Environment-friendly building energy-saving fireproof steel structure

A green building and steel structure technology, applied to building components, building structures, fire protection, etc., can solve problems such as corrosion, water waste, and reduced practicality of steel structure pillars, so as to avoid waste, reduce the probability of being corroded, and improve The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

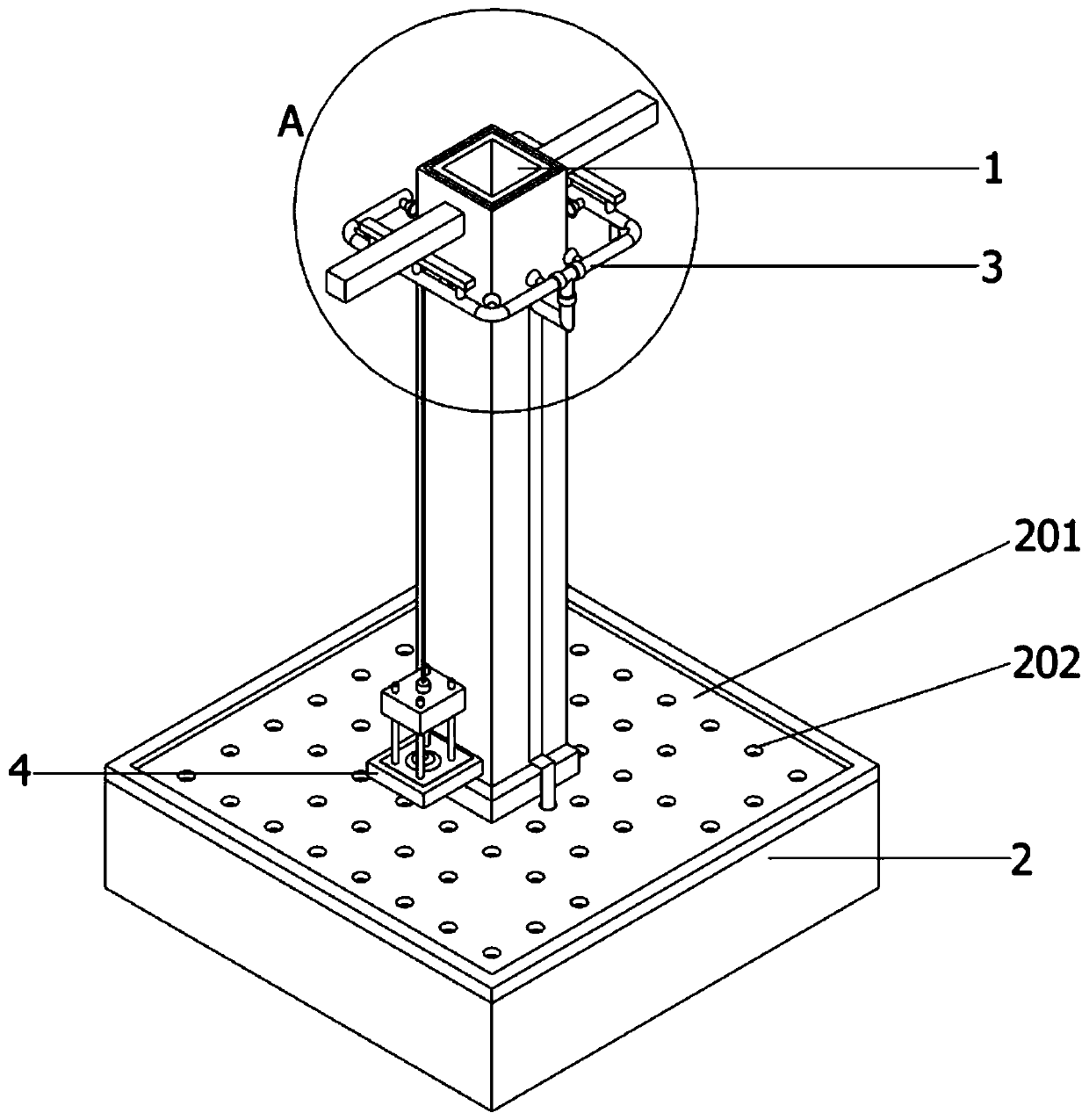

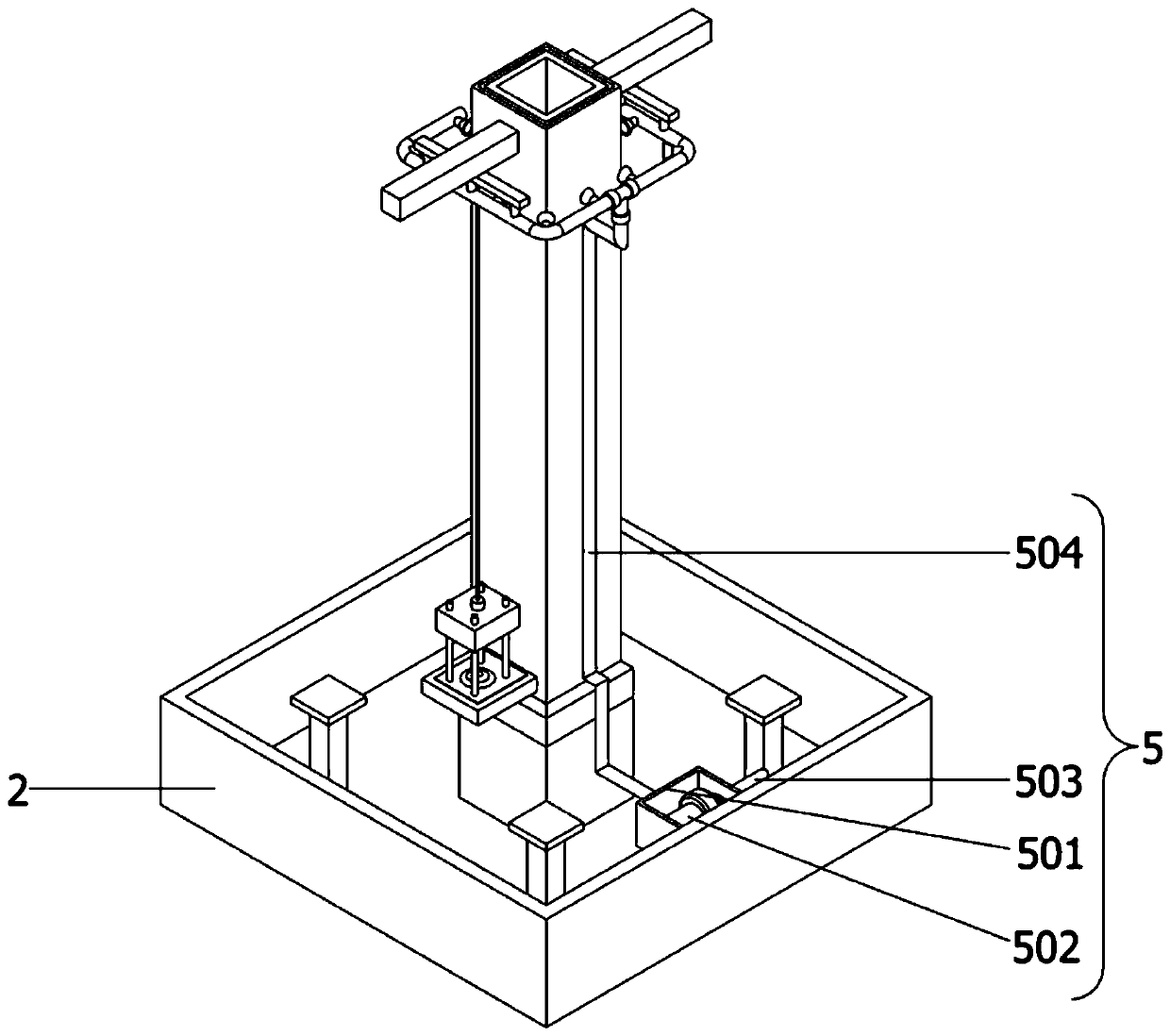

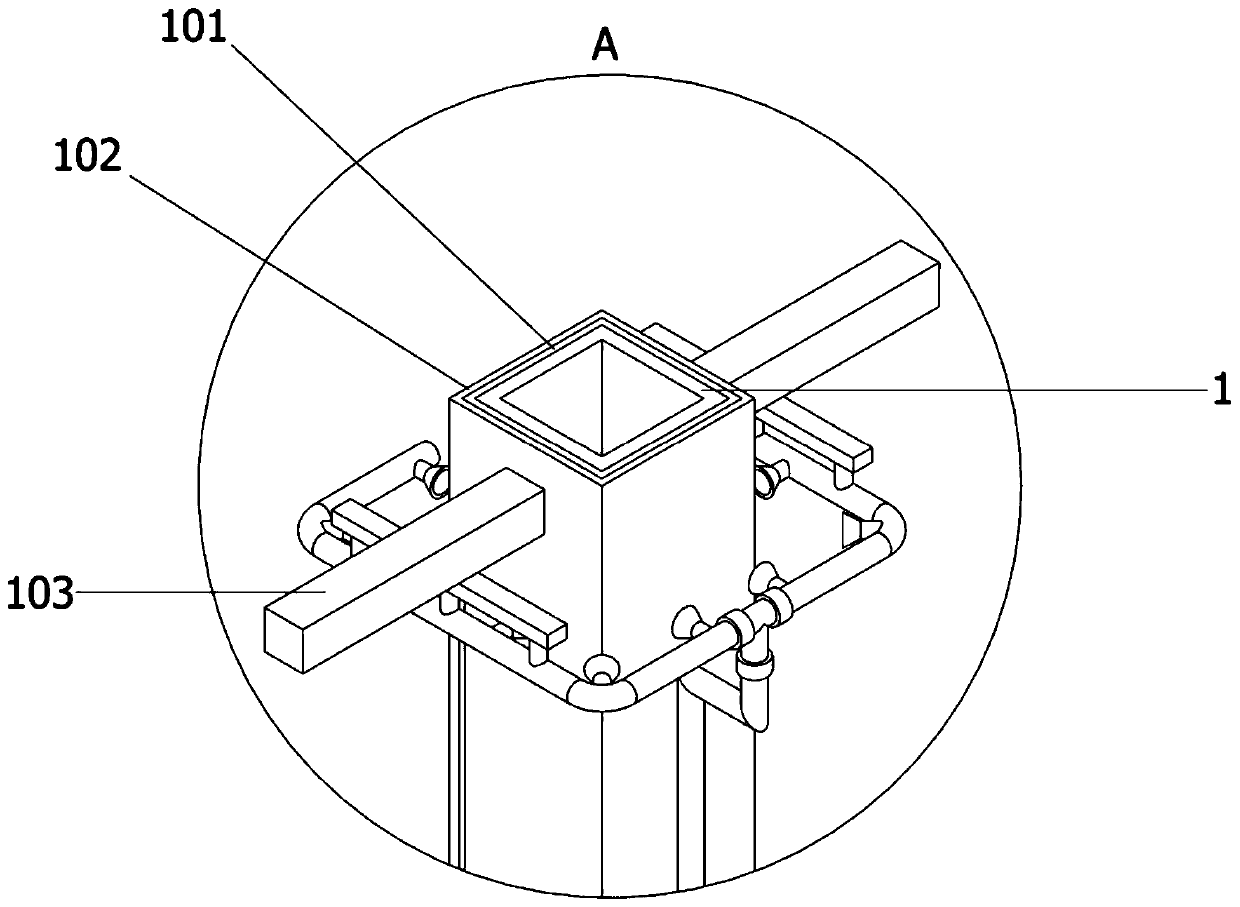

[0032] As attached figure 1 Attached Figure 8 Shown:

[0033] The present invention provides a green building energy-saving fireproof steel structure, which includes: a steel column 1, a water storage mechanism 2 is provided at the outer lower end of the steel column 1, and the water storage mechanism 2 further includes a cover 201, a water leakage hole 202, and a square column sleeve 203, The frame-shaped gasket 204 and the pillar 205 are equipped with a cover plate 201 on the top of the water storage mechanism 2 and a water leakage hole 202 is provided on the upper end of the cover plate 201. The sleeve 203 is sleeved on the outside of the fireproof layer 102 in the steel column 1, as attached figure 2 As shown, the upper end surface of the square column sleeve 203 is bonded with a frame-shaped gasket 204, the inner bottom end surface of the water storage mechanism 2 is provided with four pillars 205 in an annular array, and the top end surface of the pillar 205 is in contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com