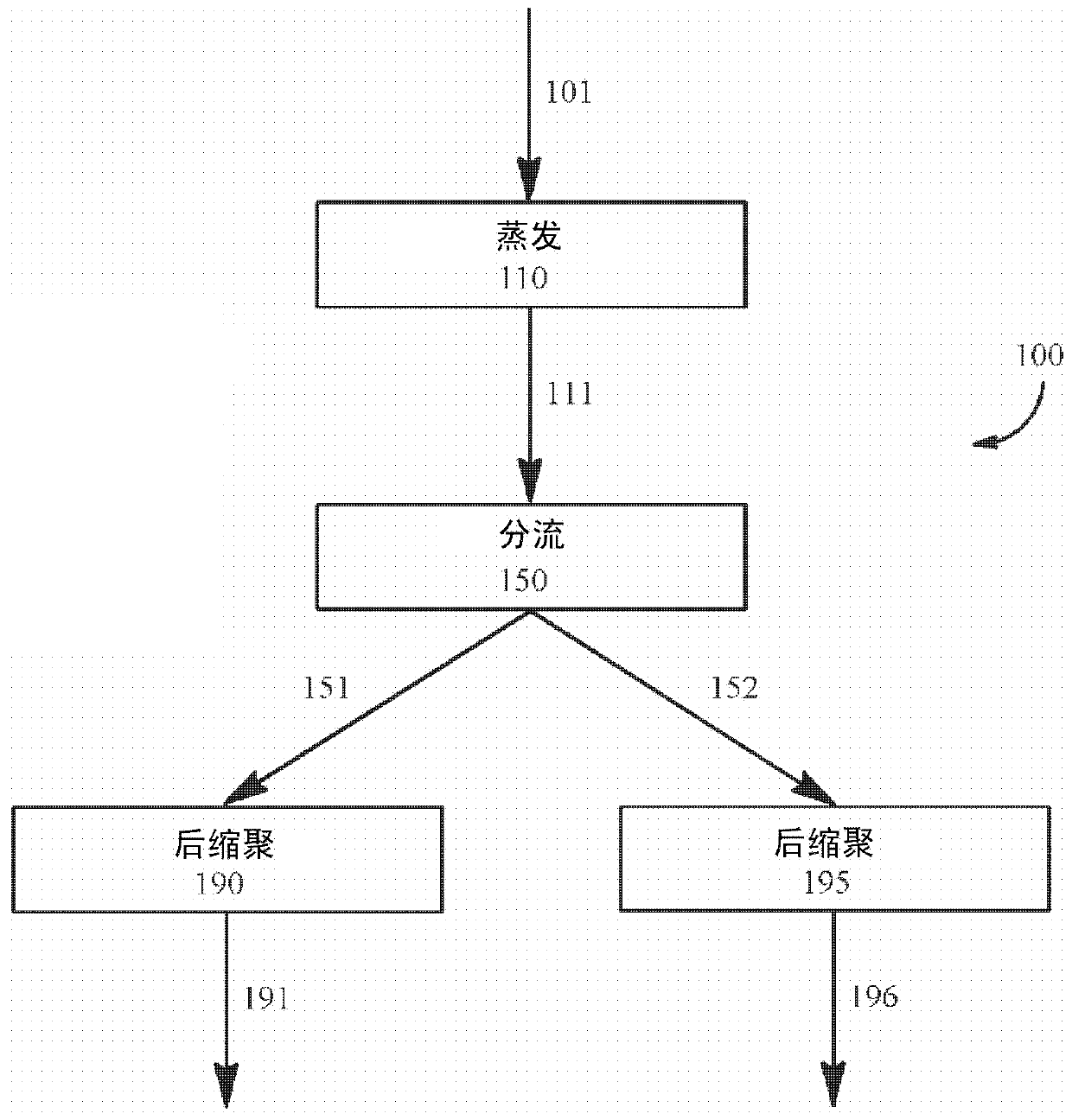

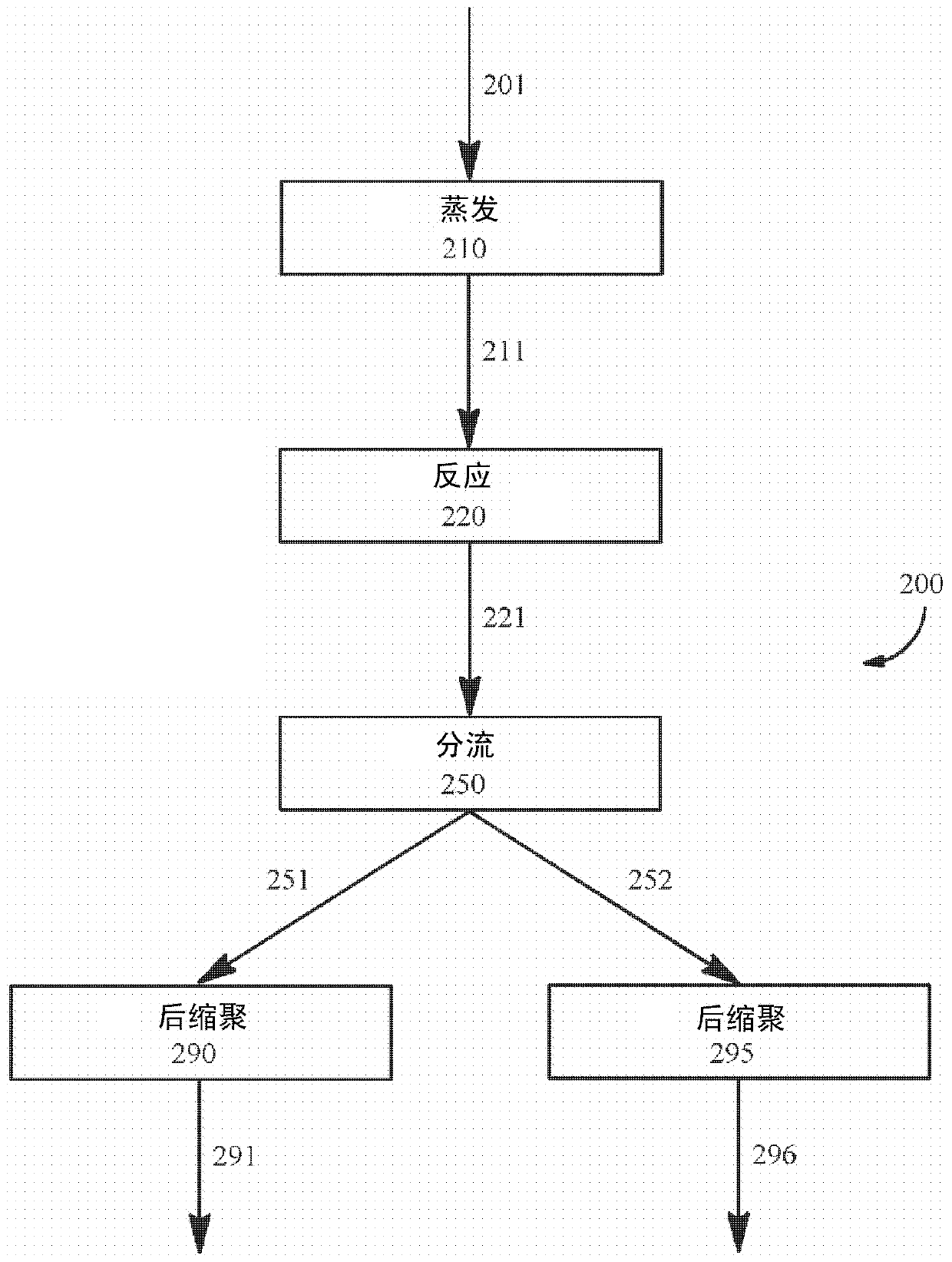

Polyamide synthesis including multiple back-ends

A technology of polyamide and post-polycondensation, which is applied in the direction of distillation separation, separation methods, chemical instruments and methods, etc., can solve problems such as limited size, and achieve the effect of avoiding capacity bottlenecks, economical equipment costs, and economical costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0082] The present invention can be better understood by referring to the following examples provided by way of example. The present invention is not limited to the examples given herein.

[0083] Throughout the examples, X represents the same cost. Throughout the examples, Z represents the same cost.

Embodiment 3a

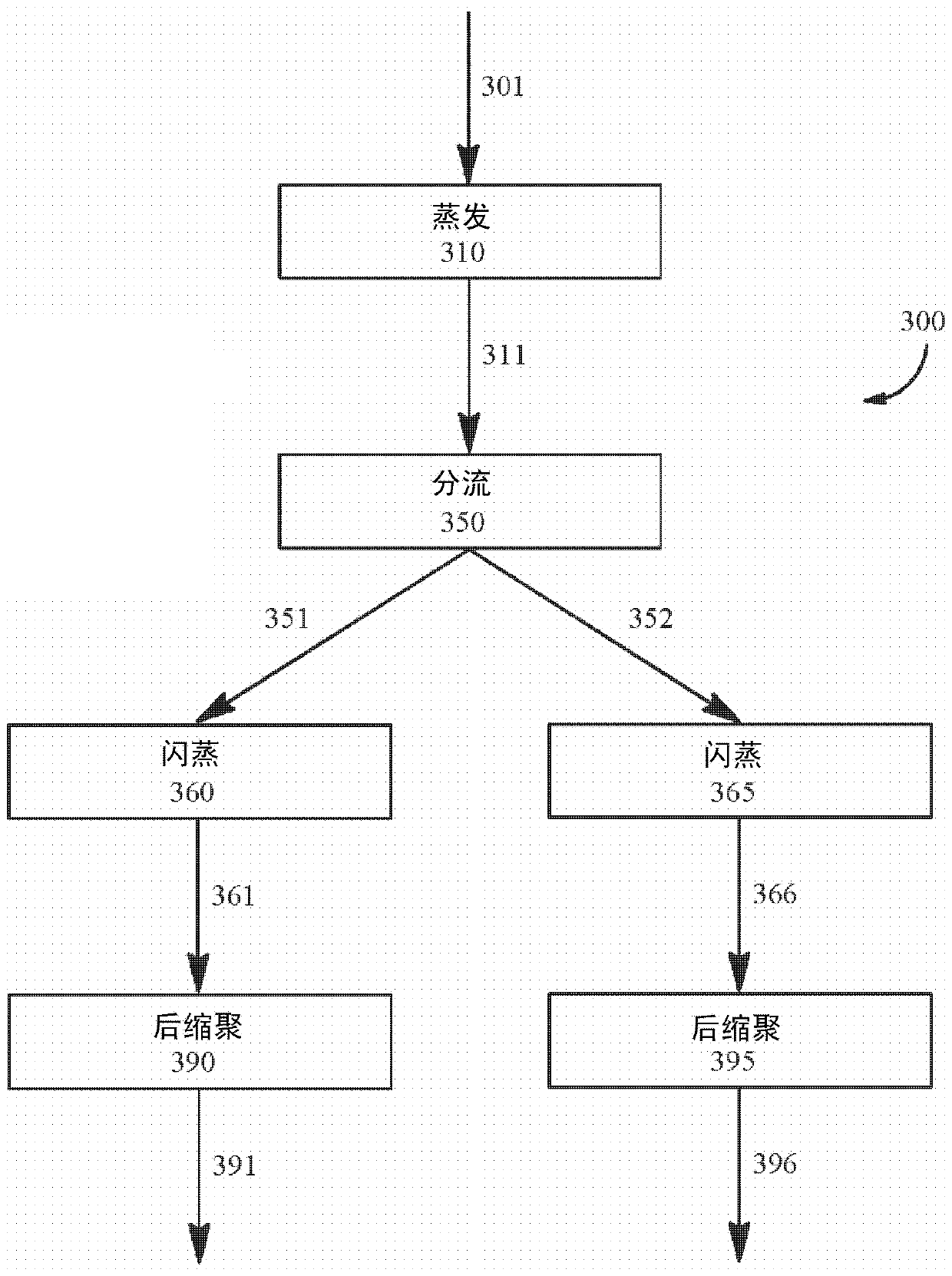

[0122] Example 3a. Continuous process with multiple finishers.

[0123] Following the method described in Example 1a, a system including a unit of approximately three times the size and processing three times the flow rate was used, similar to Example 1c. However, instead of the single finisher of Example 1c, two parallel finishers were used, and the stream from the flasher was split evenly between the finishers.

[0124] The salt pond delivers materials to the evaporator at about 315L / min, has a volume of about 12,000L, costs about 3*Z to purchase and build into the system, and costs about 3*X / h to run. The evaporator delivers material into the reactor at about 225L / min, has a volume of about 12,000L, costs about 9*Z to purchase and build into the system, and costs about 12*X / h to run. The reactor delivers material to the flash evaporator at about 180 L / min, has a volume of about 4,500 L, costs about 15*Z to purchase and build into the system, and costs about 12*X / h to operate. ...

Embodiment 3b

[0126] Example 3b. Continuous process with multiple finishers.

[0127] The method of Example 3 was followed, except that one finisher was configured to produce a polymer having a relative viscosity of about 60, and the other finishers were configured to produce a polymer with a relative viscosity of about 50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com