Baking tray structure and oven equipment

A baking pan and air guide structure technology, which is applied in the direction of roasters/barbecue grids, kitchen utensils, home utensils, etc. It can solve the problems of inconvenient indoor use, inability to achieve rich aroma of charcoal roasting, and inability to meet the needs of consumers for gourmet food. , to achieve the effect of small occupied space, rich taste and easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

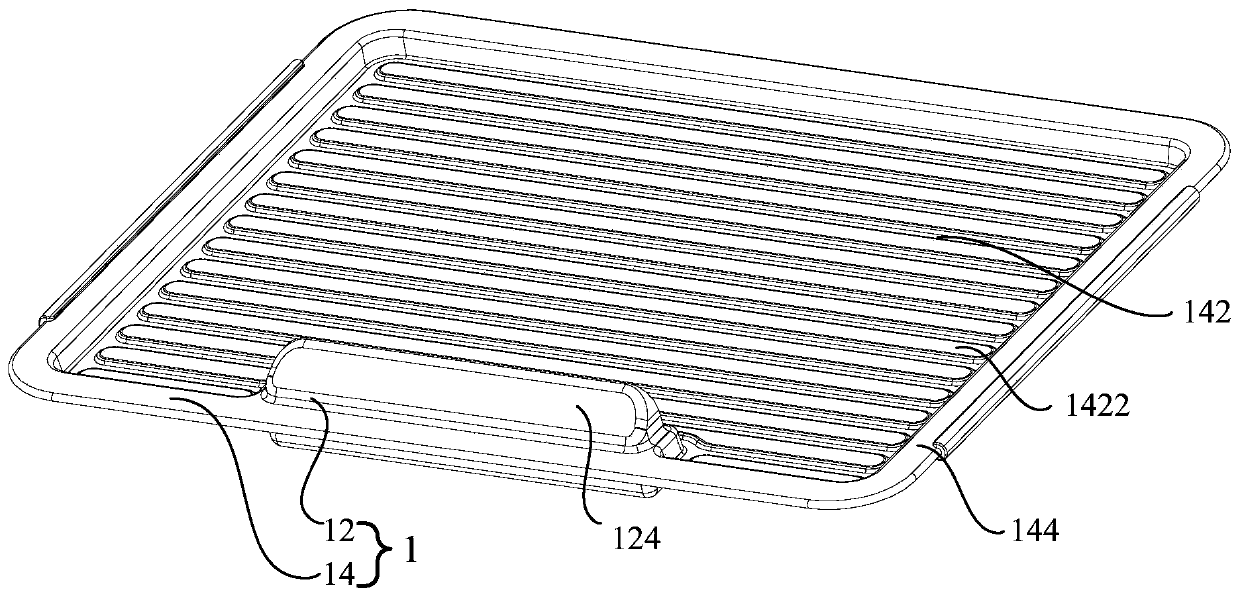

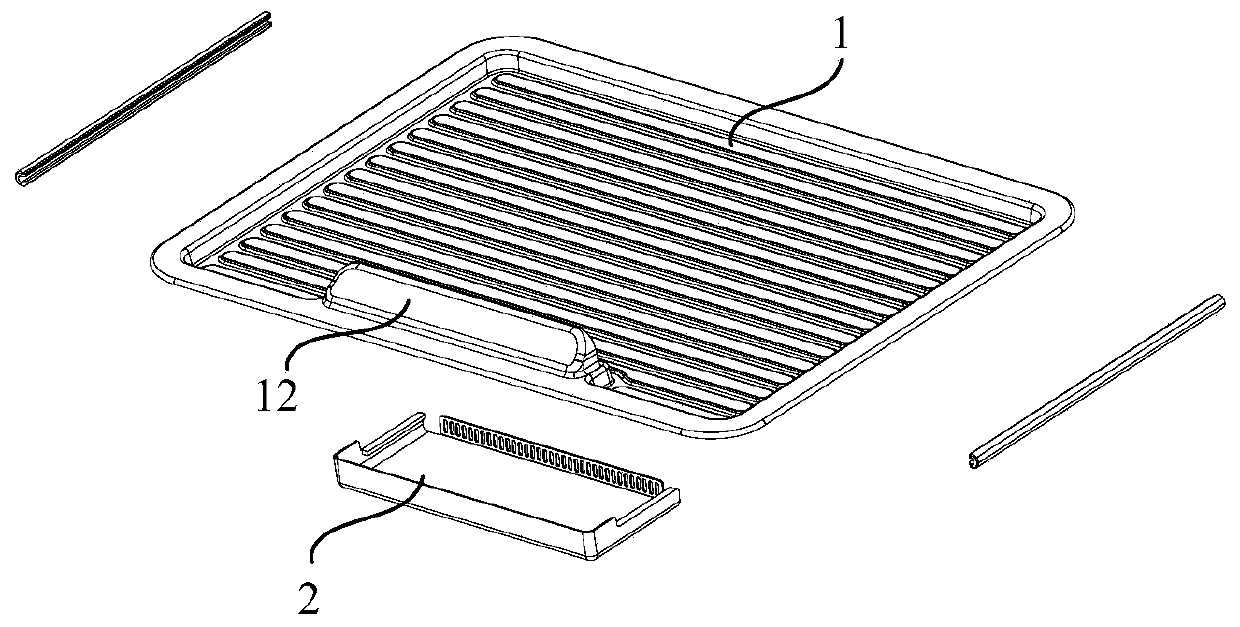

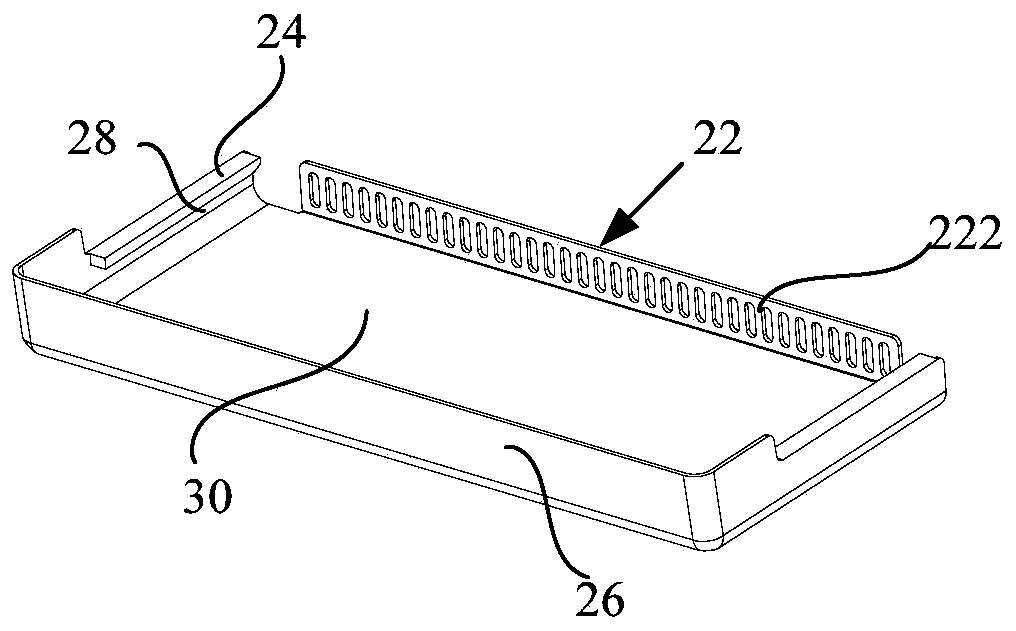

[0047] like figure 1 and figure 2 As shown, one embodiment of the present invention proposes a kind of bakeware structure, defines:

[0048] The structure of the baking pan includes: the main body of the baking pan 1, the burning pan 2, the burning pan 2 is set on one side of the main body 1 of the baking pan, a combustion cavity is formed between the burning pan 2 and the main body of the baking pan, and combustible materials can be placed in the combustion cavity , so that the combustibles burn in the combustion chamber, and the combustion pan 2 is detachably connected with the baking pan main body 1, so that the burning pan 2 and the baking pan main body 1 are cleaned by disassembling the burning pan 2 and the baking pan main body 1, so as to facilitate cleaning; It is beneficial to the cleaning of the grill pan structure; wherein, the grill pan main body 1 is provided with an air guide structure 12, and the air guide structure 12 communicates the combustion chamber with ...

Embodiment 2

[0054] like figure 1 As shown, in addition to the features of the above-mentioned embodiments, it is further defined:

[0055] The main body 1 of the baking pan includes: a main body of the baking pan 14 and an air guide structure 12. The air guiding structure 12 is arranged on one side of the main body of the baking pan 14 and communicates with the space above and below the main body 14 of the baking pan so that the gas in the combustion chamber can pass through The air guiding structure 12 enters from the space below the grill body 14 to the space above the grill body 14 to smoke and roast the ingredients on the grill body 14 .

[0056] Wherein, the air guide structure 12 can be provided on any side of the grill body 14 or the air guide structures 12 can be provided on multiple sides of the grill body 14 .

Embodiment 3

[0058] like figure 1 As shown, in addition to the features of any of the above-mentioned embodiments, it is further defined:

[0059] The baking pan body 14 includes: a holding portion 142 and a receiving portion 144. The holding portion 142 is formed by indenting from one side of the baking pan body 14 to the other side, so that the holding portion 142 can place food materials, and the holding portion 142 can store A certain volume of liquid substance, such as a mixture of water or oil, prevents the water or grease discharged from the food material from flowing out of the storage part 142 when the food is smoked and roasted, so as to facilitate centralized cleaning; the receiving part 144 is connected to the storage part 142 and extends outward. , when the baking pan structure is placed in an oven and other structures, the connection between the baking pan structure and the oven and other structures can be realized through the receiving part 144; , which is convenient for us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com