Dual-density triangular bottom plate for horizontal knitting machine

A flat knitting machine, double density technology, used in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of electromagnetic heating, electromagnetic failure spring machinery, fatigue, etc., to avoid failure losses and enrich the variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

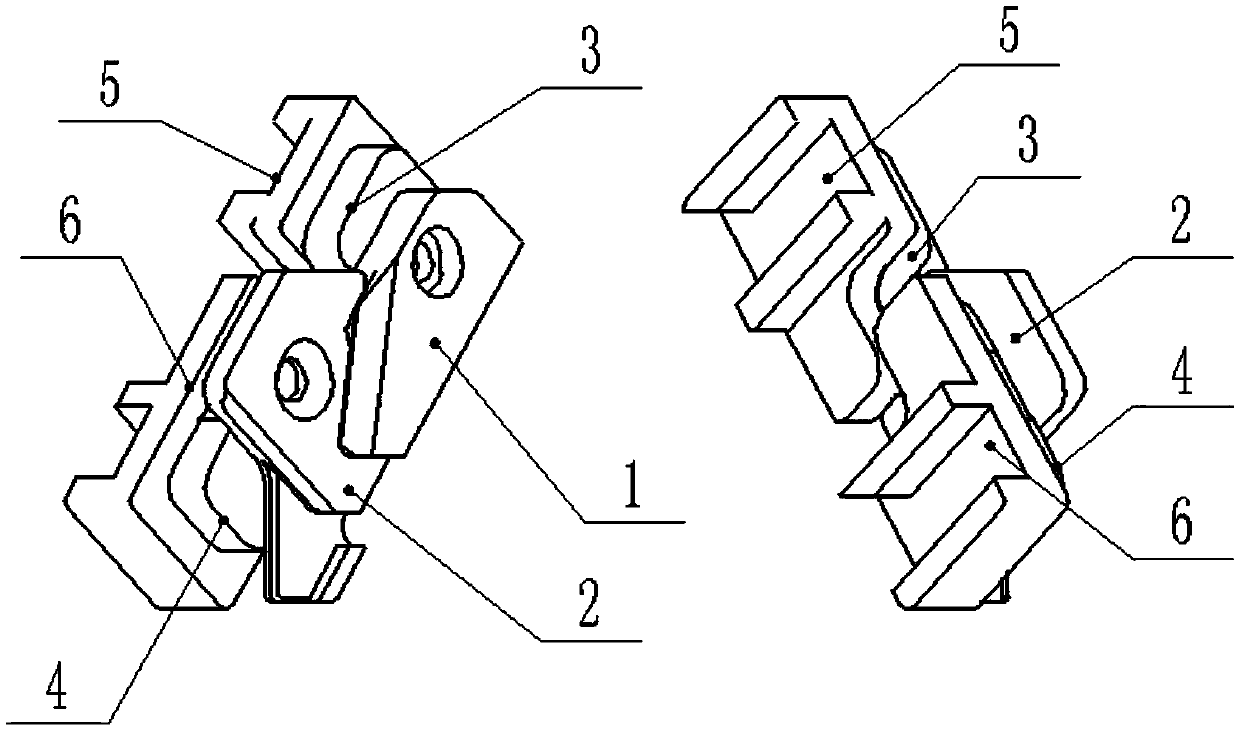

[0035] Double Density Triangular Mechanism

[0036] Such as figure 1 , 2As shown in , 3, a double-density flat knitting machine triangular base plate is provided with a double-density triangular assembly on the triangular base plate, and the double-density triangular assembly includes upper and lower density triangles 1 for implementing the first set of density arranged in upper and lower positions and used In the implementation of the second set of density lower density triangle 2, the upper and lower density triangles are respectively fixed on the density slider, and the upper and lower density sliders 3 and 4 are respectively connected to the density slider baffle plate (5. Upper density slider baffle plate, 6. lower density slider baffle plate), the upper and lower density sliders in the shape of yin and yang fish are arranged in the chute on the triangular bottom plate.

[0037] Dual Density Control Mechanism

[0038] The double-density control assembly is clamped in t...

Embodiment 2

[0041] Such as Figure 6 As shown, the triangular bottom plate of the present invention includes a triangular support plate 70 and a needle selector support plate 72 .

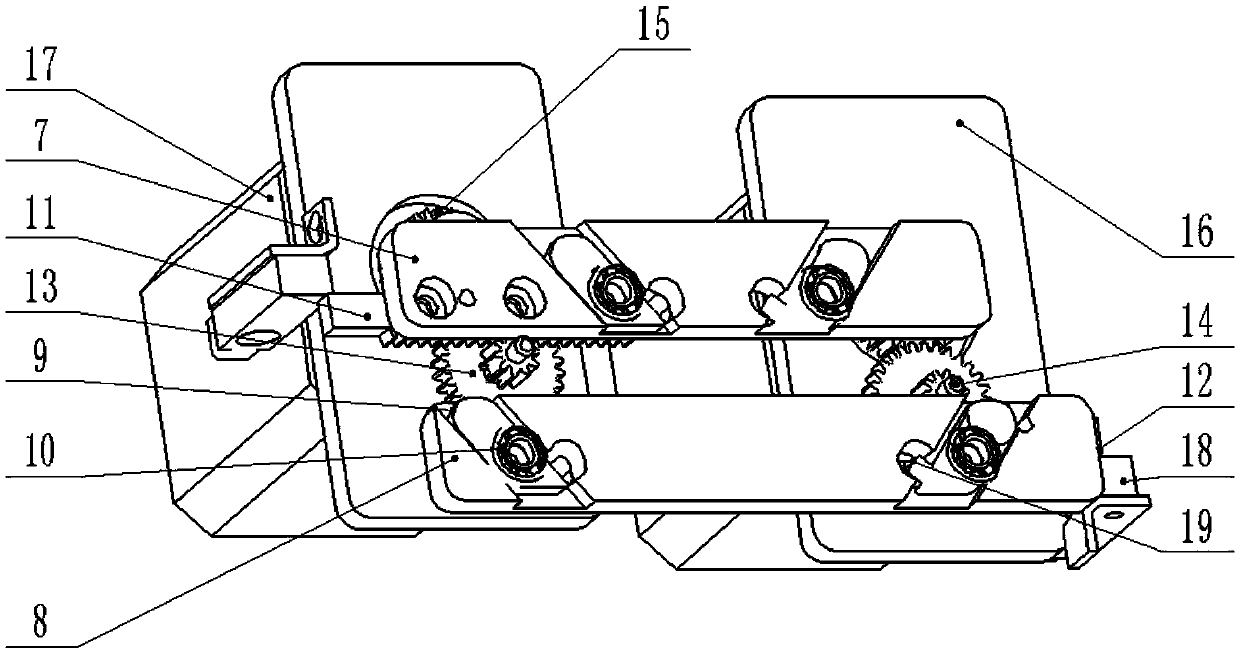

[0042] The upper side of the triangular support plate is provided with an upper needle bell control triangle group, and the upper needle bell control group includes left, middle and right needle protection triangles 50, 51, 52, bridge triangle 53 and transfer needle transfer triangle 34.

[0043] The lower needle bell control triangle group is provided at the corresponding position on the lower side of the triangular support plate. The lower needle bell control triangle group includes the butterfly mountain triangle 60, the weaving cam 33, the left and right double-density triangle components, and the left, middle and right needle clearing triangles 57, 58, 59. The double-density cam assembly is set on both sides of the knitting cam, and the transfer cam is set above the position corresponding to the knitting ...

Embodiment 3

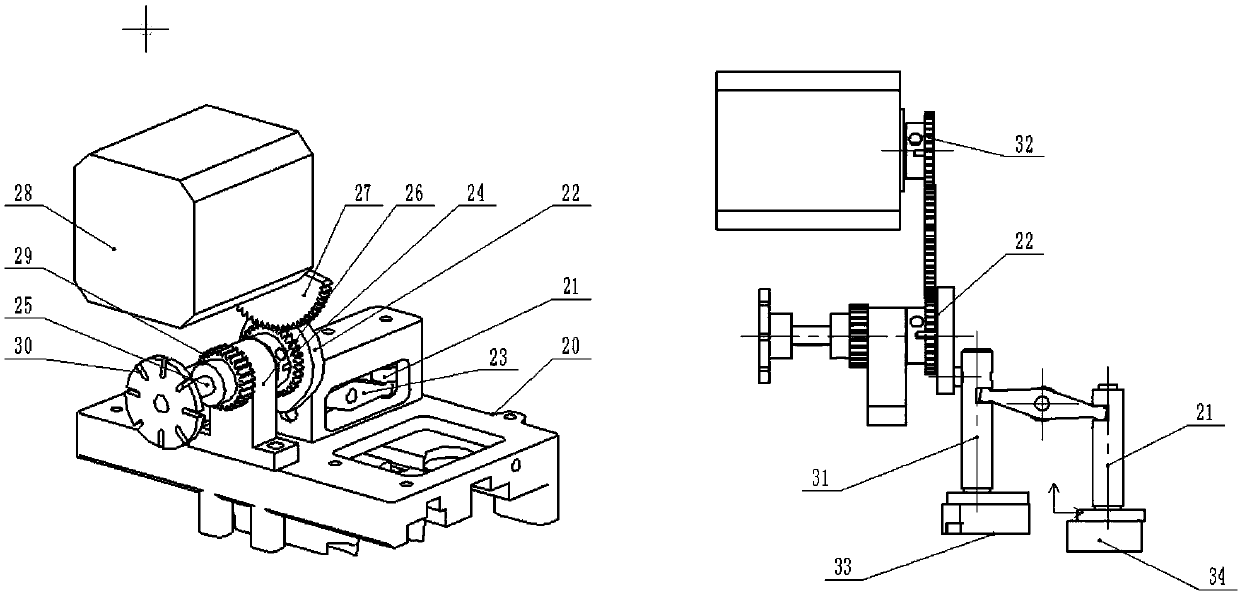

[0046] Integrated Control Mechanism

[0047] Such as image 3 , 4 As shown, the knitting cam and the transfer cam are connected to the knitting cam guide seat 31 and the transfer cam guide seat 21 of the integrated control assembly; the knitting cam guide seat and the transfer cam guide seat are respectively installed on the integrated fixing seat In the guide hole, and connected by the transfer seesaw 23 to realize the relative position linkage.

[0048] The braiding triangle guide rod links to each other with the transfer cam 22, and the transfer cam, the control motor gear 32, the pressing plate control gear 29 and the code disc 30 are connected successively by the control shaft, and are connected to the integrated fixed seat 20 by the cam seat 26, controlled by the control motor 28 drives the gear to rotate, and there are position slots corresponding to 7 positions on the code disc, which cooperate with the slot-type photocoupler switch 39 and the zero position sensor 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com