Motor, compressor and air conditioner

A compressor and permanent magnet motor technology, applied in the field of compression equipment, can solve the problems that the motor parameters have a great influence on the performance of the whole machine, the compressor cannot achieve high-speed operation, the back EMF, and the inductance parameter are large, so as to improve the operation stability performance, reduce inductance, and increase the effect of operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

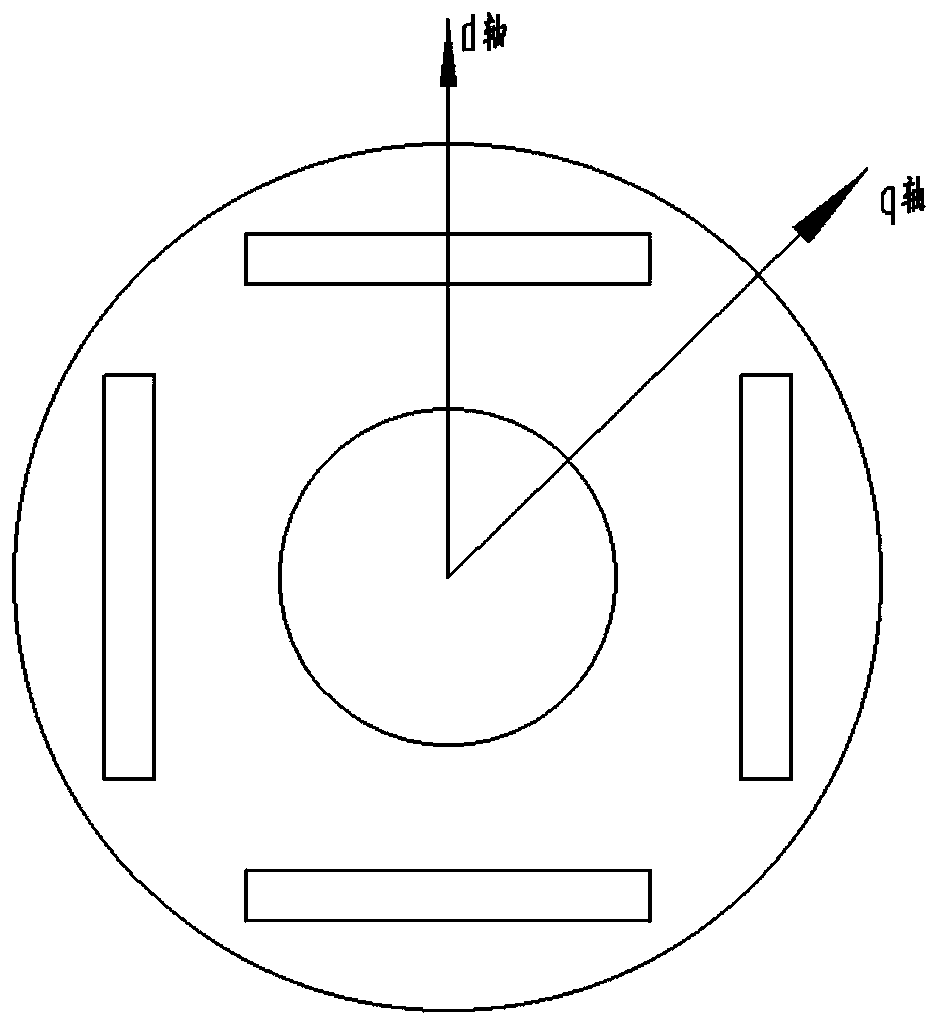

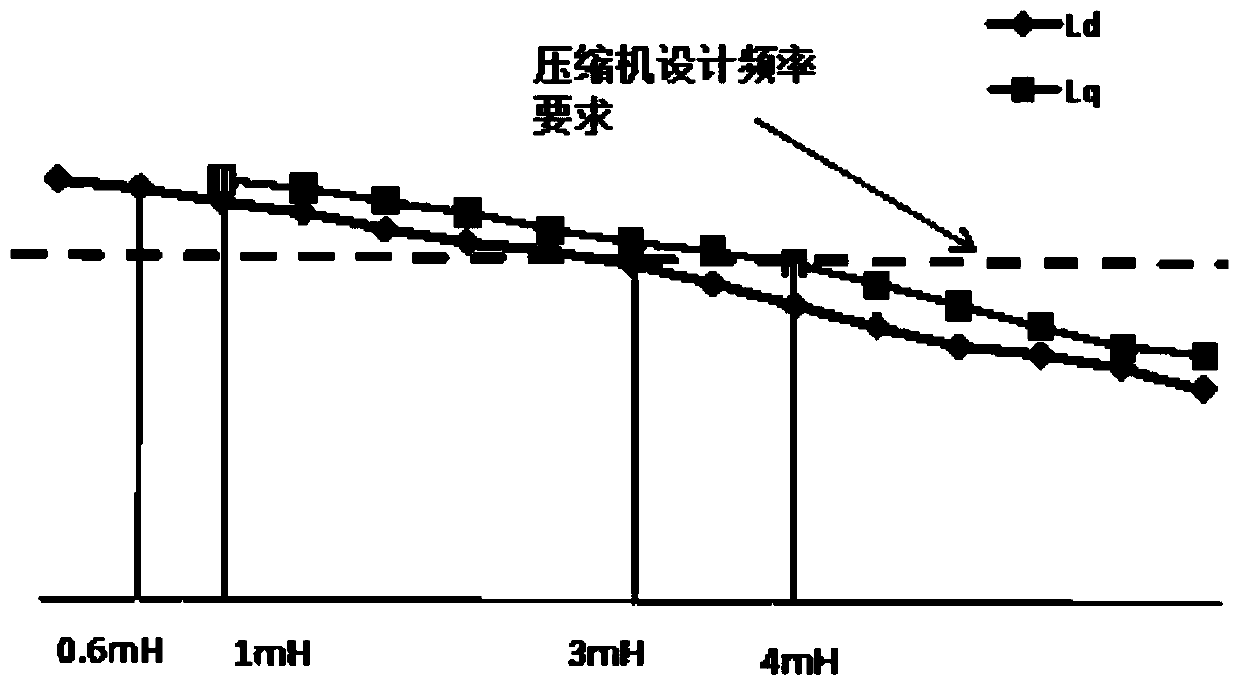

[0018] see in conjunction Figure 1 to Figure 2 As shown, according to the embodiment of the present application, a motor is provided, and the operating parameters of the motor satisfy: 0.6mH≤Ld≤3mH, 1mH≤Lq≤4mH; -0.4mH≤Lq-Ld≤2mH; wherein, Ld is the d-axis inductance, Lq is the q-axis inductance of the motor.

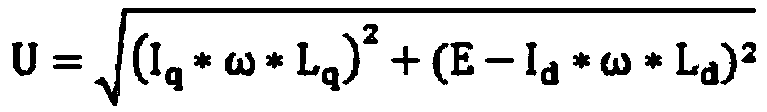

[0019] During the design process of the motor of the rotor compressor, it operates at different frequencies, and its motor terminal voltage conforms to the following voltage formula;

[0020]

[0021] Among them, under the special controller, if the motor is to run at the required speed, it needs to meet U≤U0 at the speed, U is the effective value of the motor running terminal voltage; E is the motor induction potential corresponding to different ω speeds; Lq , Ld are the q-axis and d-axis inductance of the motor respectively; Iq and Id are the q-axis and d-axis current components of the compressor running under a certain working condition; U0 is the effective value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com