High specific capacity lithium ion battery material, preparation method and lithium ion battery

A lithium-ion battery, high specific capacity technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor rate performance, unsatisfactory cycle performance, and limit the application of lithium-ion batteries, and achieve increased structural stability. The effect of buffering the volume expansion stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

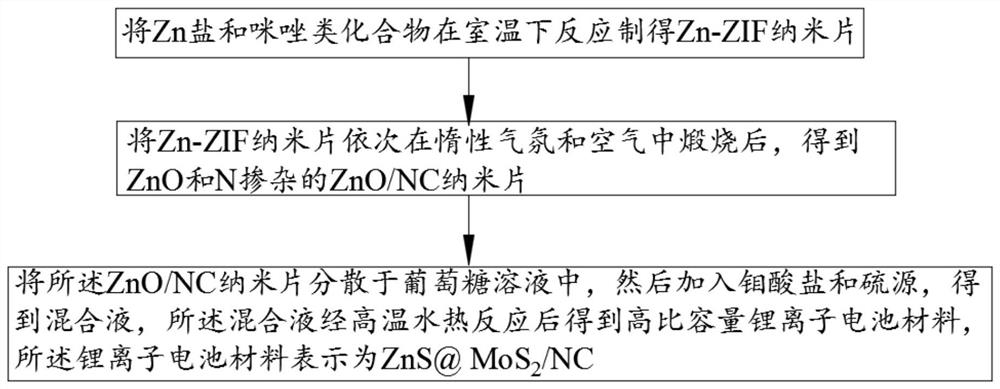

[0036] A preparation method of a high specific capacity lithium ion battery material provided by an embodiment of the present invention comprises the following steps:

[0037] S1, Zn salt and imidazole compounds are reacted at room temperature to prepare Zn-ZIF nanosheets;

[0038] S2, after sequentially calcining the Zn-ZIF nanosheets in an inert atmosphere and an air atmosphere, to obtain ZnO / NC nanosheets;

[0039] S3, dispersing the ZnO / NC nanosheets in the glucose solution, and then adding molybdate and sulfur source to obtain a mixed solution, the mixed solution is subjected to a high-temperature hydrothermal reaction to obtain a high specific capacity lithium-ion battery material, the The lithium-ion battery material is expressed as ZnS@MoS 2 / NC.

[0040] Further, in step S1, the Zn salt is selected from one or more of zinc nitrate hexahydrate, zinc sulfate heptahydrate and zinc chloride. The imidazole compound is selected from one or more of 2-methylimidazole, 4-ni...

Embodiment 1

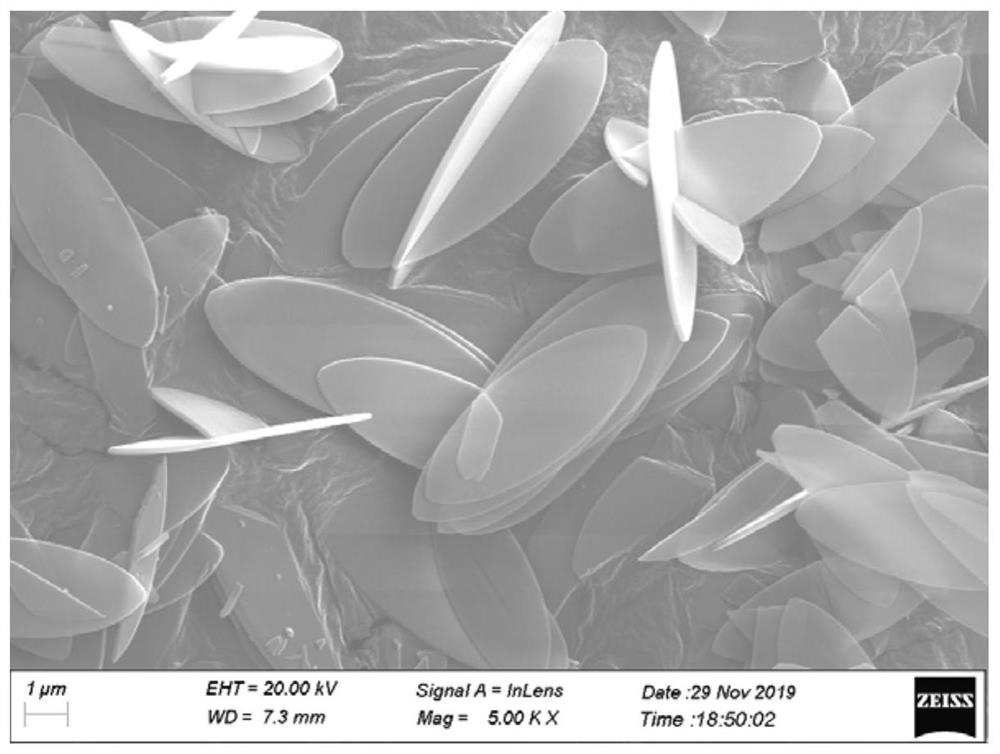

[0054] A high specific capacity lithium-ion battery material (ZnS@MoS) provided in this embodiment 2 / NC), which were prepared according to the following steps:

[0055] (1) Preparation of Zn-ZIF nanosheets: take Zn(NO 3 ) 2 6H 2 O and 2-methylimidazole were dissolved in methanol to prepare 2mmol / L cobalt nitrate hexahydrate solution and 12mmol / L 2-methylimidazole solution. Pour the cobalt nitrate hexahydrate solution into the 2-methylimidazole solution at a constant speed according to the volume ratio of 1:1 at room temperature, and stir while adding. After the addition, the mixture was magnetically stirred at room temperature for 4 hours, and a white precipitate was obtained after repeated centrifugation and deionized water washing operations. The precipitate was vacuum-dried at 60° C. to obtain white powdery Zn-ZIF nanosheets.

[0056] (2) Preparation of ZnO / NC nanosheets: in N 2 In the atmosphere, the Zn-ZIF nanosheets were heated to 650 °C at a heating rate of 1 °C / ...

Embodiment 2

[0060] A high specific capacity lithium-ion battery material (ZnS@MoS) provided in this embodiment 2 / NC), which were prepared according to the following steps:

[0061] (1) Preparation of Zn-ZIF nanosheets: prepared according to the method provided in Example 1.

[0062] (2) Preparation of ZnO / NC nanosheets: prepared according to the method provided in Example 1.

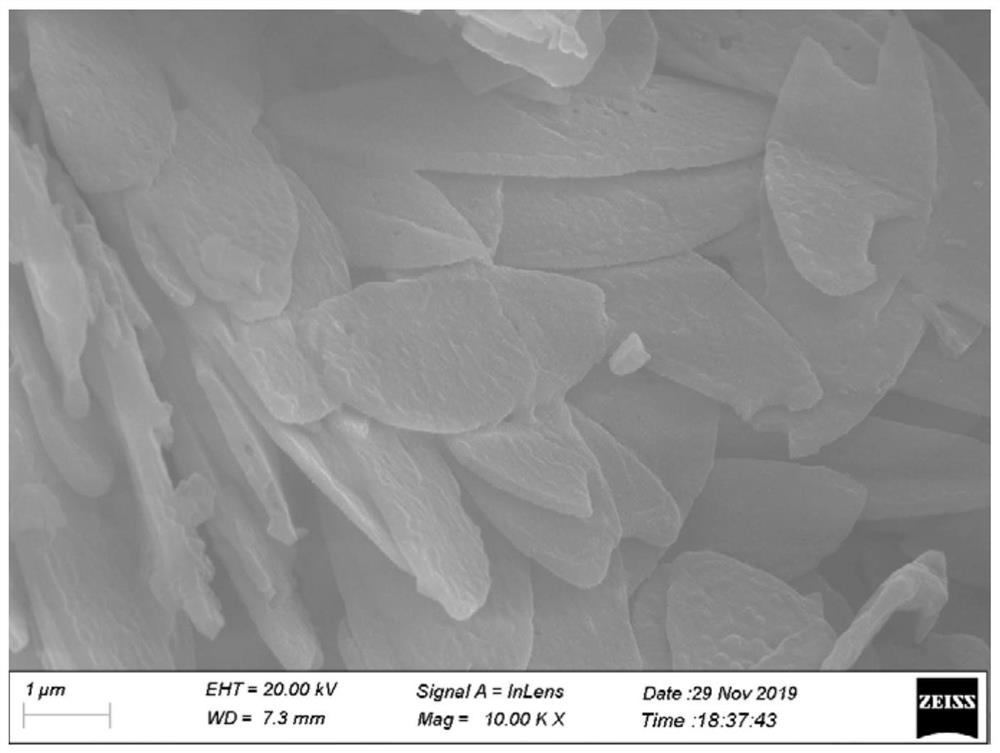

[0063] (3) Preparation of ZnS@MoS 2 / NC nanosheets: Disperse 0.05 g of ZnO / NC nanosheets in 30 ml of glucose solution with a concentration of 0.1mol / L and stir evenly, then add 0.3 g of ammonium molybdate ((NH 4 ) 2 MoO 4 ) and 0.6 g of thioacetamide were mixed uniformly to obtain a mixed solution. The mixture was transferred to a stainless steel autoclave, heated to 180 °C and kept for 24 h, then naturally cooled to room temperature. The reactants were collected by centrifugation and washed with water, and dried in a vacuum oven at 60°C for 12 hours to obtain ZnS@MoS 2 / NC nanosheets.

[0064] at 500 mA g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com