500MPa hot-rolled refractory steel bar and manufacturing method thereof

A manufacturing method and steel bar technology, which is applied in the field of building steel bar materials, can solve problems such as lack, and achieve the effects of low manufacturing cost, reasonable component design, and avoiding abnormal organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

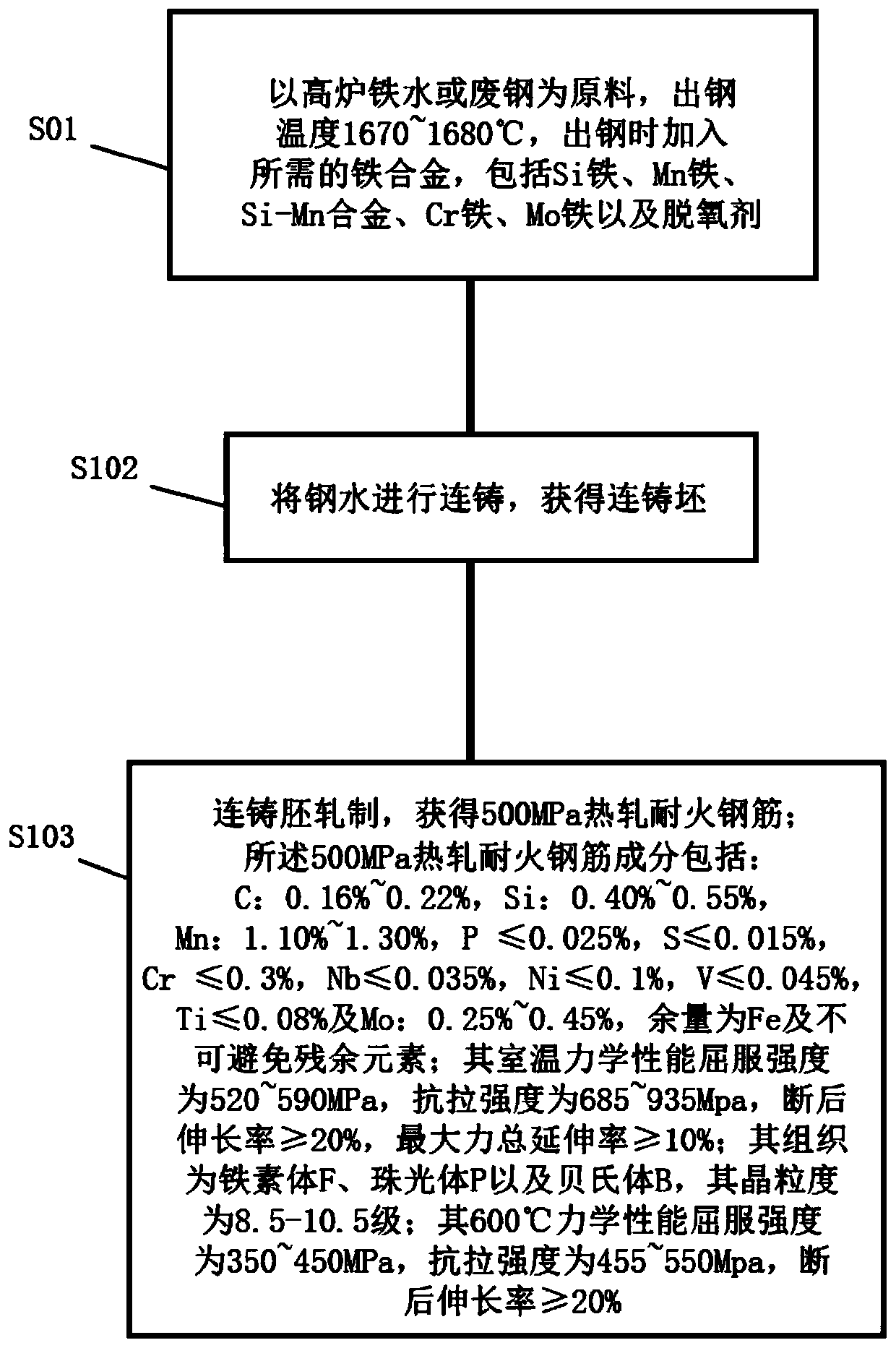

Method used

Image

Examples

Embodiment Construction

[0065] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

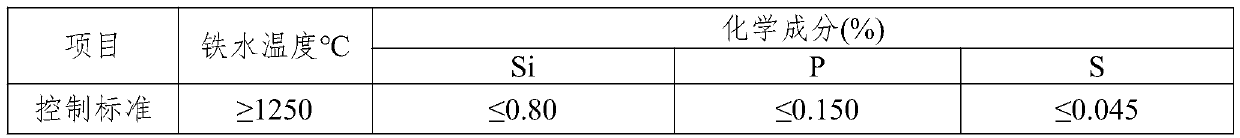

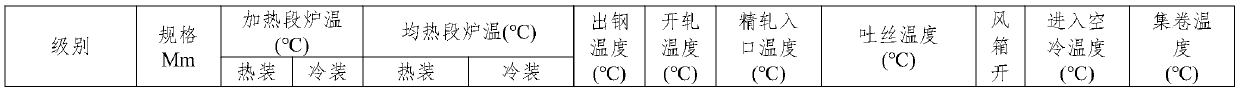

[0066] 1. A 500MPa hot-rolled refractory steel bar, characterized in that its composition includes: C: 0.16% to 0.22%, Si: 0.40% to 0.55%, Mn: 1.10% to 1.30%, P≤0.025%, S≤0.015 %, Cr ≤ 0.3%, Nb ≤ 0.035%, Ni ≤ 0.1%, V ≤ 0.045%, Ti ≤ 0.08% and Mo: 0.25% ~ 0.45%, the balance is Fe and unavoidable residual elements; its mechanical properties at room temperature yield The strength is 520-590MPa, the tensile strength is 685-935Mpa, the elongation after fracture is ≥20%, and the total elongation of the maximum force is ≥10%; its structure is ferrite F, pearlite P and bainite B, and its crystal The particle size is 8.5-10.5; its mechanical properties at 600°C yield strength is 350-450MPa, tensile strength is 455-550Mpa, and elongation af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com