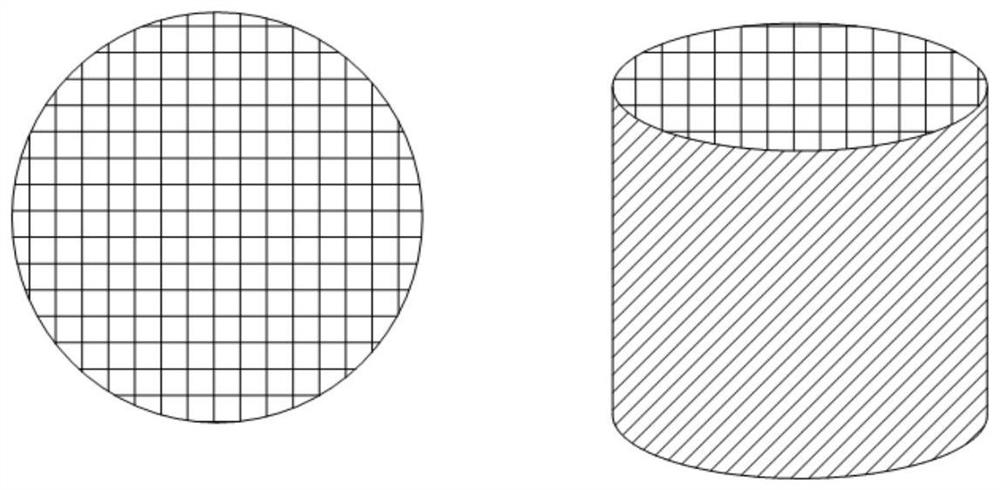

A kind of ceramic carrier with honeycomb structure and preparation method thereof

A ceramic carrier and honeycomb technology, which is applied in the field of cordierite honeycomb ceramic carrier, can solve the problems of reduced wall thickness, poor deformation resistance of mud blanks, and increased extrusion pressure, and achieves prevention of pore deformation, good ductility, The effect of good rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of ceramic carrier of honeycomb structure, the raw material composition of described ceramic carrier is:

[0030] Inorganic raw materials: talc 39wt%, kaolin 15wt%, α-alumina 14wt%, aluminum hydroxide 18wt%, quartz 14wt%;

[0031] Organic raw materials (mass percentage is calculated by adding the weight of inorganic raw materials): 7.5wt% composite cellulose ether, 6wt% polyalphaolefin, 0.5wt% tall oil, 2.5wt% potassium laurate; the composite cellulose ether is 30wt% Carboxymethyl cellulose and 70 wt% hydroxypropyl methyl cellulose are obtained through the modification of modifier 2-hydroxyethyl acrylate; the amount of modifier is 5 wt% based on the total amount of cellulose;

[0032] Deionized water (calculated based on the total weight of the ingredients): 20wt%;

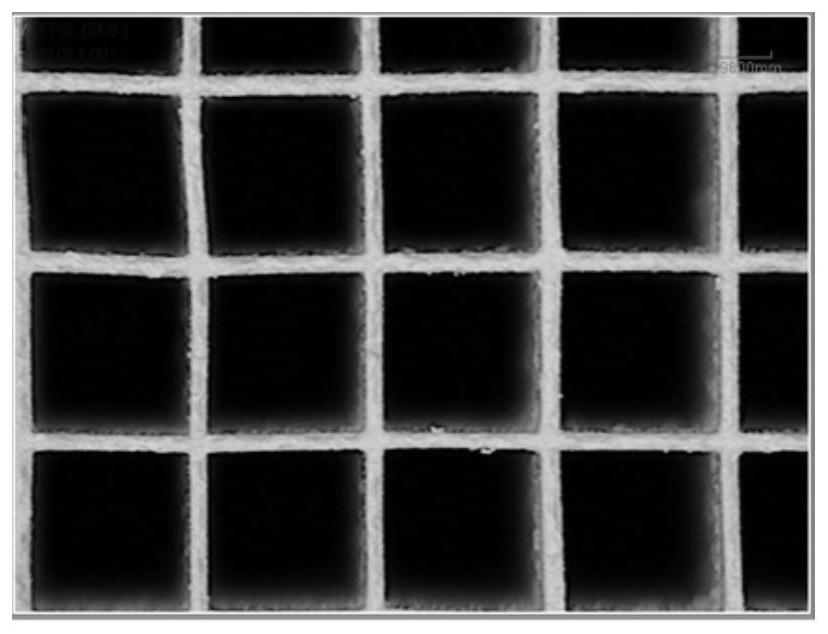

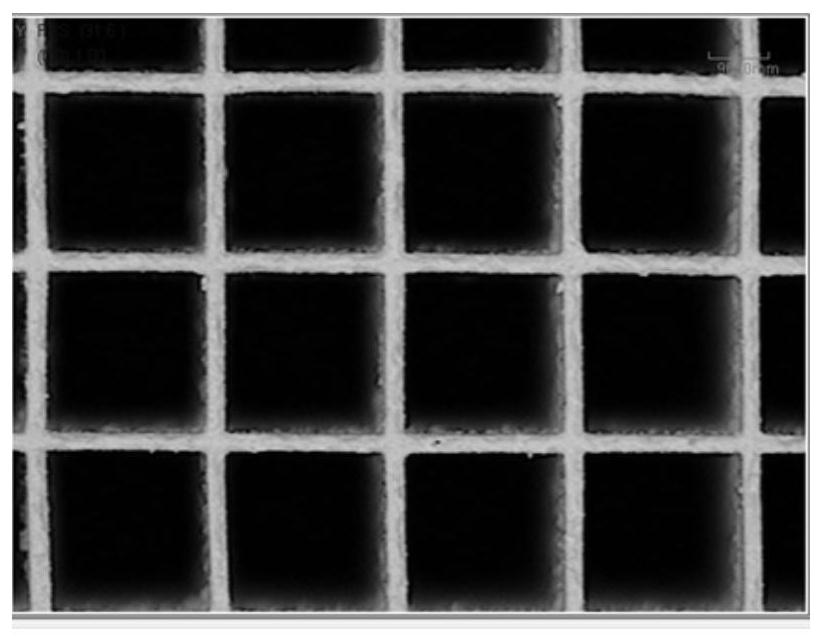

[0033] The above-mentioned raw materials are mixed into mud by a mixer, and then the mud is smelted, extruded, dried by microwave, and then fired at a high temperature to the honeycomb ceramic carri...

Embodiment 2

[0036] A kind of ceramic carrier of honeycomb structure, the raw material composition of described ceramic carrier is:

[0037] Inorganic raw materials: talc 39wt%, kaolin 15wt%, α-alumina 14wt%, aluminum hydroxide 18wt%, quartz 14wt%;

[0038] Organic raw materials (mass percentage is calculated by adding the weight of inorganic raw materials): 7.5wt% composite cellulose ether, 6wt% polyalphaolefin, 0.5wt% tall oil, 2.5wt% potassium laurate; the composite cellulose ether is 40wt% Carboxymethyl cellulose and 60 wt% hydroxypropyl methyl cellulose are obtained through the modification of modifier 2-hydroxyethyl acrylate; the amount of modifier is based on the total amount of cellulose plus 5 wt%;

[0039] Deionized water (calculated based on the total weight of the ingredients): 20wt%;

[0040] The above-mentioned raw materials are mixed into mud by a mixer, and then the mud is smelted, extruded, dried by microwave, and then fired at a high temperature to the honeycomb ceramic ...

Embodiment 3

[0043] A kind of ceramic carrier of honeycomb structure, the raw material composition of described ceramic carrier is:

[0044] Inorganic raw materials: talc 39wt%, kaolin 15wt%, α-alumina 14wt%, aluminum hydroxide 18wt%, quartz 14wt%;

[0045] Organic raw materials (mass percentage is calculated by adding the weight of inorganic raw materials): 7.5wt% of composite cellulose ether, 6wt% of polyalphaolefin, 0.5wt% of tall oil, 2.5wt% of potassium laurate; the composite cellulose ether is 50wt% Carboxymethyl cellulose and 50 wt% hydroxypropyl methyl cellulose are obtained through the modification of modifier 2-hydroxyethyl acrylate; the amount of modifier is based on the total amount of cellulose plus 5 wt%;

[0046] Deionized water (calculated based on the total weight of the ingredients): 20wt%;

[0047] The above-mentioned raw materials are mixed into mud by a mixer, and then the mud is smelted, extruded, dried by microwave, and then fired at a high temperature to the honeyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com