Deep back filling soil infilled wall foundation construction method

A technology for foundation construction and infill wall, which is applied in basic structure engineering, filling, sheet pile wall, etc. It can solve the problems of cracking of cushion layer and infill wall, thick backfill depth, affecting project quality and safety, etc., and achieve maintenance costs. The effect of reducing, high flexural strength, ensuring structural quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

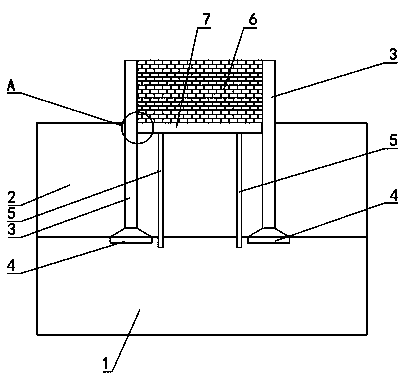

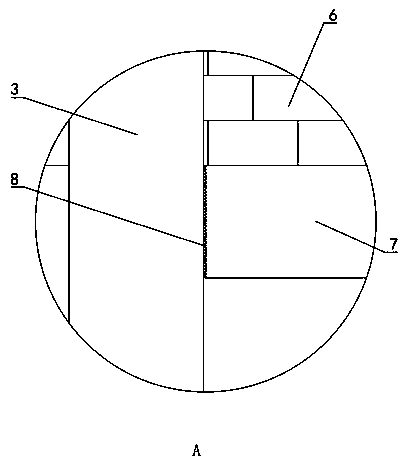

[0031] Figure 1~2 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~2 The present invention will be further described.

[0032] A deep backfill soil filling wall foundation structure, including a rock layer 1, a backfill soil layer 2, and a filling wall 6 arranged in sequence from bottom to top, and also includes ground beams 7, support columns and structural columns 3, and the two ends of the filling wall 6 are A structural column 3 connected to it is provided, the lower end of the structural column 3 is supported on the rock layer 1, the ground beam 7 is set on the lower side of the filling wall 6, the ground beam 7 is independently set up with the structural column 3, and the lower end of the supporting column is connected with the rock layer 1, The upper end is connected with the ground beam 7 . The ground beam 7 and the structural column 3 of this deep backfill soil-filled wall foundation structure are set independently, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com