Efficient dyeing equipment for textile cloth

A kind of dyeing equipment and high-efficiency technology, which is applied in the direction of processing textile material equipment configuration, textiles and papermaking, textile processing machine accessories, etc., can solve the problems of general stirring effect, tearing and damage of cloth, and slow dyeing speed, so as to improve the dyeing effect, The effect of preventing cloth damage and avoiding the use of stirring rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

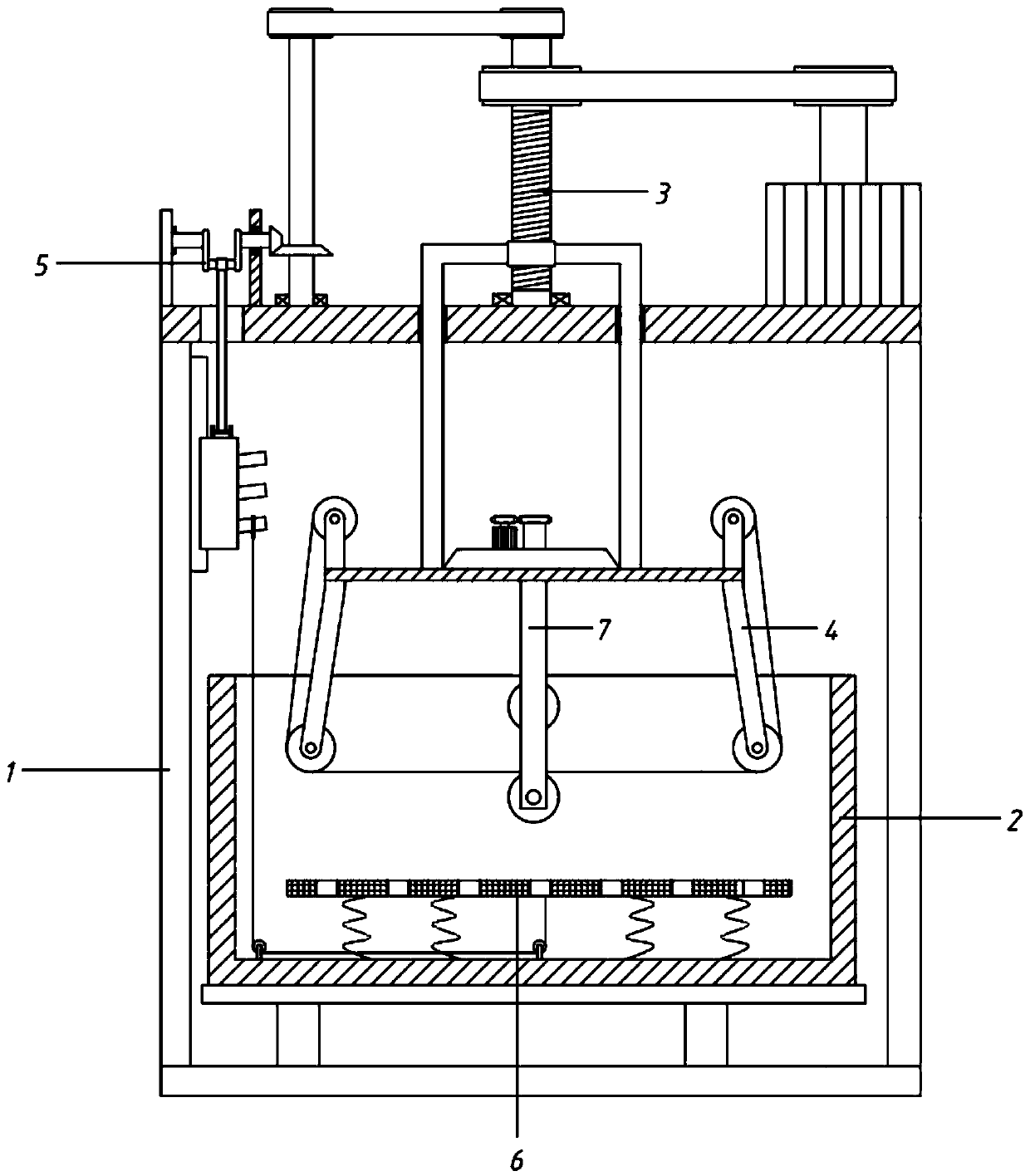

[0059] A high-efficiency dyeing equipment for textile cloth, including a frame 1, a dyeing box 2, a lifting component 3, a dyeing component 4 and a turbulent flow component 6;

[0060] The frame 1 includes a bottom plate 101, a vertical plate 102 and a top plate 103, the vertical plate 102 is fixedly connected to the left and right ends of the bottom plate 101, and the top of the vertical plate 102 is connected by the top plate 103; the dyeing box 2 is arranged above the bottom plate 101; Component 6; the lifting component 3 is arranged on the top plate 103, and the lifting component 3 passes through the top plate 103 downwards and is connected with the dyeing component 4.

Embodiment 2

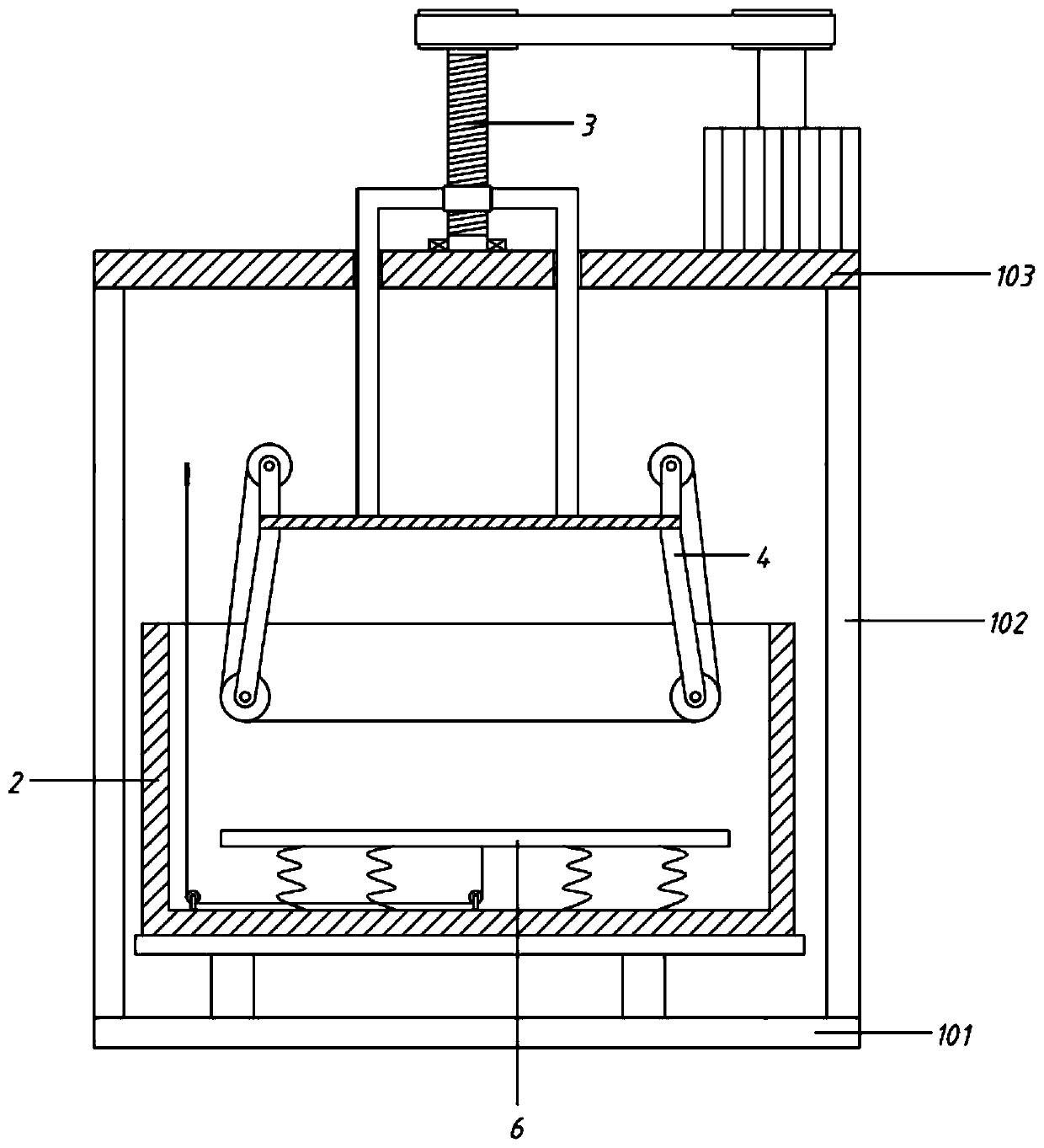

[0062] A high-efficiency dyeing equipment for textile cloth, including a frame 1, a dyeing box 2, a lifting component 3, a dyeing component 4 and a turbulent flow component 6;

[0063] The frame 1 includes a bottom plate 101, a vertical plate 102 and a top plate 103, the vertical plate 102 is fixedly connected to the left and right ends of the bottom plate 101, and the top of the vertical plate 102 is connected by the top plate 103; the dyeing box 2 is arranged above the bottom plate 101; Component 6; the lifting component 3 is arranged on the top plate 103, and the lifting component 3 passes through the top plate 103 downwards and is connected with the dyeing component 4.

[0064] Wherein, the dyeing box 2 includes a box body 203, a placement plate 202 and a pole 201, the placement plate 202 is fixedly connected above the base 101 by the pole 201, the box body 203 is placed on the placement plate 202, and the top of the box body 203 is provided with an opening. It is convenie...

Embodiment 3

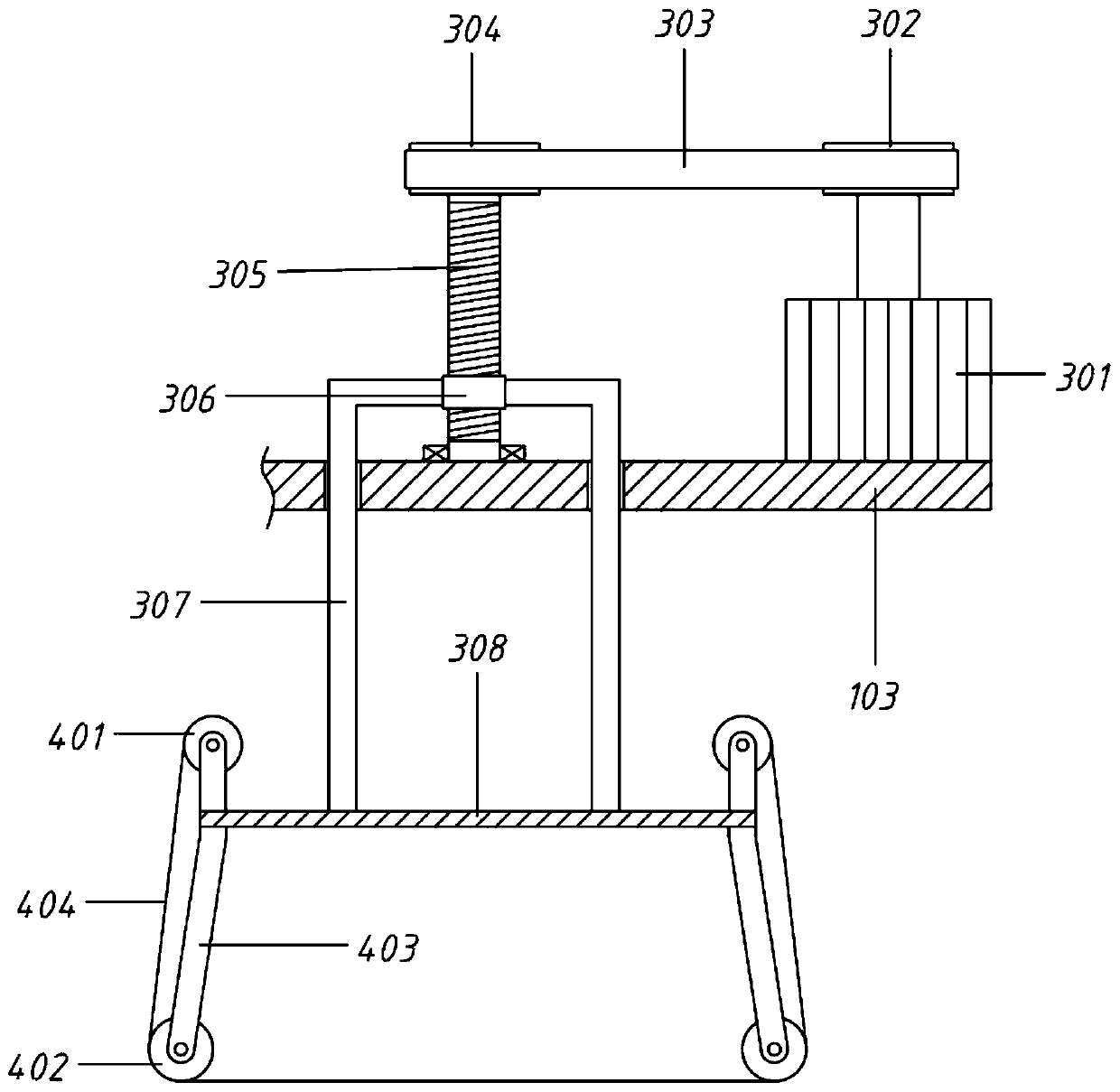

[0076] On the basis of embodiment 2,

[0077] The retractable structure 401 includes the retractable roller 4011, the mounting end 4012, the mounting base 4013, the first type of support plate 4014, the second servo motor 4015, the moving block 4016, the first slide rail 4017, the second type of support plate 4018, and the second screw 4019 and handle 4020;

[0078] The first-class support plates 4014 are symmetrically arranged front and back, and the bottom of one of the first-class support plates 4014 is connected with a moving block 4016, and the bottom of the moving block 4016 is slidably connected to a No. 1 slide rail 4017, and the No. The two ends of the rail 4017 are provided with a class of support plates 4018, and a No. 2 screw 4019 is rotated between the Class 4 support plates 4018. The No. 2 screw 4019 passes through and is screwed to the moving block 4016. One end of the No. 2 screw 4019 is externally connected with a handle 4020; The opposite side of the class s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com