Novel landslip-resistant shed tunnel and construction method

A shed cave, a new type of technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problem that the shed cave does not have the ability to resist lateral slippage, so as to increase the ability to resist lateral deformation, improve stability, and improve The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

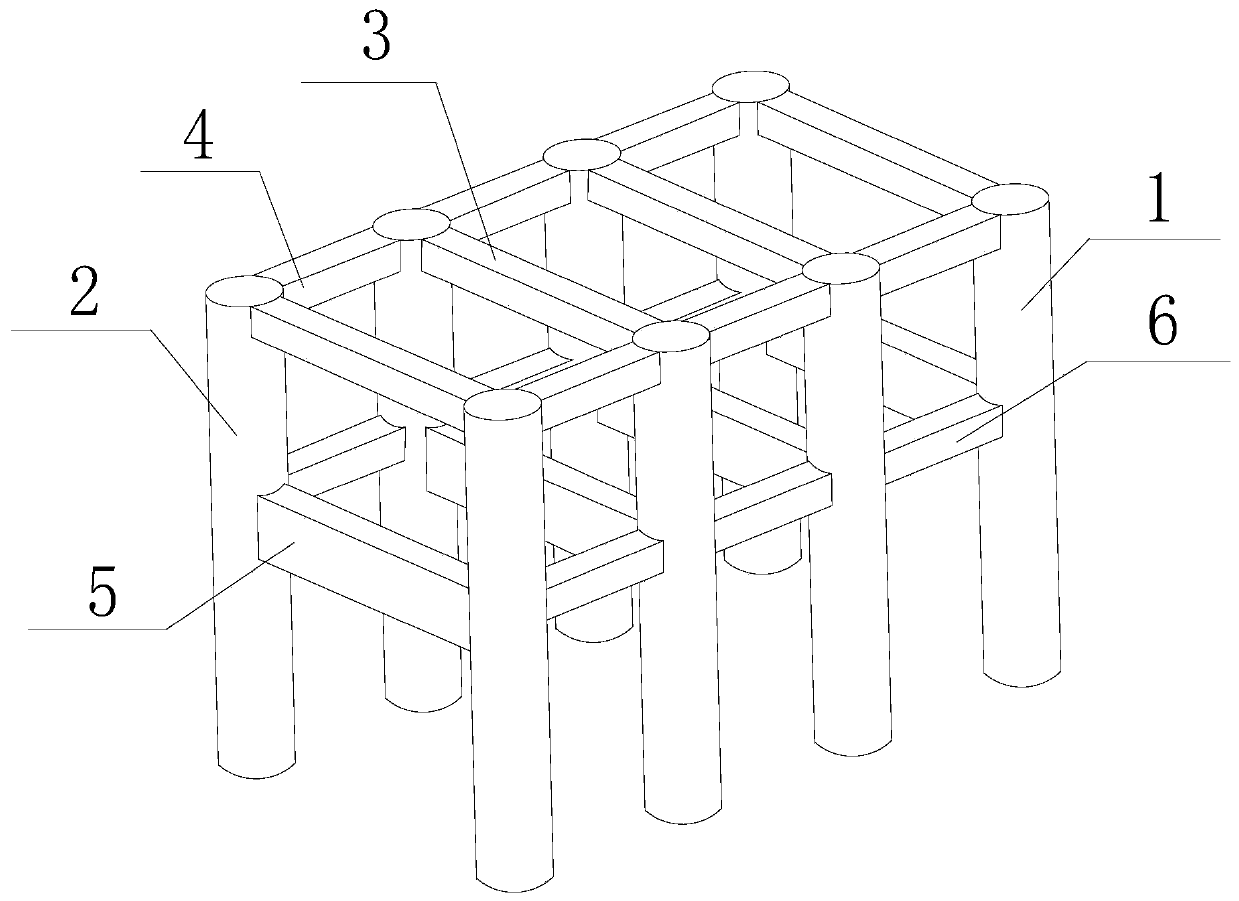

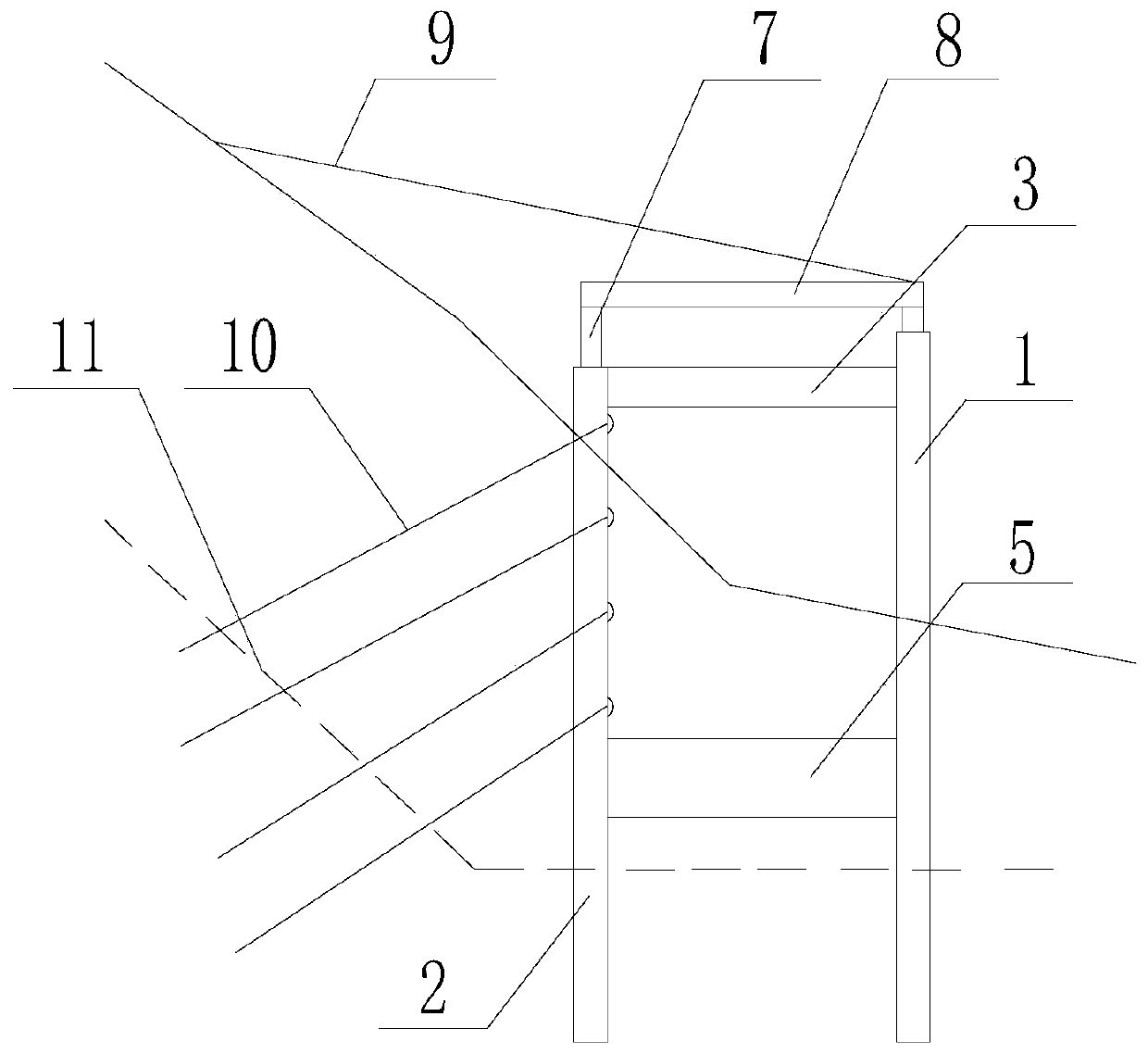

[0042] Such as figure 1 , figure 2 As shown, a new type of shed cave that can resist landslides, including 4 face piles 1 arranged in rows and 4 back piles 2 arranged in rows, the cylindrical structure of the average radius of 1m of the face piles 1 and back piles 2, The distance between the adjacent face piles 1 and the adjacent back piles 2 is 6m to 8m, the back piles 2 are arranged on one side close to the mountain body, the face piles 1 are arranged on the other side, and the adjacent face piles 1 or the tops of adjacent back piles 2 are connected by top longitudinal beams 4, and the lower parts of adjacent surface piles 1 or adjacent back piles 2 are connected by bottom longitudinal beams 6, and the surface piles 1 and back piles 2 The tops of the tops are connected by top transverse beams 3, the bottom of the surface pile 1 and the back pile 2 are connected by a bottom beam 5, the bottom longitudinal beam 6 and the bottom beam 5 are arranged at the same height, and the...

Embodiment 2

[0044] Such as figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1, the face pile 1 is 0.5m to 1m higher than the back pile 2, the top of the top transverse tie beam 3 is flush with the top of the back pile 2, and is arranged on the face pile The support 7 on one side is 0.5m to 1m shorter than the support 7 on one side of the back pile 2 .

[0045] A construction method of a novel shed cave that can resist landslides as described in any one of embodiment 1 or embodiment 2, comprising the following steps:

[0046] 1) The surface pile 1 and the back pile 2 are respectively prepared by using the concrete pouring process: the back pile 2 and the surface pile 1 are inserted into the unstable soil body 10 in a row until the bottom is inserted into the embedded section stratum;

[0047] 2), using the concrete pouring process to prepare the top longitudinal beam 4 and the top transverse beam 3 respectively;

[0048] 3), when the top longitudinal beam 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com