Motor, compressor and refrigeration equipment

A compressor and rotor technology, applied in the field of refrigeration equipment, can solve the problems of affecting the sense of hearing, large vibration and noise, etc., and achieve the effects of stable electromagnetic wave waveform, low vibration and noise, and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

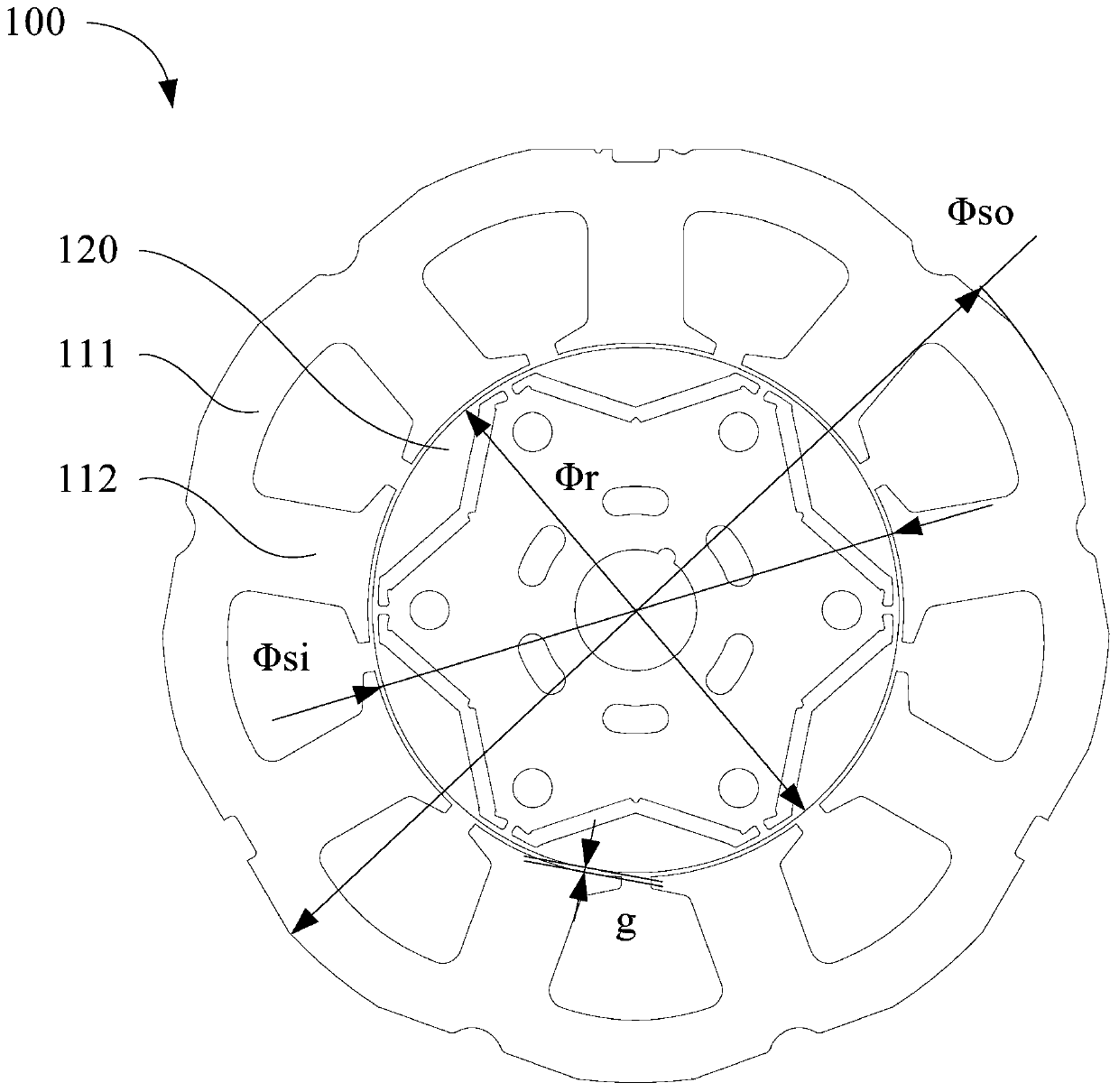

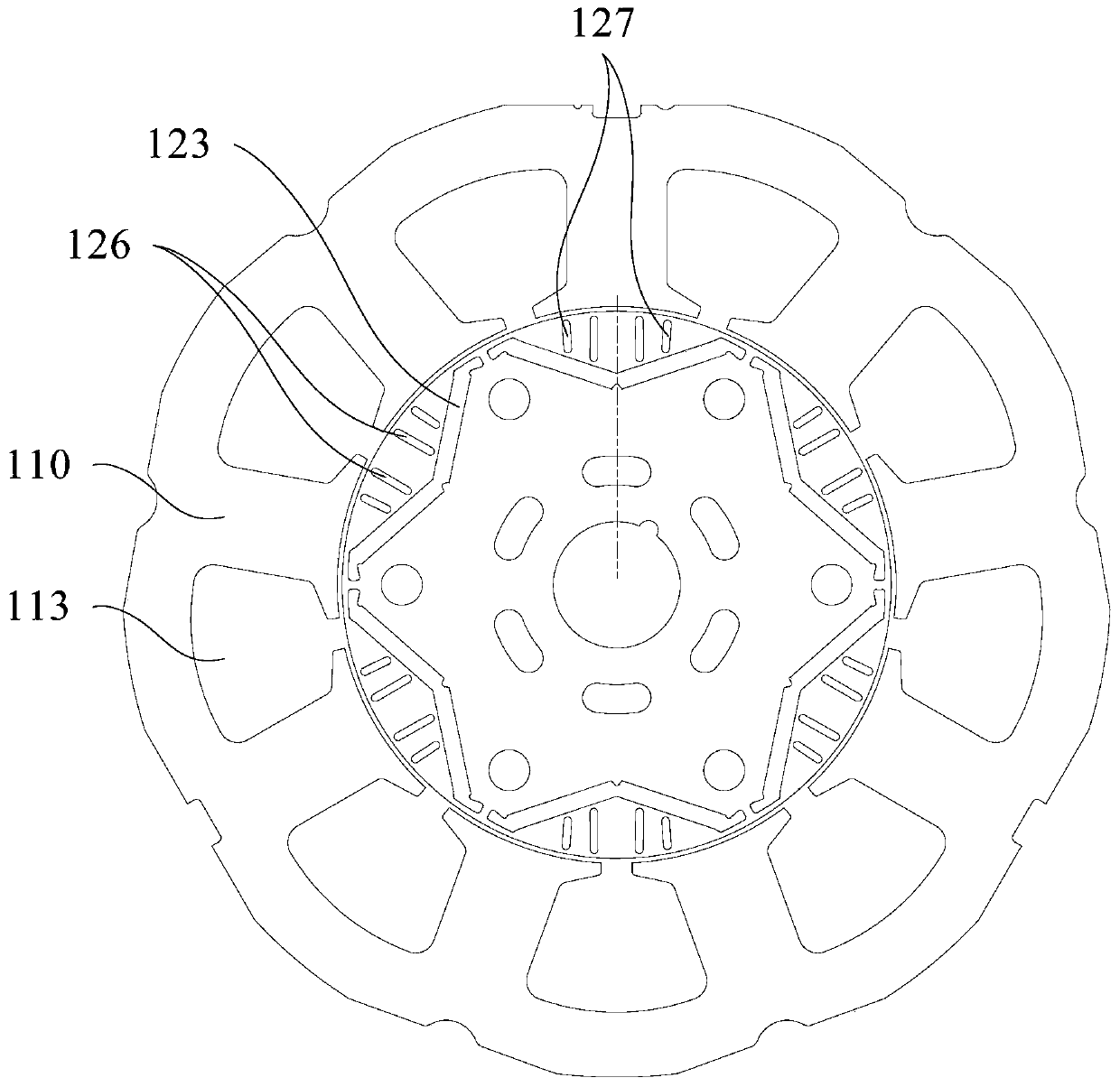

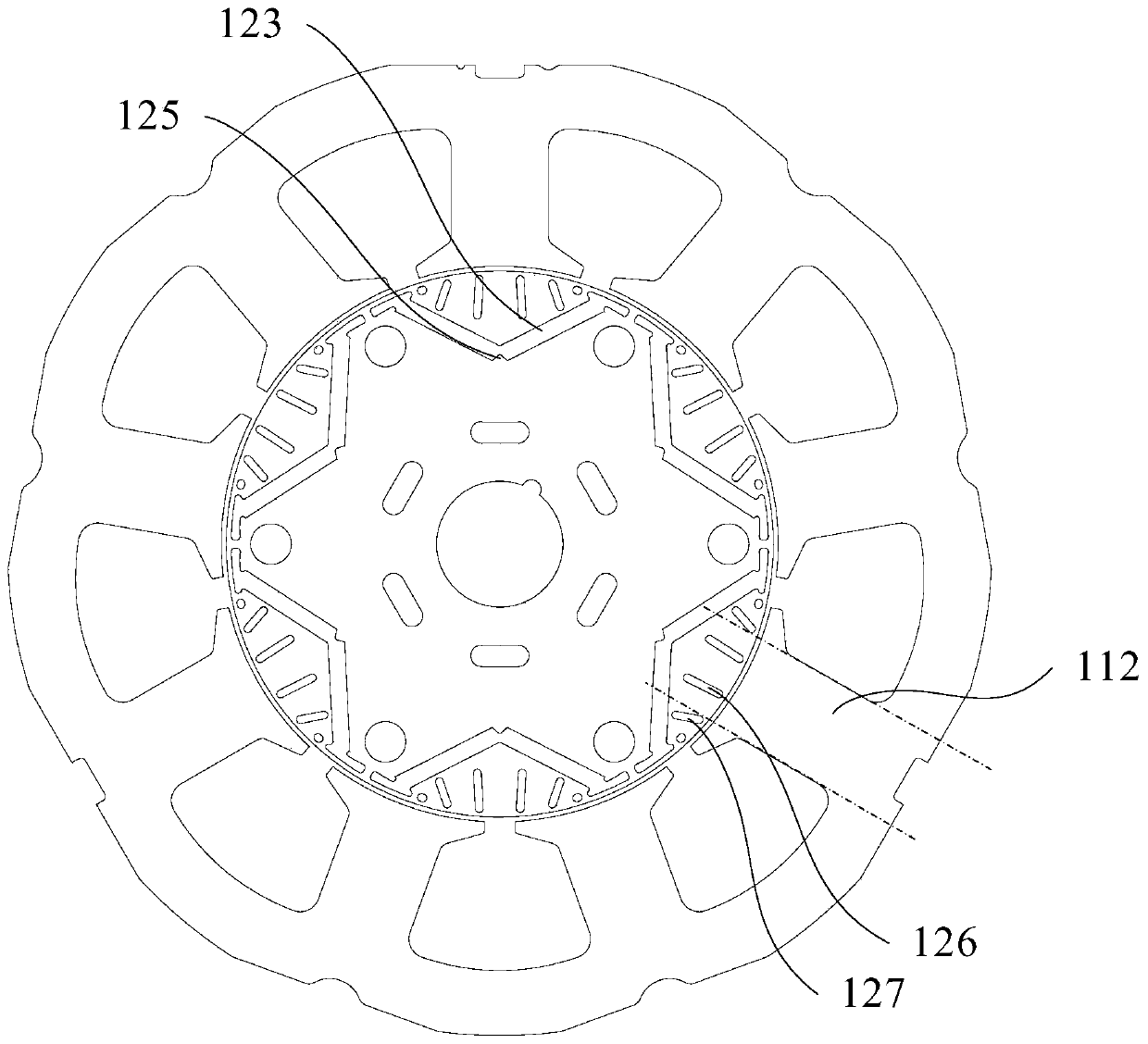

[0105] Such as Figure 1 to Figure 3 As shown, a motor 100 includes a stator 110 and a rotor 120 , and the stator 110 surrounds the outer periphery of the rotor 120 . The stator 110 includes a stator core 111, the stator iron core 111 includes a plurality of stator teeth 112, the plurality of stator teeth 112 are distributed around the rotor 120 in the circumferential direction, a stator slot 113 is formed between two adjacent stator teeth 112, and a plurality of coils pass through The stator slots 113 are wound around the plurality of stator teeth 112 . The rotor 120 includes a rotor core 121 and a plurality of permanent magnets 122. The rotor core 121 is provided with a plurality of slots 123, and the plurality of slots 123 are circumferentially distributed around the center line of rotation of the rotor core 121. The plurality of permanent magnets 122 disposed in a plurality of slots 123 .

[0106] Further, the rotor core 121 is formed by stamping a plurality of rotors 12...

Embodiment 2

[0113] On the basis of the first embodiment above, as figure 1 As shown, the gap g between the stator 110 and the rotor 120 and the outer diameter Φr of the rotor 120 are further defined, satisfying 180≤Φr / g 2 ≤240.

[0114]In this embodiment, by setting the ratio of the outer diameter Φr of the rotor 120 to the square of the gap g between the stator 110 and the rotor 120 between 180 and 240, it is possible to ensure that the outer diameter Φr of the rotor 120 is larger. At the same time, ensure that there is a sufficient gap g between the stator 110 and the rotor 120. On the one hand, it is beneficial to increase the mass of the rotor 120, change the natural frequency of the rotor 120, and avoid the vibration noise of the shaft system caused by the relatively light weight of the rotor 120 in the related art. Larger problems are beneficial to reduce the operating noise of the motor 100 and the compressor 200, improve user experience, and significantly improve the hearing of a...

Embodiment 3

[0126] On the basis of any of the above embodiments, the gap g between the stator 110 and the rotor 120 is further defined to satisfy 0.5mm≤g≤0.55mm. On the one hand, it is beneficial for the rotor 120 to rotate smoothly in the stator 110 without bumping; To solve the problem of high vibration and noise, reduce the running noise of the motor 100 and the compressor 200 . Moreover, when the inner diameter Φsi of the stator 110 and the outer diameter Φso of the stator 110 satisfy 0.558≤Φsi / Φso≤0.576, and / or the gap g between the stator 110 and the rotor 120 and the outer diameter Φr of the rotor 120 satisfy 180≤Φr In the case of / g2≤240, and / or the moment of inertia J of the rotor 120, the gap g between the stator 110 and the rotor 120, the mass m of the rotor 120, and the outer diameter Φr of the rotor 120, satisfy 230≤J / g 2 ≤340, J=0.5m×Φr 2 In the case of , the weight of the rotor 120 can be better increased while ensuring the performance of the motor 100 , thereby reducing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com