Safety forging press for processing automobile parts

A kind of auto parts and safety technology, applied in the field of forging, can solve the problems of no emergency stop detection mechanism, high degree of danger, and the forging base cannot be lifted at any time, so as to achieve the effect of enhancing operational flexibility and isolating the degree of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0028] The 2 mentioned in the present invention (the model is TAD-WB60) can be obtained in the market or by private order.

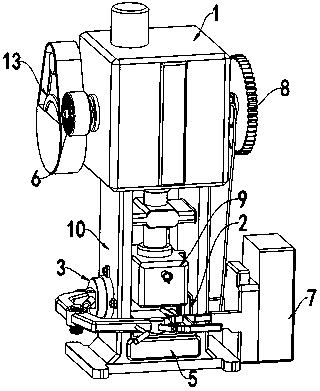

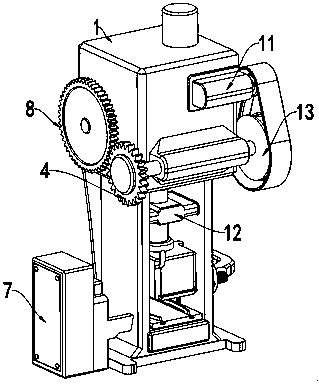

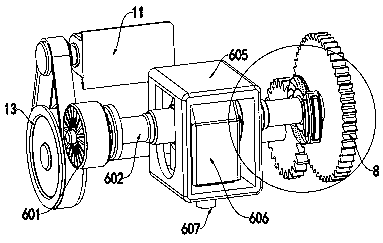

[0029] see Figure 1 to Figure 7 , an embodiment provided by the present invention: a safety forging press for auto parts processing, including a box body 1, two support walls 10 are arranged on the lower end surface of the box body 1, and the outer surface of one side of the support wall 10 is installed There is an auxiliary mechanical arm 3, wherein a switch box 7 is installed on one side of the other support wall 10, a human body detection mechanism 2 is installed on the inner wall of the other support wall 10, and a limit bar 12 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com