Injection system with far-end feeding function

An injection system and remote technology, applied in the field of injection systems for remote feeding, can solve problems such as unsuitable syringes, reduce size and design requirements, easily and quickly repeat feeding multiple times, and reduce repeated withdrawal and feeding. The effect of the number of times in the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

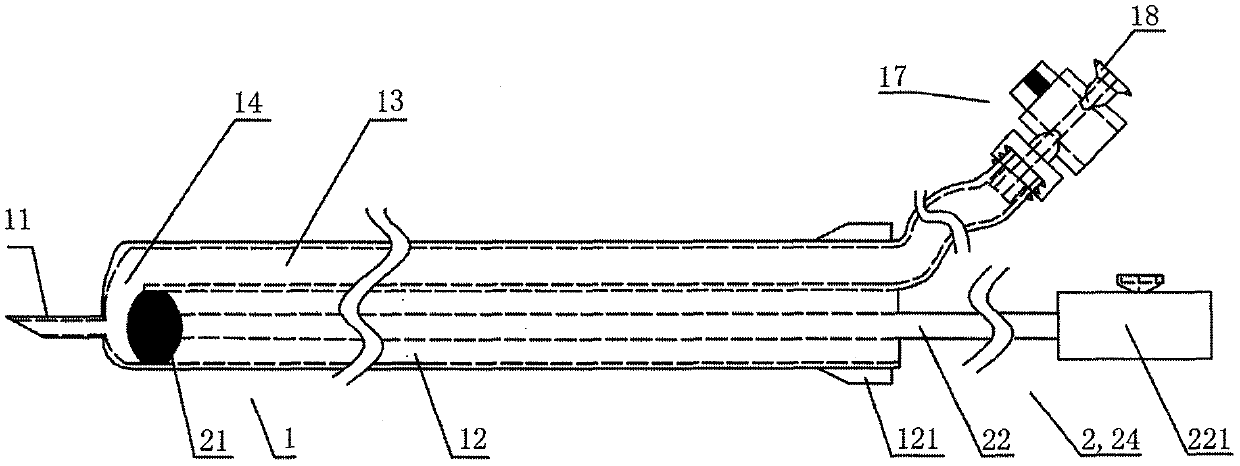

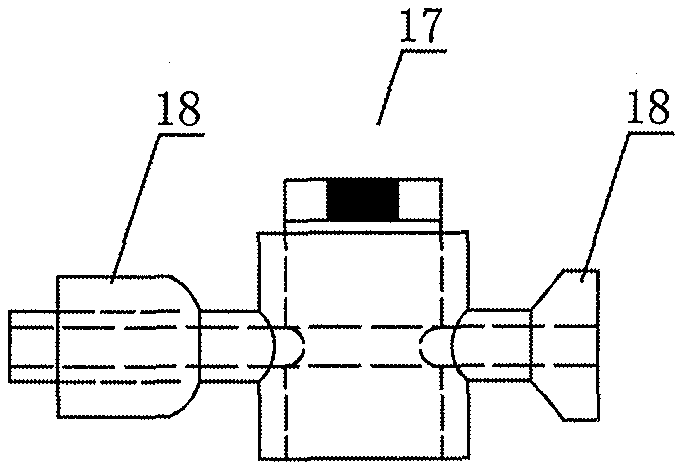

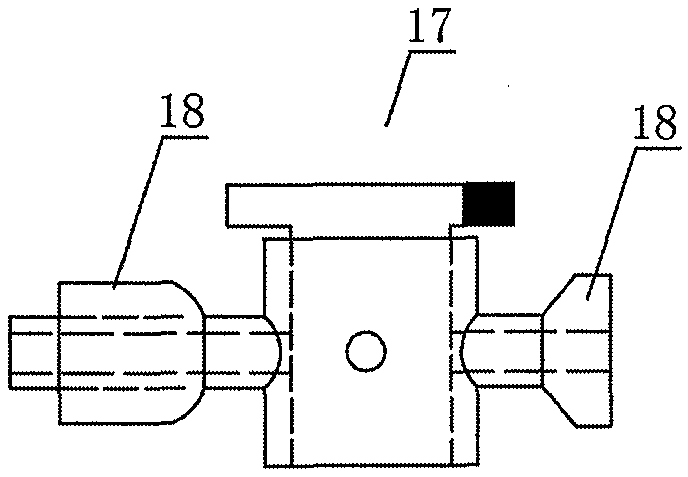

[0083] Such as Figure 1A As shown, the present application provides a remote-feeding injection system (hereinafter referred to as "the system"), which includes the injection assembly 1 including the feeding chamber 13 and the injection chamber 12, the pushing assembly 2 and the For the injection 3 in the feeding chamber 13, the remote end of the system is provided with an injection needle 11, the injection needle 11 is a hollow structure, and a backstop mechanism 17 and a communication port 14 are provided in the system, and the communication port 14 makes the feeding chamber 13 communicate with the inner cavity of the injection chamber 12 and the injection needle 11, when the injection 3 in the feeding chamber 13 is input into the injection chamber through the communication port 14 12, the pushing assembly 2 can move towards the proximal direction, so as to form a negative pressure state in the injection cavity 12 .

[0084] The pushing assembly 2 includes a power source 25 ...

Embodiment 2

[0107] Based on the first embodiment, the difference between the second embodiment and the first embodiment is that a second backstop mechanism 19 is further provided between the injection needle 11 and the communication port 14, so that the injection cavity 12 And the fluid in the injection needle 11 can only flow from the proximal end to the distal end, preventing external gas and human blood from flowing back into the injection cavity 12 from the injection needle 11, and finally endowing the system with any position in the body. Sufficient safety when feeding multiple times "in situ". The specific structure of the second backstop mechanism 19 can be designed similarly or identically to the various described backstop mechanism 17 described in Embodiment 1, and the structure that can be used for the second backstop mechanism 19 also includes a manual on-off valve The structure and the structure of the automatic on-off valve will be described below by enumerating the embodimen...

Embodiment 3

[0111] The difference between the present embodiment and the first embodiment is that the system is also provided with a monitoring mechanism 7, so as to enhance the effectiveness of the medical staff to use the system to judge the penetration depth of the injection needle at the position of the target lesion. The monitoring mechanism 7 can be implemented in various ways.

[0112] In one embodiment, as Figure 3A and Figure 3B As shown, the monitoring mechanism 7 is a tube body 71 in fluid communication with the injection cavity 12 and the injection needle 11, and a monitoring device that is slidingly sealed with the inner cavity of the tube body 71 is provided in the tube body 71. Piston 72. Further, on the basis of the first embodiment, the injection chamber 12 and the tube body 71 share one tube wall at the distal end part, and an opening 76 is arranged on the shared tube wall, and the tube body 71 and the tube body 71 The injection cavity 12 realizes fluid communicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com