Real-time three-dimensional measurement method based on primary projection structured light parallel stripe pattern

A fringe pattern and structured light technology, applied in the field of optical three-dimensional sensing, can solve the problems of low measurement accuracy and poor ability to resist external light interference, and solve the problems of low accuracy, inability to measure moving or deformed objects, and obvious contrast Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below according to the accompanying drawings and working principle.

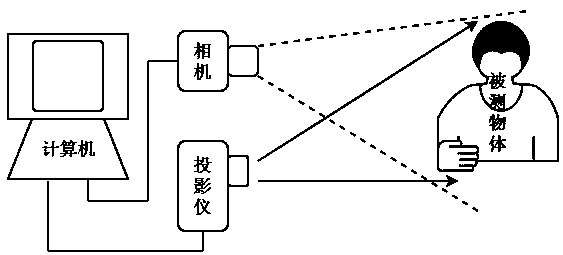

[0012] attached figure 1 It is a system structure diagram of the present invention. Including an industrial camera, an industrial projector and a high-performance computer. In order to ensure the resolution of the 3D reconstruction results, the resolutions of the industrial camera and the industrial projector are respectively selected as 1280×1024 and 1920×1080 or higher. The image capture frame rate of the camera and the projection frame rate of the projector are both greater than 10 frames per second. Because fringe pattern generation, image capture, image processing and 3D reconstruction are all done by computer, in order to meet real-time requirements, the computer is selected as i7-6700 CPU@ 3.4GHz 16G ram or higher performance configuration.

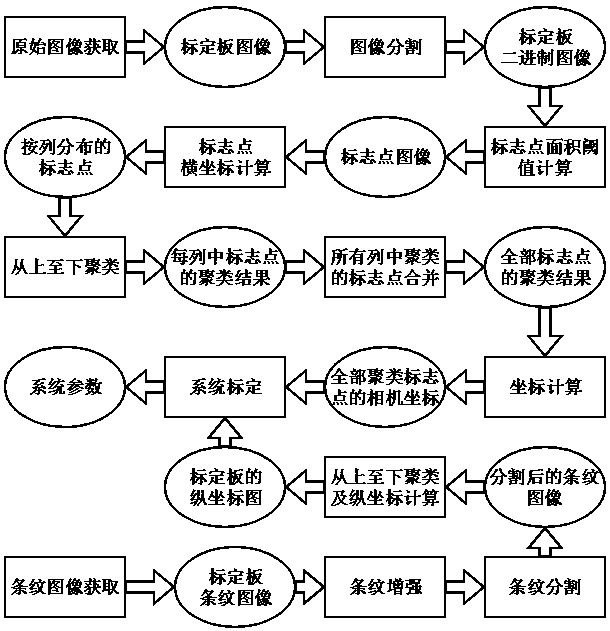

[0013] attached figure 2 It is the system calibration flowchart of the present invention. It mainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com