Hollow divergent type electrochemical reaction chamber

A chemical reaction, divergent technology, applied in chemical instruments and methods, special treatment targets, water/sewage treatment, etc., can solve the problems of poor electromagnetic field distribution uniformity, large scale resistance, uneven water flow distribution, etc. Electromagnetic field uniformity, simple processing, and improved electrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

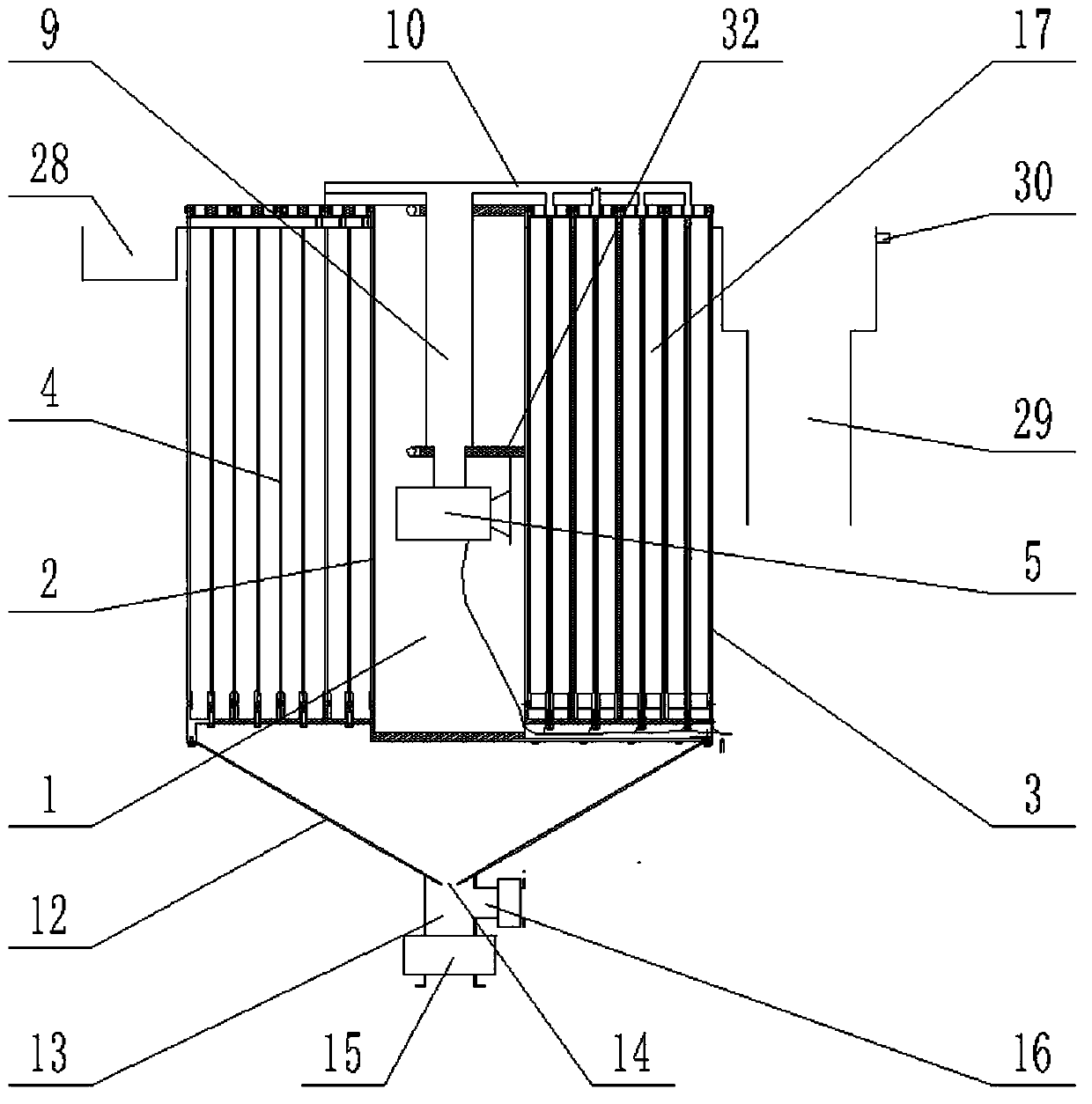

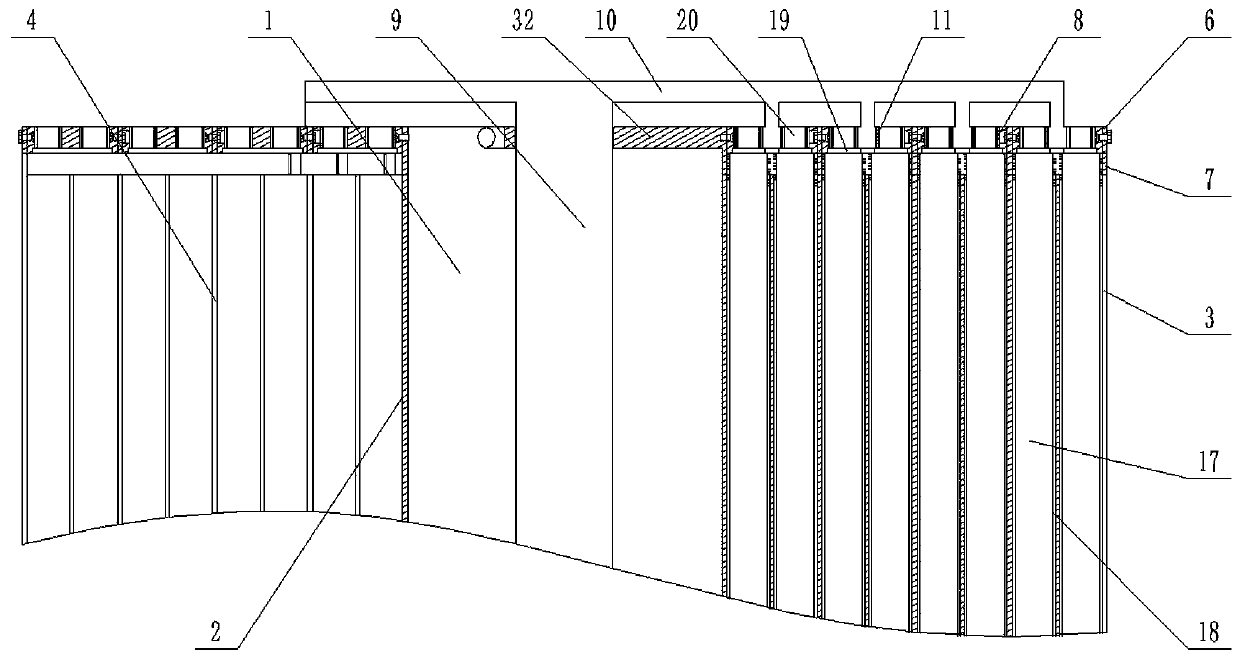

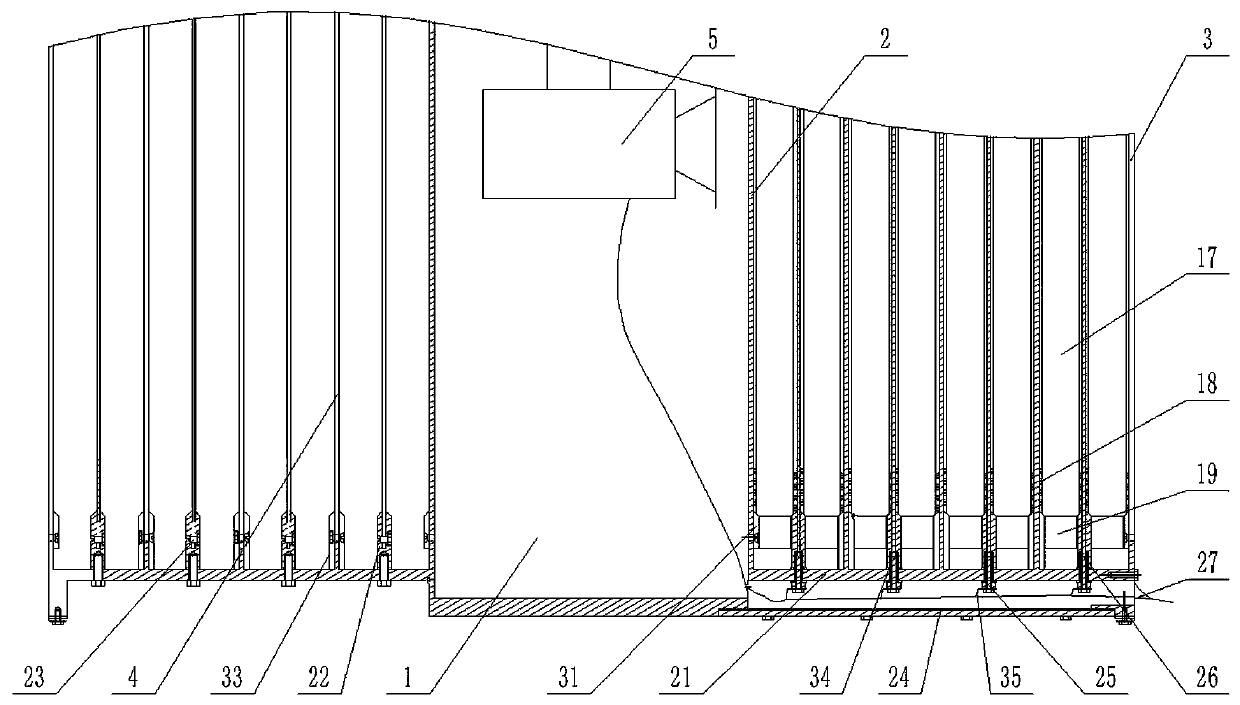

[0023] A hollow divergent electrochemical reaction chamber, including a reaction chamber body, a driving mechanism, a water inlet and outlet mechanism, and a descaling mechanism;

[0024] The reaction chamber body includes a columnar box 1. The cylindrical surface of the columnar box 1 is made of an inner cathode plate 2. The outermost side of the columnar box 1 is provided with a circle of outer cathode plates 3 coaxial with it. The inner cathode plate 2 and Between the outer cathode plates 3, there are several circles of electrode plates 4 coaxial with the two and distributed at intervals, and the electrode plates 4 are composed of cathode plates and anode plates interlacedly distributed, and are connected with the inner cathode plates 2 and the outer cathode plates 3 staggered distribution;

[0025] The drive mechanism includes a geared motor 5 arranged in the columnar box 1 and an annular mounting plate 6 positioned above the cathode plates of the outer cathode plate 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com