A device and method for centering the power head of a vehicle-mounted drilling rig and a test bench

A drilling rig power head and centering device technology, which is applied to drilling equipment and methods, rotary drilling rigs, directional drilling, etc., can solve the problems such as the difficulty of centering the power head and the axis of the test bench, so as to avoid the failure or even damage of the test bench , to ensure the effect of smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

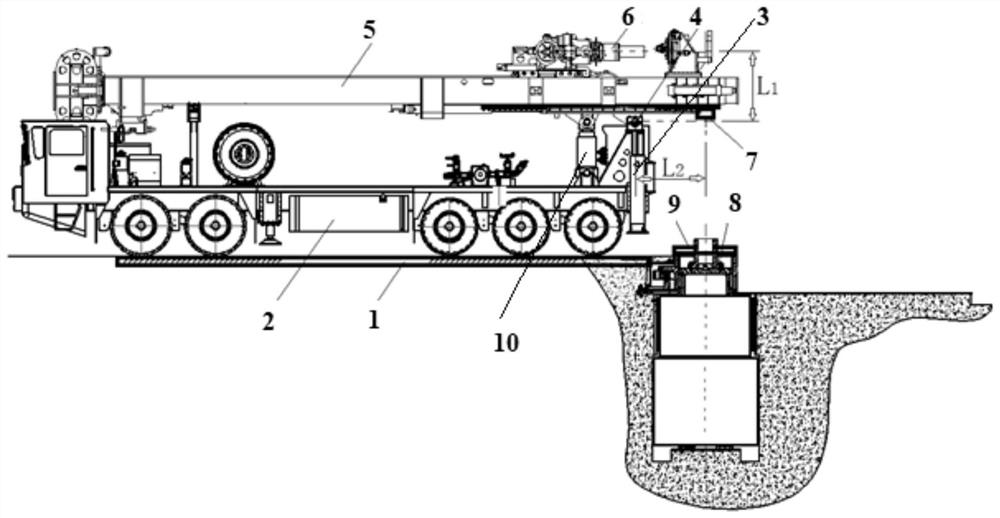

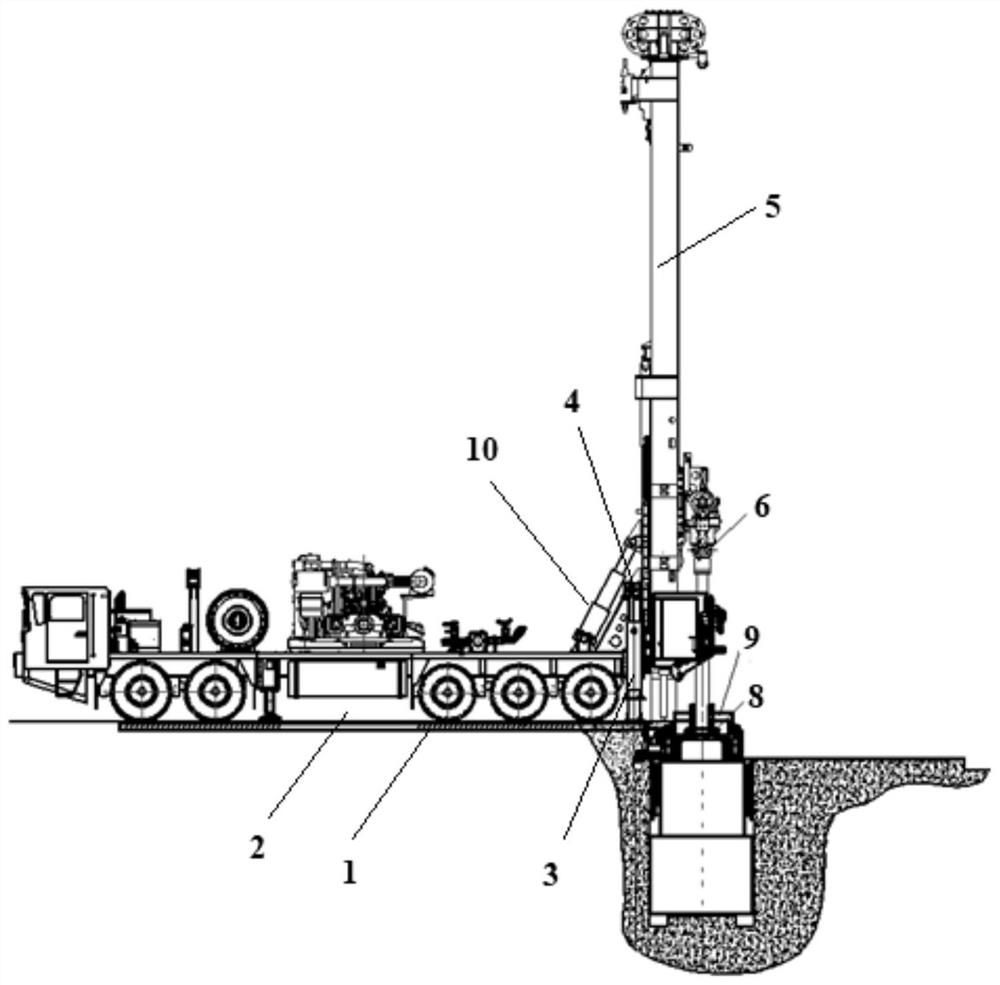

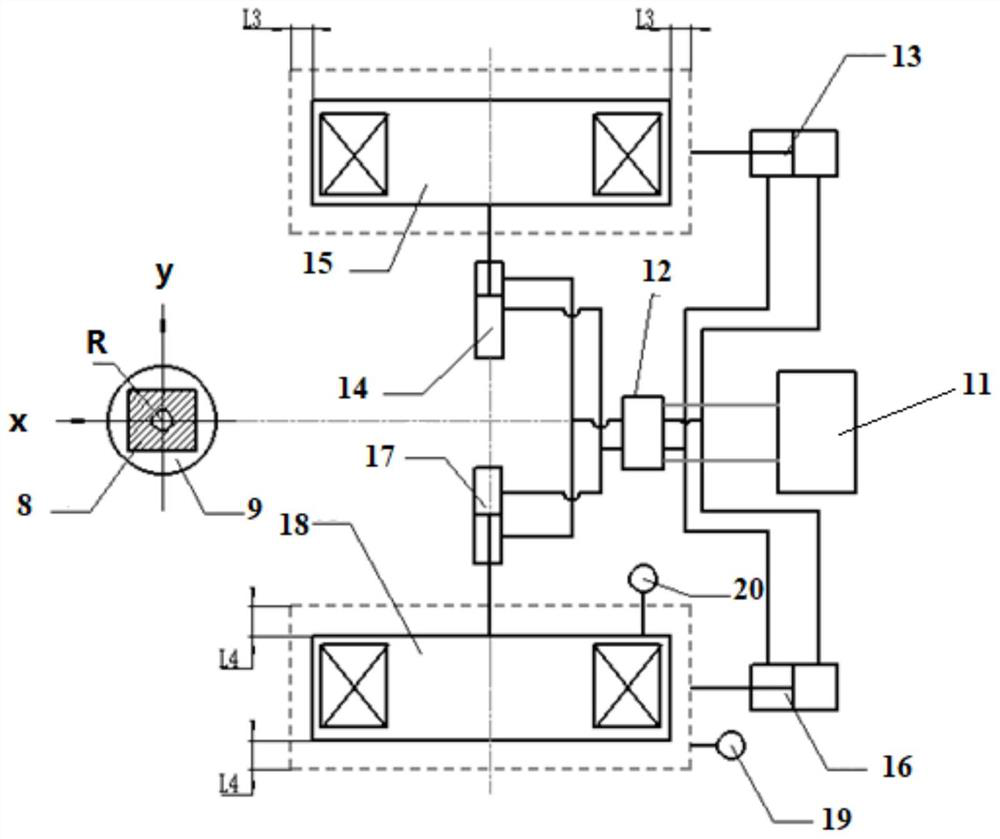

[0038] Such as Figure 1 to Figure 4 As shown, the present embodiment provides a vehicle-mounted drilling rig power head and a test bench centering device, including a translation system 1, a drilling rig vehicle 2 arranged on the translation system 1, a vertical rear support 3 arranged at the rear end of the drilling rig vehicle 2, The feeding frame 5 that is positioned above the drilling machine 2 and the rear frame 3 and is hinged to the upper end of the rear frame 3 through the hinge shaft 4, the power head 6 that is arranged on the feed frame 5 and is parallel to the feed frame 5, is located on the The laser signal emitter 7 at the lower end of the rear part of the feed fuselage 5 and the laser emission direction is perpendicular to the feed fuselage 5, the drilling rig performance test bench 8 located below the laser signal emitter 7, and the horizontal level on the drill rig performance test bench 8. The laser signal receiving dish 9 of layout; The central axis of power...

Embodiment 2

[0045] This embodiment also provides a method for centering the power head of the vehicle-mounted drilling rig and the test bench, which is realized by using the centering device for the power head of the vehicle-mounted drilling rig and the test bench in Embodiment 1;

[0046] Specifically include the following steps:

[0047] In the first step, the driver drives the drilling rig to the designated position, so that the outriggers of the drilling rig are within the range of the left mobile platform and the right mobile platform, and the laser signal transmitter can be projected onto the laser signal receiving plate to complete the performance test of the power head and the drilling rig rough centering;

[0048] In the second step, according to the projection position of the laser signal transmitter received by the laser signal receiving disc, the left mobile platform and the right mobile platform move synchronously, and the right X-direction worktable and the right Y-direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com