Base plate material for rail fastener, preparation method and application of base plate material

A backing plate and fastener technology, which is applied in the direction of tracks, fixed rails, buildings, etc., can solve the problems of small-radius curved backing plate crushing failure, etc., and achieve the effect of increasing the ability to resist lateral deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1 The backing plate material for the rail fastener of the present invention

[0062] A backing plate material for rail fasteners, the backing plate material is made of A component and B component, wherein the A component is made from the raw materials of the following formula:

[0063]

[0064] B component is prepared by the reaction of 199g B-1PTMG2000 and 49.8g B-2 naphthalene diisocyanate (NDI), wherein the isocyanate content of B component is 5% (w / w);

[0065] The ratio of the amount of the isocyanate group in the B component to the amount of the hydroxyl group in the A component is 1.05;

[0066] The preparation method of the above-mentioned backing plate material comprises the following steps:

[0067] 1) 199g of PTMG2000 was heated to 130°C and dehydrated under vacuum for 2h;

[0068] 2) Keep the product obtained in step 1) at 130°C, and directly add the NDI of the formula amount. After the addition, the system will have a cooling phenomenon, and ...

Embodiment 2

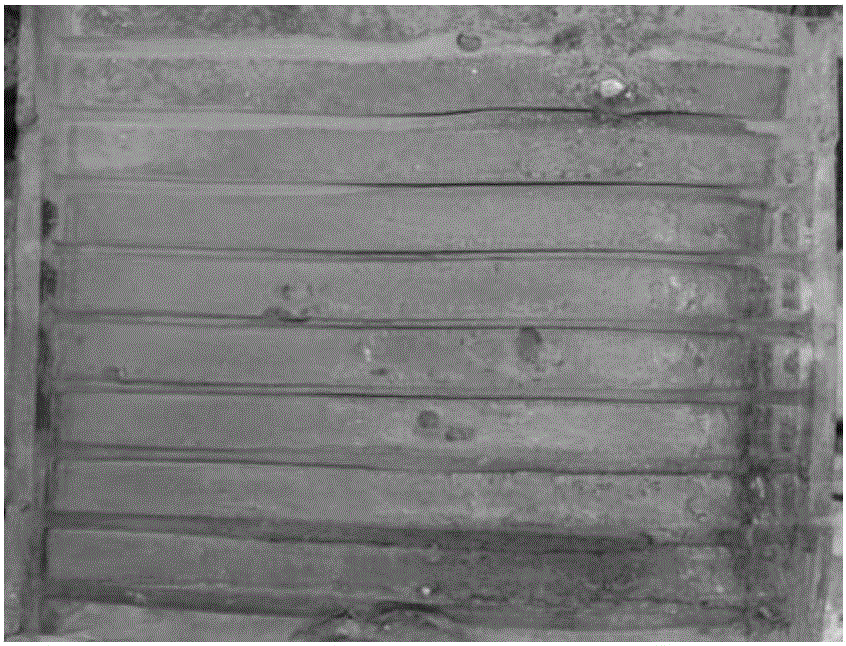

[0071] Example 2 Backing plate of the present invention

[0072] The backing material of Example 1 was used to prepare backing sheets of the present invention. The specific preparation method is as follows:

[0073] 1) 199g of PTMG2000 was heated to 130°C and dehydrated under vacuum for 2h;

[0074] 2) Keep the product obtained in step 1) at 130°C, and directly add the NDI of the formula amount. After the addition, the system will have a cooling phenomenon, and then the system will heat up due to the exothermic reaction, and the system temperature will reach 130°C for 30 minutes. ;

[0075] 3) After 30min, the system begins to cool down, and when it falls to 70°C, it is used as component B for standby;

[0076] 4) Fix the cloth between the upper and lower molds, with both ends longer than the size of the mold, and stretch both ends of the cloth to keep the cloth straight in the mold.

[0077] 5) Quickly mix the B component with a material temperature of 70 °C obtained in...

Embodiment 3

[0080] Example 3 Screening of Types of A-1 Chain Extenders

[0081] Using the raw materials of the formula shown in Table 1, the backing plate material for rail fasteners was prepared by the method shown in Example 1, and then the backing plate for rail fasteners was prepared by using this material and the method described in Example 2. When A-1 is 1,4-butanediol, ethylene glycol, 1,3-propanediol, 1,4-cyclohexanediol and diethylene glycol respectively, the pads are numbered 1#, 2 #, 3#, 4# and 5#. Then, the ratio of dynamic and static stiffness, compression set, Akron wear, rate of change of thickness after fatigue, rate of change of static stiffness after fatigue were measured respectively for the 5 groups of backing plates. Execution; Akron wear and compression set were performed in accordance with TB / T 2626-1995, and the results are shown in Table 1.

[0082] Table 1

[0083]

[0084]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com