Tool high molybdenum martensitic stainless steel with toughness and corrosion resistance superior to toughness and corrosion resistance of 9Cr18MoV and method

A technology of martensitic stainless steel, 9cr18mov, applied in the field of high-molybdenum martensitic stainless steel and methods for cutting tools whose toughness and corrosion resistance are superior to 9Cr18MoV, which can solve the problems of difficult processing, reduced plasticity and toughness, and increased thermal deformation resistance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

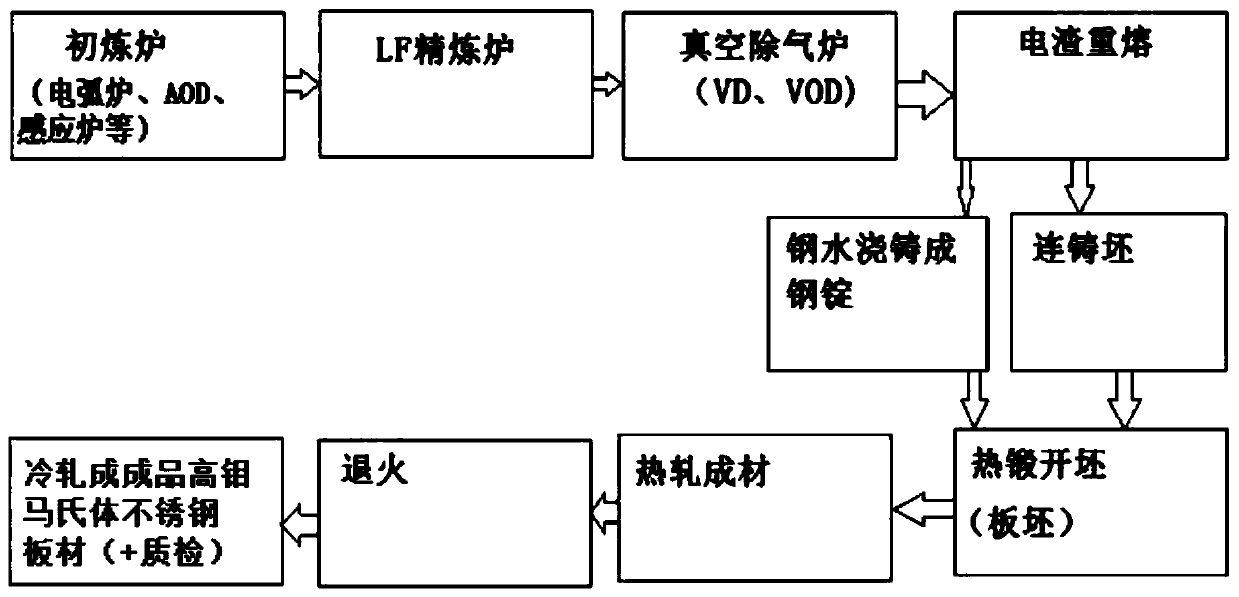

[0022] Below in conjunction with embodiment and accompanying drawing ( figure 1 ) to illustrate the present invention.

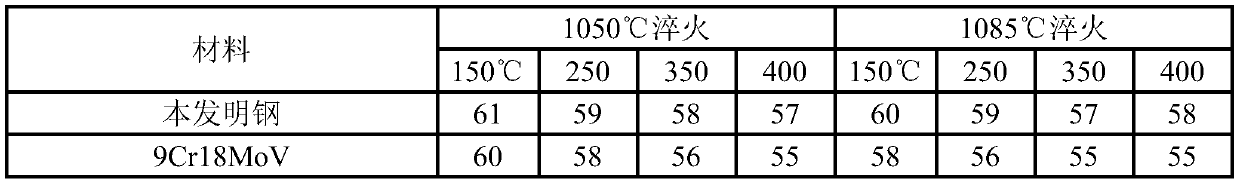

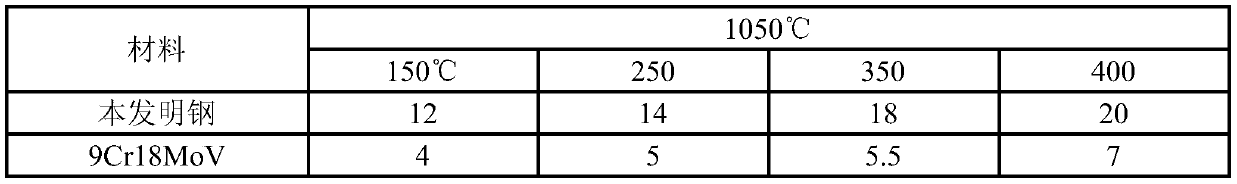

[0023] The purpose of the present invention is to provide a martensitic stainless steel for knives with high hardness, toughness and corrosion resistance, which is used to make high-end knives with high sharpness and high durability. Based on 9Cr18MoMV high-end steel, optimize the composition and content of alloying elements to improve material performance: (1) reduce C and increase Mo, optimize carbide content and size, and improve plastic toughness and corrosion resistance. (2) Increase the content of Mn, expand the austenite phase region, improve the stability of austenite, increase the content of residual austenite, and improve the plasticity and toughness; (3) reduce the content of impurity elements, especially the content of S, and reduce or eliminate MnS inclusions.

[0024] High-molybdenum martensitic stainless steel for cutting tools with toughnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com