Detachable deep submarine cable rolling winch

A detachable and winch technology, applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of submarine cable scrapping, achieve high reuse rate, reduce cable core damage, and reduce traction tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Each component in this embodiment is described one by one below:

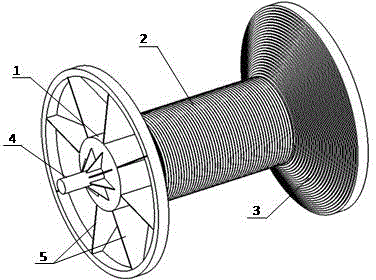

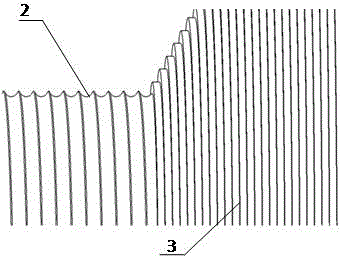

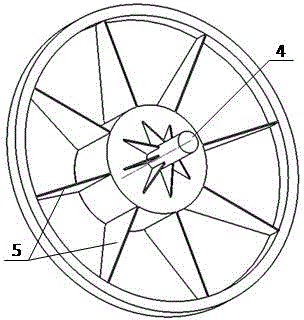

[0019] Such as Figure 1 to Figure 3 A detachable deep-sea cable winding winch is shown, including a winch body 1, the hub of the winch body 1 is covered with a detachable iron sheet 2 with grooves, and the tapered flange of the winch body 1 The inner side is covered with a detachable stepped iron plate 3, the tapered flange is a shell structure, and the tapered flange and the main shaft 4 are fixed by a trapezoidal spoke plate 5.

[0020] winch body such as figure 1 Shown, including smooth cylindrical flange, tapered flange. The flange is a thin-walled structure of the shell, which is funnel-shaped, supported by the trapezoidal web 5 and fixed with the central spindle. The number of 5 spokes at the flange on each side is not less than 8 spokes, which are symmetrically distributed and welded between the flange and the main shaft. The combination of the tapered flange and the web plate 5 can enhance t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com