Bolt device, damper, mounting mode of damper and drum washing machine

A damper and latch technology, applied in the field of washing machines, can solve problems such as inability to eliminate motion wear and abnormal noise, and inability to meet the rigidity of latches, and achieve the effects of meeting rigidity requirements, improving reliability, and improving simplicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: a kind of latch device.

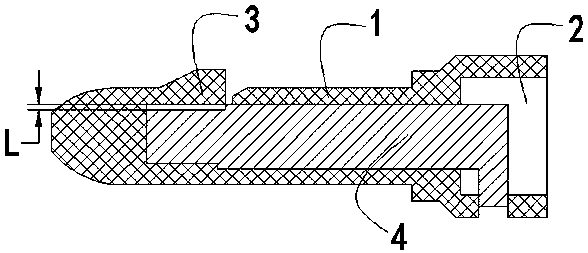

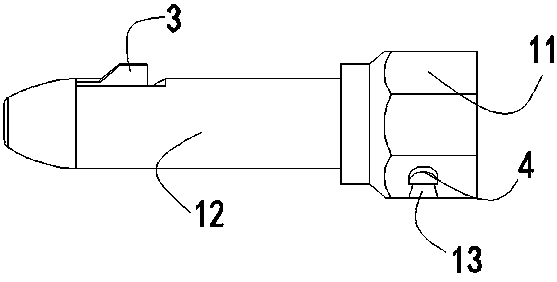

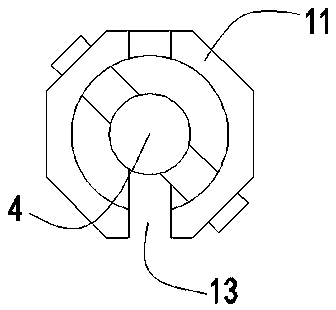

[0034] Such as Figure 1-3 As shown, the embodiment of the present invention provides a bolt device, which is applied to install a fixed damper, and includes a bolt connector 1 , a cavity 2 is provided inside the bolt connector 1 , and the outer peripheral wall of the bolt connector 1 is fixed with a The limit clamping part 3 of the installation position of the bolt connector 1 is detachably connected with the bolt fixing part 4 for improving the rigidity of the bolt connector 1 inside the bolt connector 1. The assembly form of the surplus combination not only meets the rigidity requirements of the bolt device when the bolt is inserted, but also improves the simplicity of installation and removal. The situation of shifting and loosening improves the reliability of assembly.

[0035] Such as figure 1 As shown, in the preferred embodiment, there is a certain gap between the lower end of the limit clip 3 and the outer diameter of ...

Embodiment 2

[0040] Embodiment 2: a damper.

[0041] Such as Figure 6-7 As shown, this embodiment provides a damper, including a damper body 5, a damper base 6 and the latch device in Embodiment 1, the damper body 5 and the damper base 6 are fixedly connected by a latch device, and the latch The device is detachably fixed at the junction of the damper body 5 and the damper.

[0042] Such as Figure 6-7 As shown, in the preferred embodiment, the limit distance of the latch device is A, and the width of the damper base 6 is B, wherein A and B satisfy the following relationship: A=B; further, the damper body 5 and the damper base There is a certain gap between the side walls of 6, and the length of the gap is D.

Embodiment 3

[0043] Embodiment 3: An installation method of a damper.

[0044] Such as Figure 6-7 As shown, this embodiment provides a damper installation method, including the following steps:

[0045] (1) Install the pin connector 1 and the damper on the damper base 6 first;

[0046] (2) Install the pin fixing part 4 in the pin connecting part 1;

[0047] (3) Lock the bolt fixing part 4 on the bolt connecting part 1 by means of reverse rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com