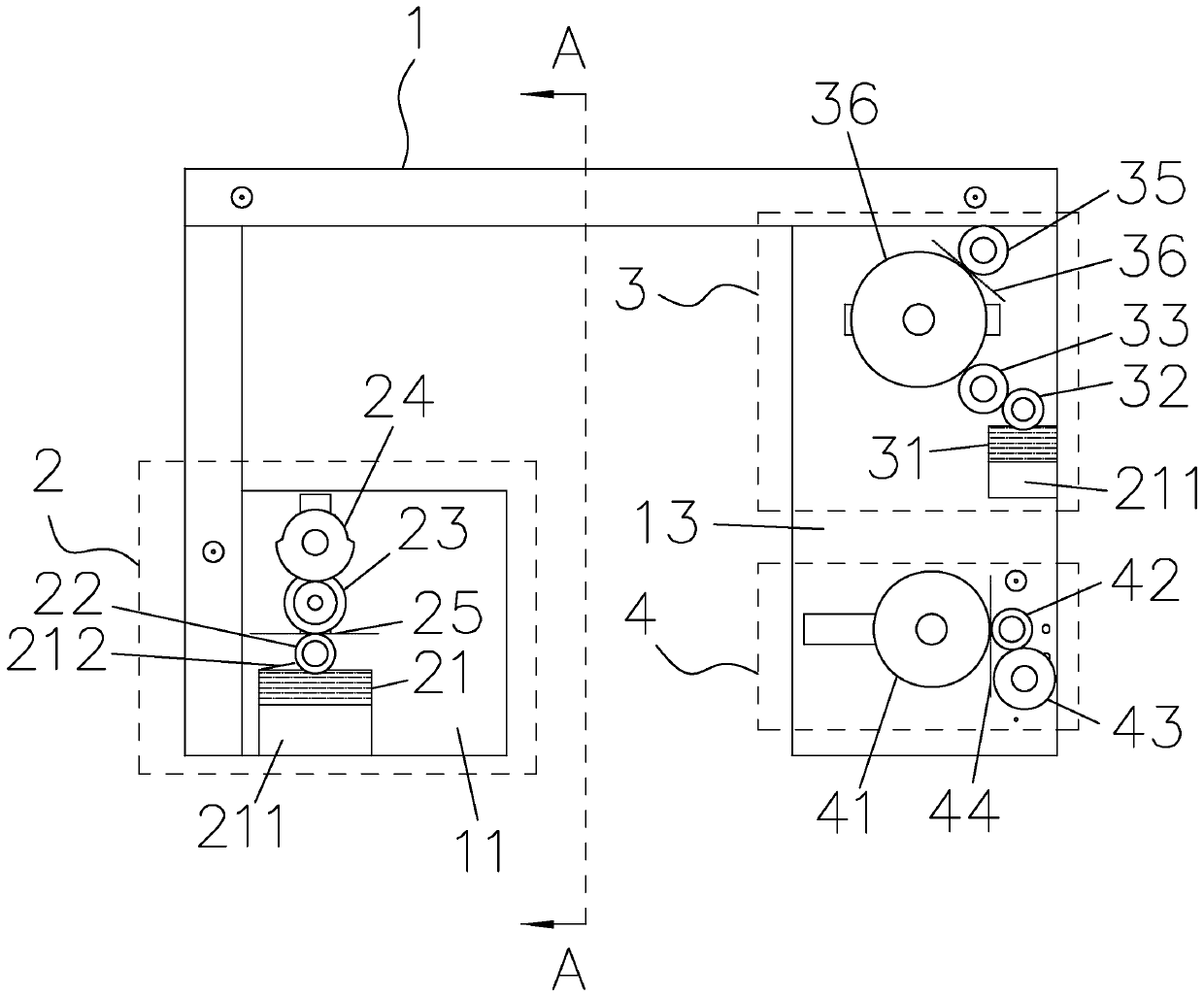

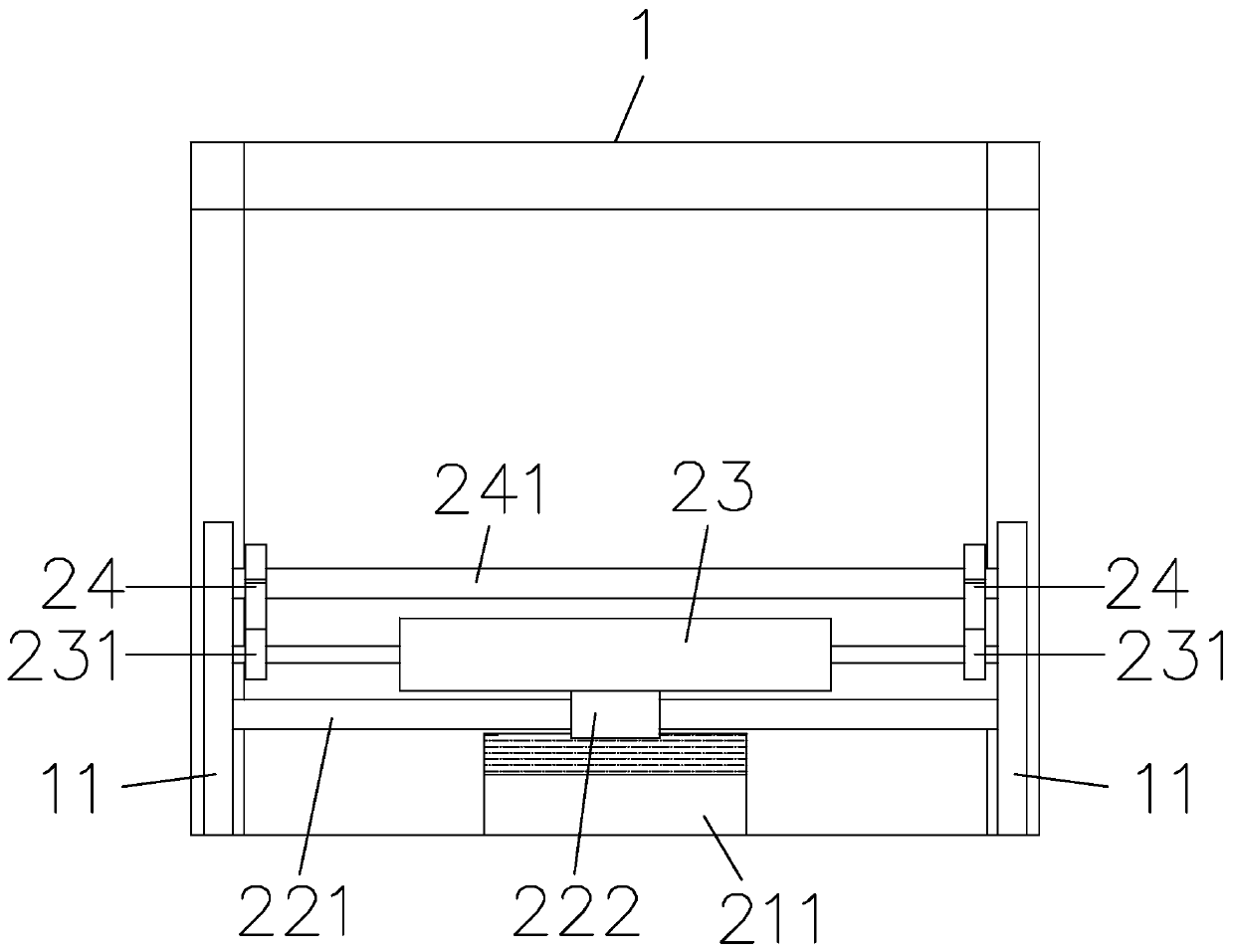

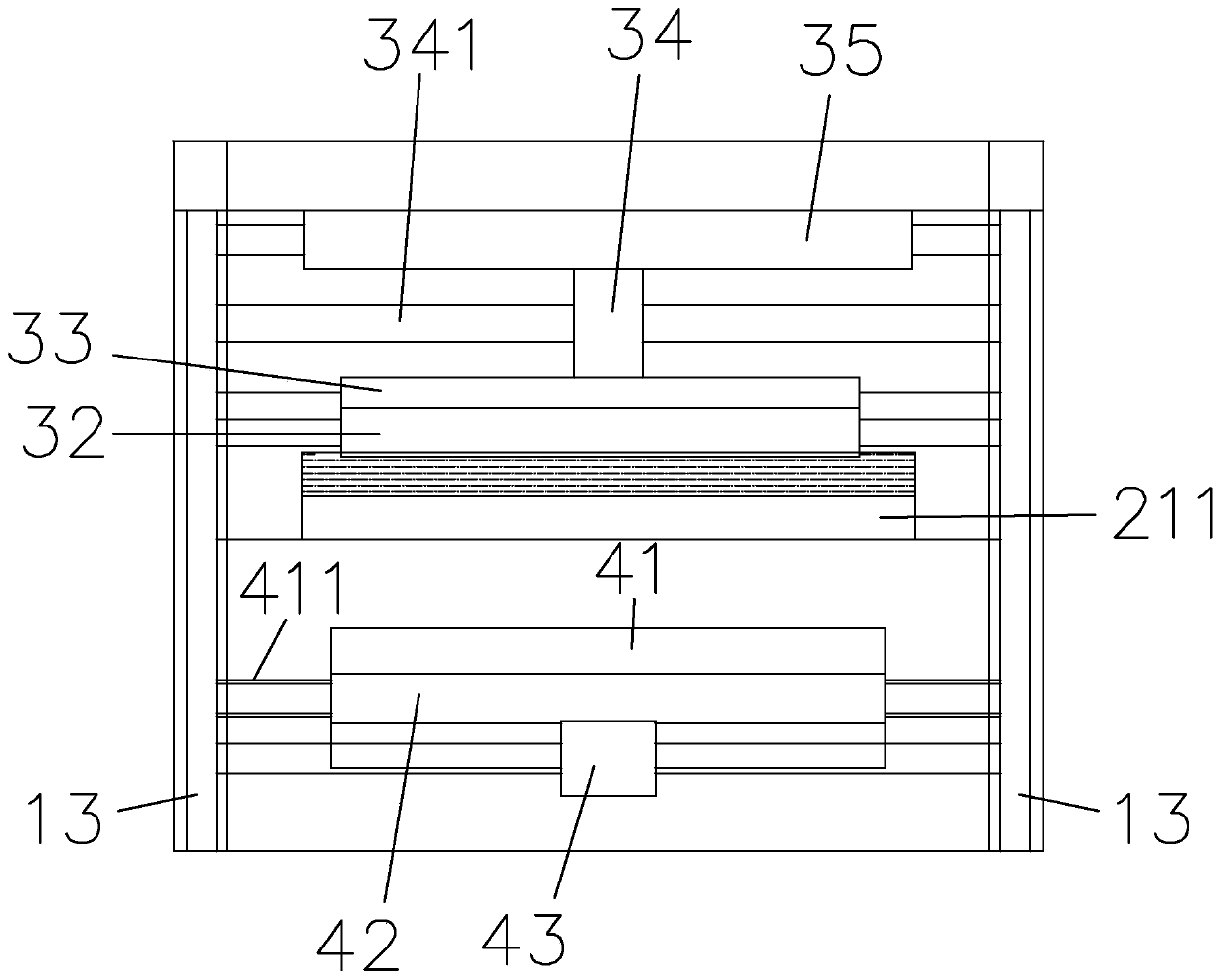

[0026] Such as Figure 1 to Figure 4 As shown, this embodiment discloses a cam gluing control mechanism applied to a paper bag machine, including a frame 1, a gluing mechanism 2 installed at one end of the frame 1, a printing mechanism 3 installed at the other end of the frame 1 and Cutting mechanism 4, described gluing mechanism 2 comprises glue box 21, is arranged on glue roller 22 above glue box 21, is arranged on the glue printing auxiliary roller 23 above glue roller 22, is arranged on the cam above glue roller 24. The rubber printing auxiliary roller 23 moves up and down with the rotation of the cam 24, and alternately separates and sticks with the upper rubber roller 22. Glue channel 25; described printing mechanism 3 comprises ink tank 31, the ink wheel 32 that is arranged on ink tank 31 tops, the screen printing wheel 33 that is arranged on ink wheel 32 tops, the resin plate printing wheel 34 that is arranged on screen printing wheel 33 tops , the guide wheel 35 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com