Hydrogen circulating pump oil leakage prevention device and method thereof

A technology for preventing oil leakage and circulating pumps, applied in the sealing device of piston pumps, parts of pumping devices for elastic fluids, pump components, etc., to achieve protection from damage, control manufacturing costs, and simple and easy structural improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

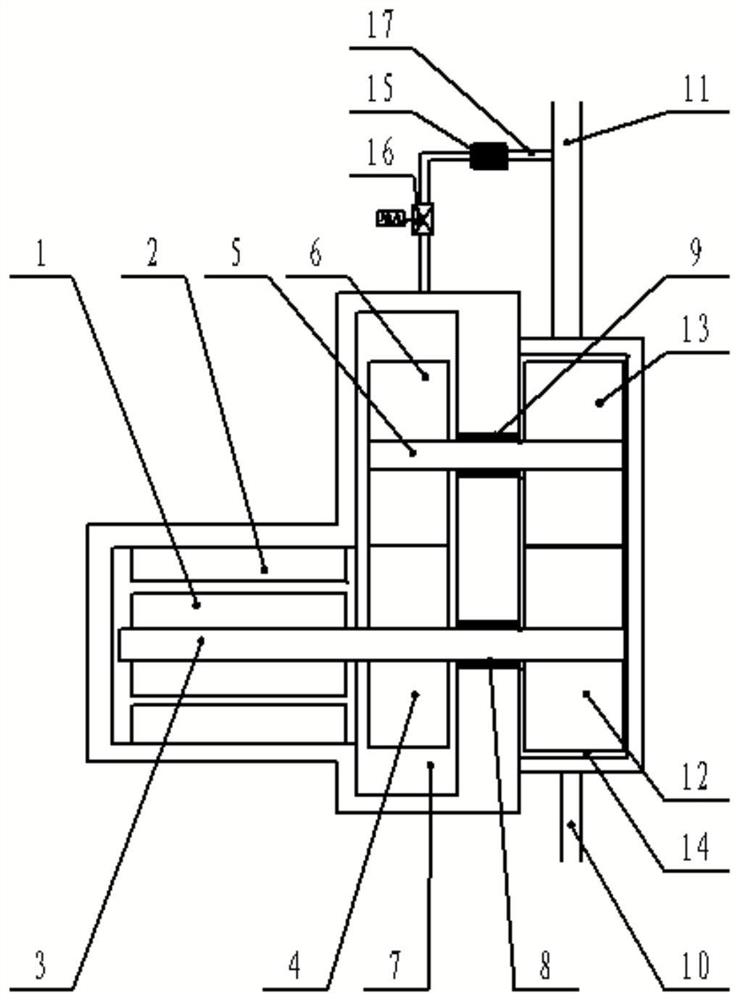

[0027] Example 1, such as figure 1 As shown, the application of the hydrogen circulation pump of the oil leakage prevention device described in the present application, the driving gear 4 and the driving rotor 12 are installed on the driving shaft 3, and the driven gear 6 and the driven rotor 13 are installed on the driven shaft 5;

[0028] The driving gear 4 and the driven gear 6 are located in the gear chamber 7, and there is lubricating oil in the gear chamber 7;

[0029] The driving rotor 12 and the driven rotor 13 are located in the compression chamber 14;

[0030] Hydrogen enters the compression chamber 14 from the intake pipeline 11, and is discharged from the exhaust pipe 10 after the driving rotor 12 and the driven rotor 13 rotate together, engage and compress;

[0031] Between the gear chamber 7 and the compression chamber 14, the driving shaft 3 is provided with a first seal 8, and the driven shaft 5 is provided with a second seal 9;

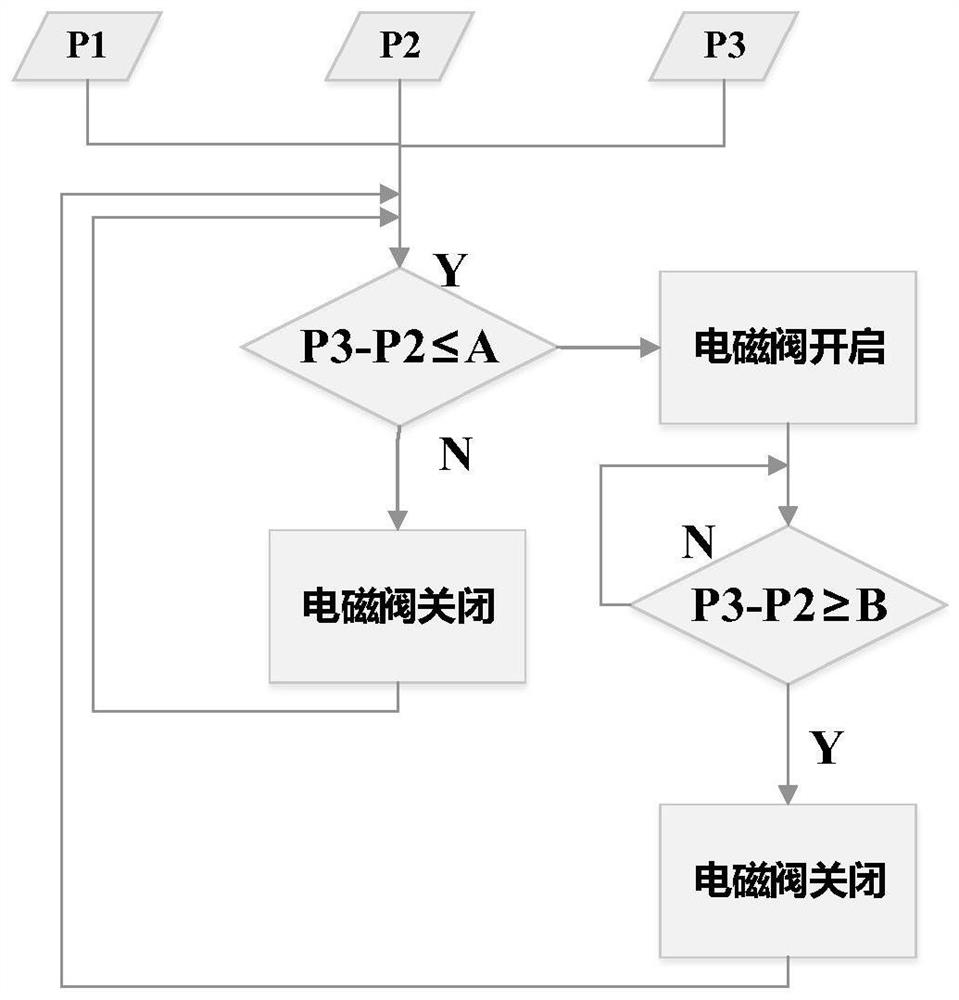

[0032] There is a pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com