SFP28 SR optical module structure of COB process

A technology of optical modules and processes, applied in the direction of light guides, optics, optical components, etc., can solve the problems not involved in the connection method of COB micro-optical components, achieve the effects of stable performance, reduce high-frequency signal leakage, and avoid interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

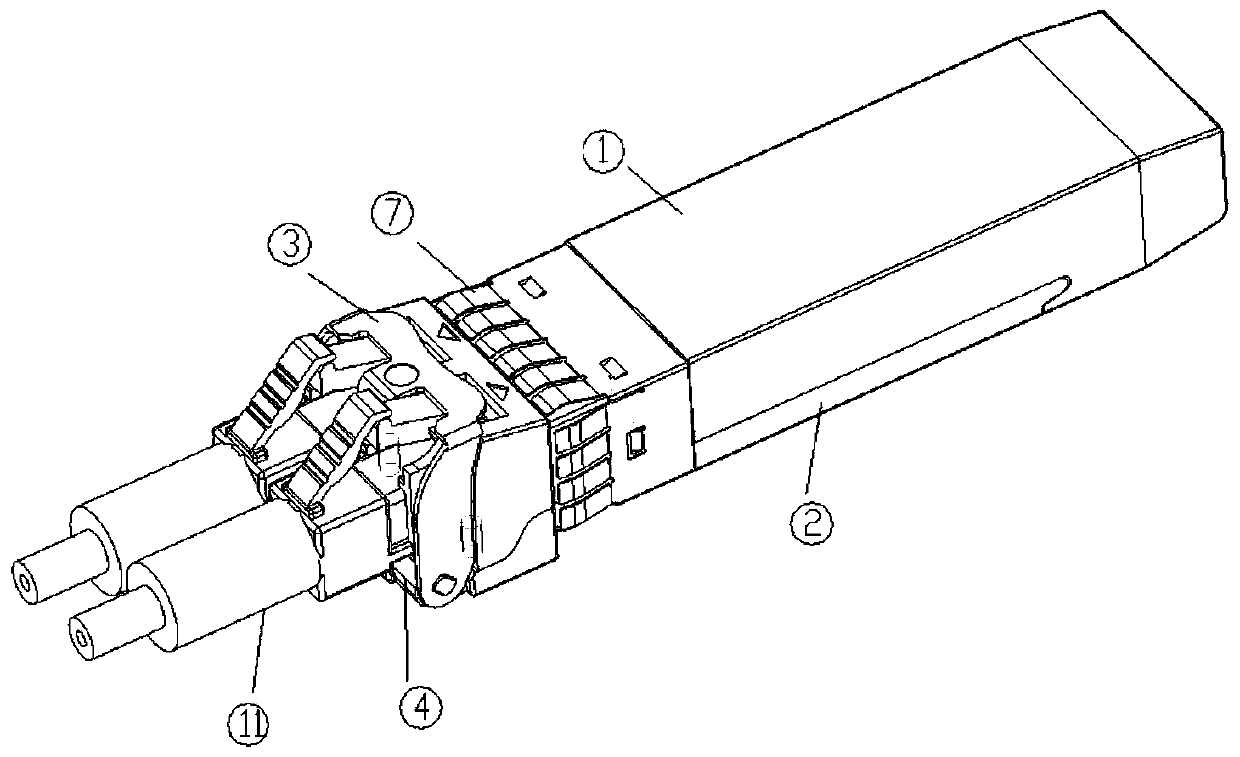

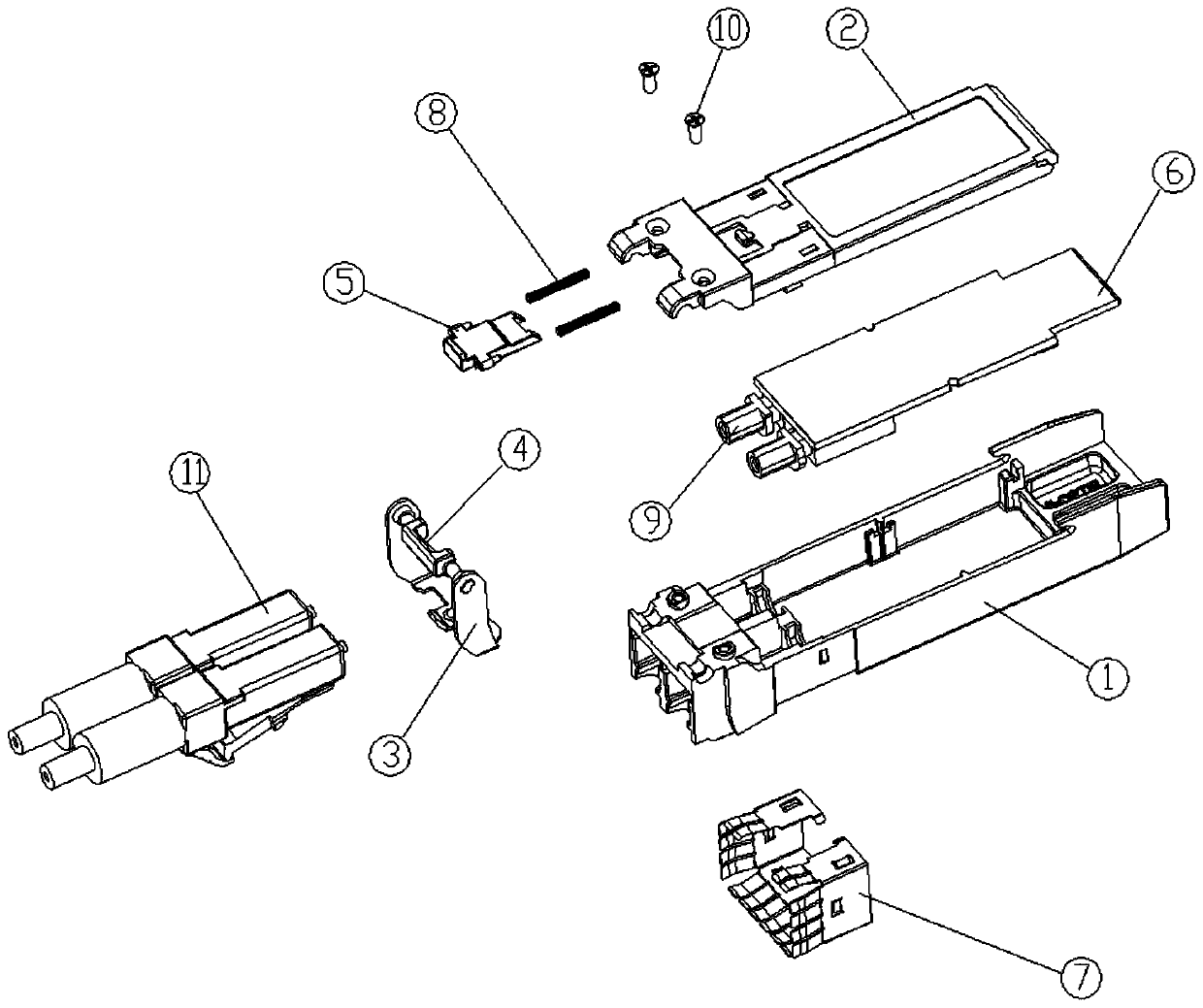

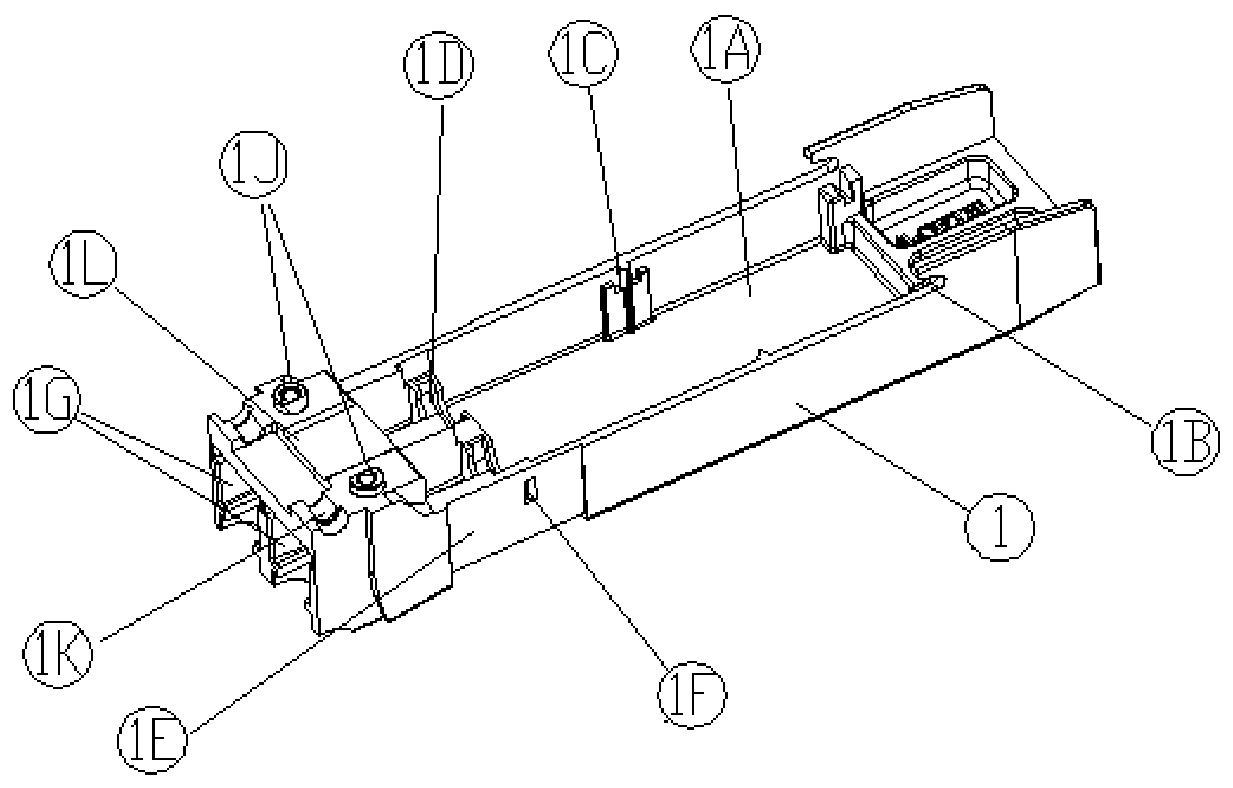

[0035] Such as figure 1 and figure 2 As shown, the present invention mainly includes the following components: base 1, upper cover 2, pull ring 3, unlocking cam 4, slider 5, circuit board 6, EMI shielding shrapnel 7, spring 8, micro-optical assembly 9, screw 10, LC jumper 11, wherein the base 1 and the upper cover 2 form a housing, and the unlocking mechanism of the module is composed of the pull ring 3, the unlocking cam 4, the slider 5 and the spring 8 in cooperation with the structure of the base 1 and the upper cover 2. The optical component 9 is arranged at one end of the circuit board 6 and plugged into the LC jumper 11 through the LC optical interface. The housing of this example is a cavity with an open tail end, a partition wall is provided at the front end of the middle part of the housing, and an assembly hole matching the cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com