Steel wire galvanization method and galvanization device used in steel wire galvanization method

A technology of steel wire galvanizing and galvanizing bath, which is applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of inability to dissolve uniformly, poor galvanizing effect, low density of rare earth, etc., and achieve structural design Simple and reasonable, improving effect and efficiency, high-quality finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

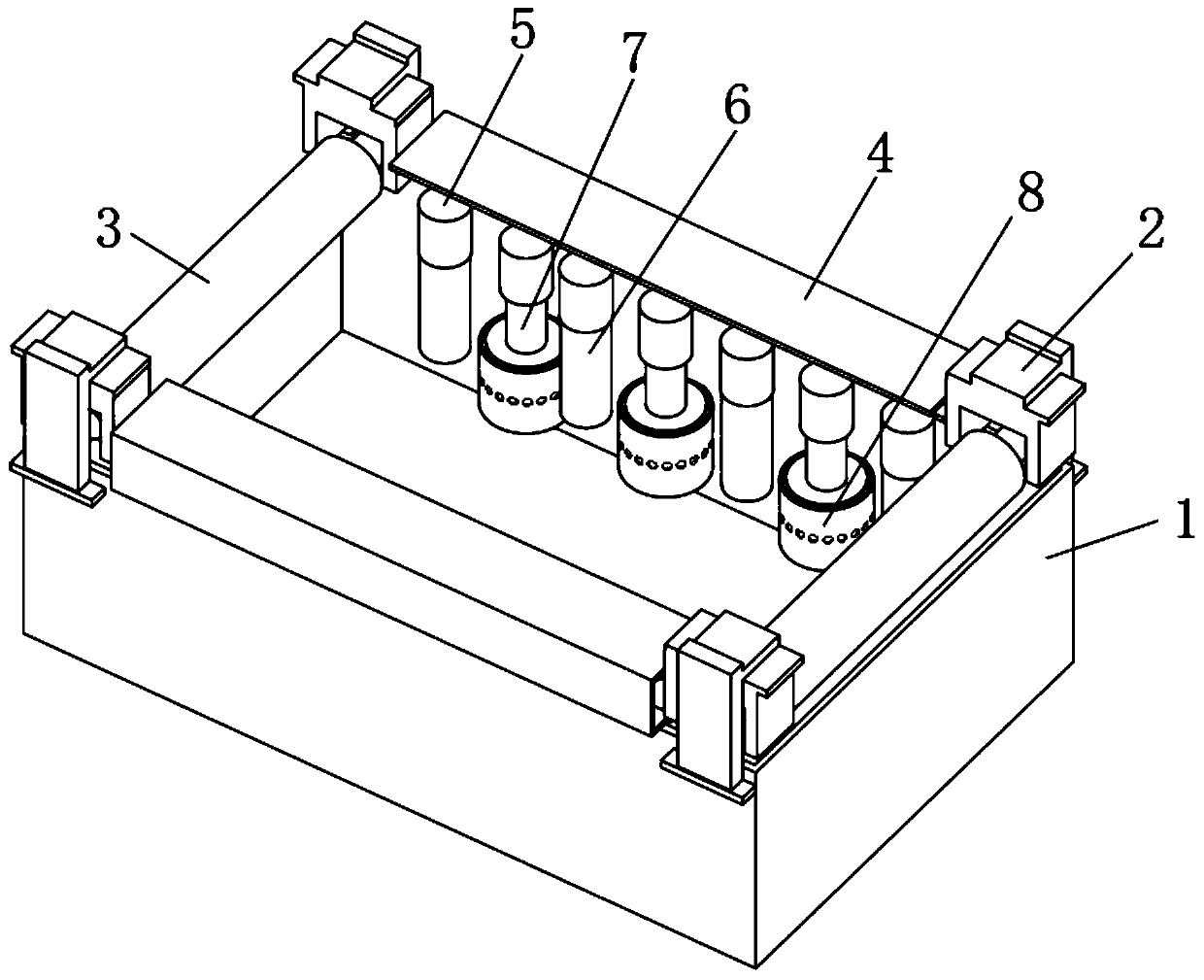

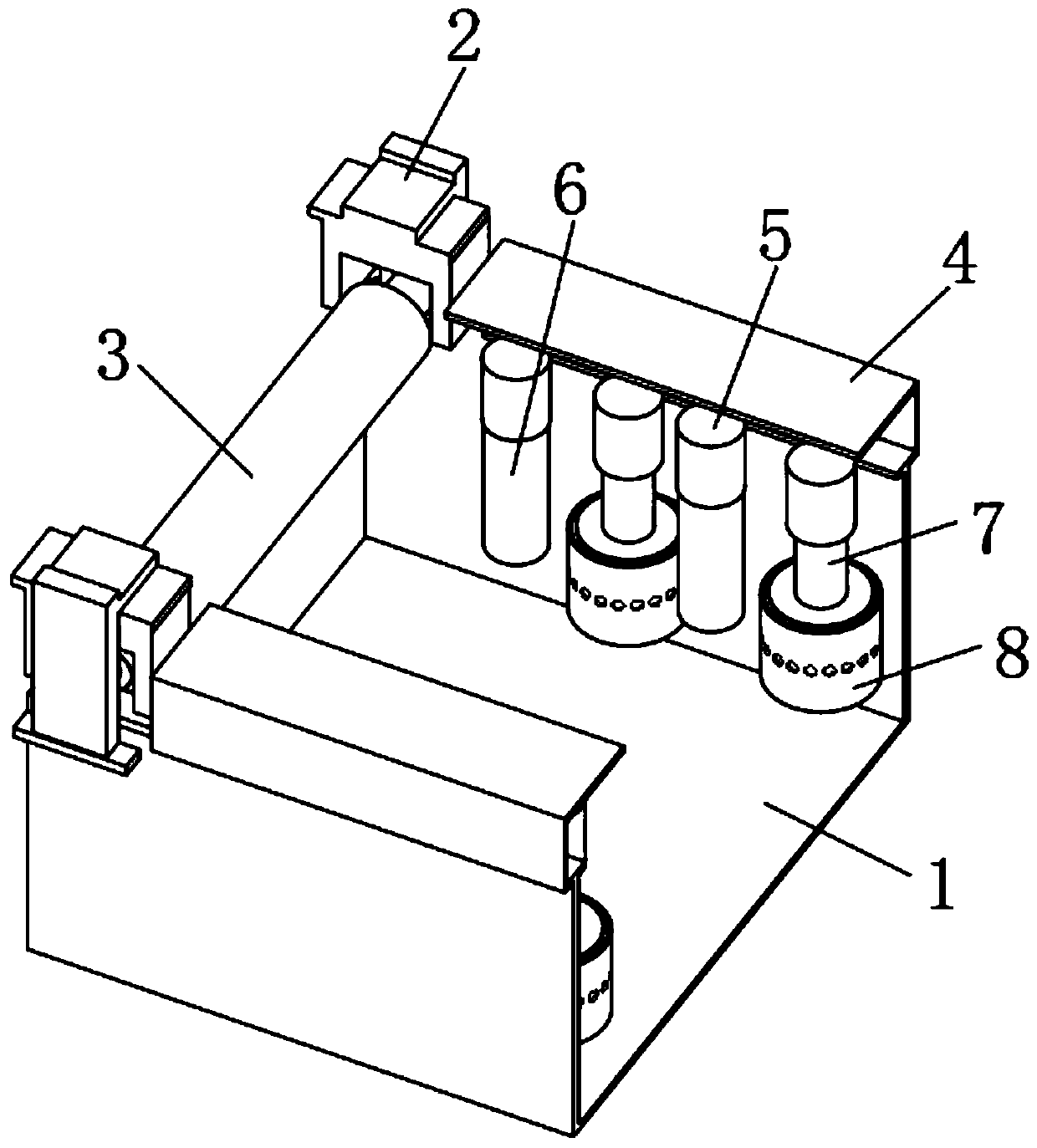

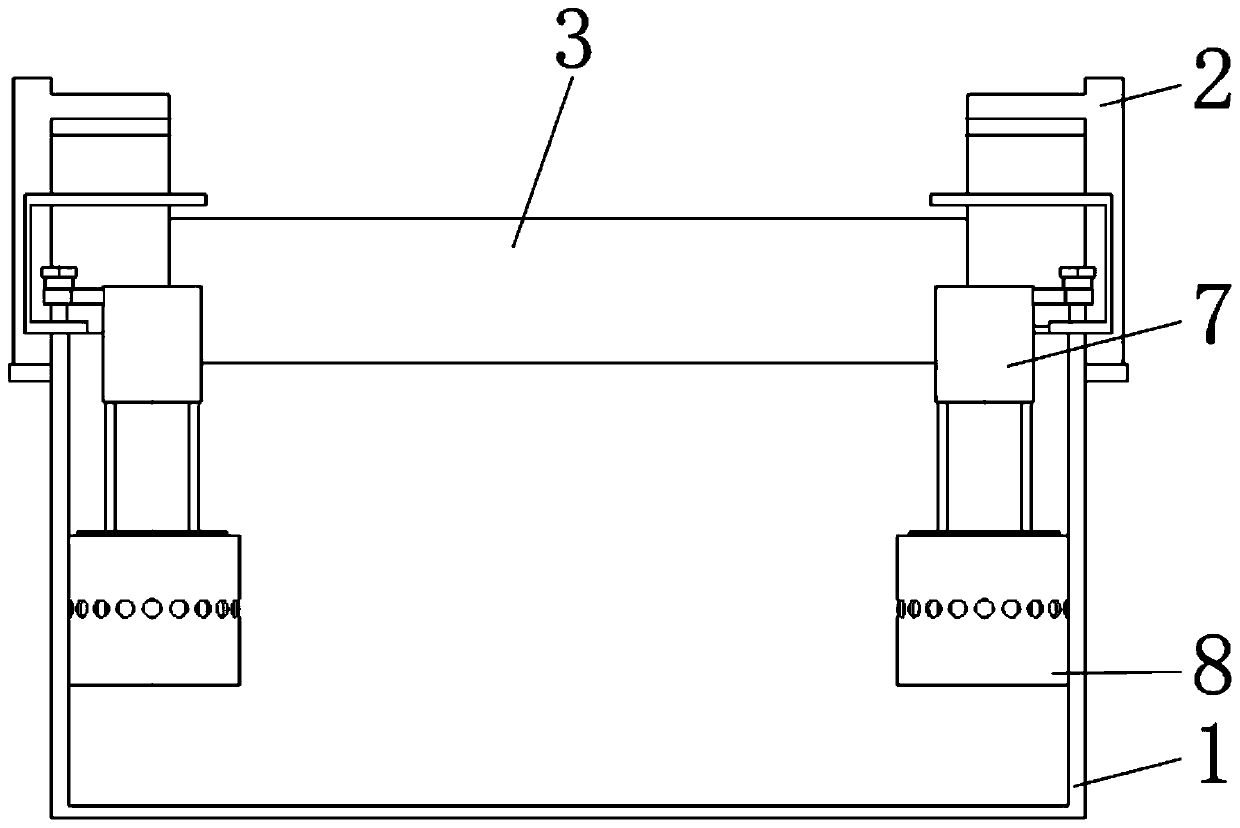

Image

Examples

Embodiment 1

[0049] A method for using a steel wire galvanizing device includes the following steps:

[0050] The first step: pre-plating treatment: remove the lubricating film or oxide scale on the surface of the steel wire and clean it;

[0051] The second step: assisting plating treatment, the steel wire enters the assisting bath, so that the surface of the steel wire is covered with a layer of assisting agent, which is isolated from the air, so that the steel wire is no longer oxidized;

[0052] The third step: galvanizing treatment: set a layer of covering agent on the surface of the zinc liquid to prevent the oxidation of the zinc liquid, control the galvanizing temperature at 450℃, and put the rare earth into the galvanizing bath 1 through the rare earth adding device , When putting in the rare earth, keep the height of the rare earth container 8 from the galvanizing bath 1 15 cm, put 10 kg of rare earth each time, put the rare earth again after 5 days, and use the rare earth adding device...

Embodiment 2

[0055] A method for using a steel wire galvanizing device includes the following steps:

[0056] The first step: pre-plating treatment: remove the lubricating film or oxide scale on the surface of the steel wire and clean it;

[0057] The second step: assisting plating treatment, the steel wire enters the assisting bath, so that the surface of the steel wire is covered with a layer of assisting agent, which is isolated from the air so that the steel wire is no longer oxidized;

[0058] The third step: galvanizing treatment: set a layer of covering agent on the surface of the zinc liquid to prevent the oxidation of the zinc liquid, control the galvanizing temperature at 465℃, and put the rare earth into the galvanizing bath 1 through the rare earth adding device , When putting in the rare earth, keep the height of the rare earth container 8 from the galvanizing pool 1 at 25 cm, put 15 kg of rare earth each time, put the rare earth again after 5 days, and use the rare earth addition de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com