A gob-side digging method for piers without blasting and top cutting

A technology without blasting and piers, applied in the direction of earthwork drilling, pillars/supports, temporary shields, etc., can solve the problems of shortened service life of mines, low coal recovery rate, and increased width of isolated coal pillars, etc., to achieve reduction Effects of roof sinking rotation duration, reduction of sinking amount and movement time, and reduction of roadway surrounding rock deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

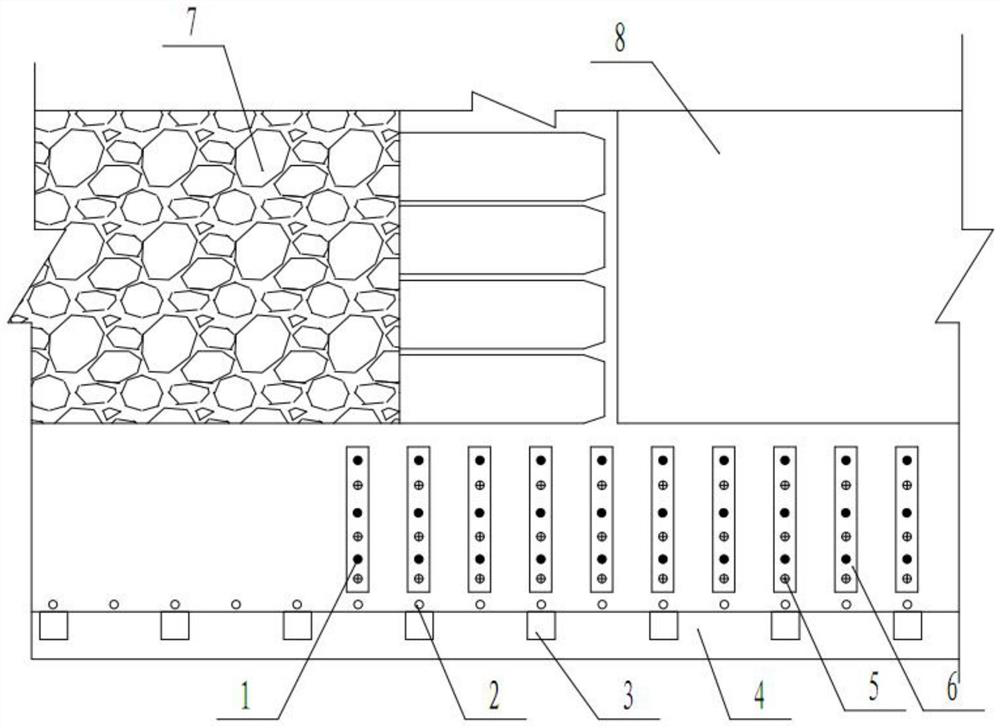

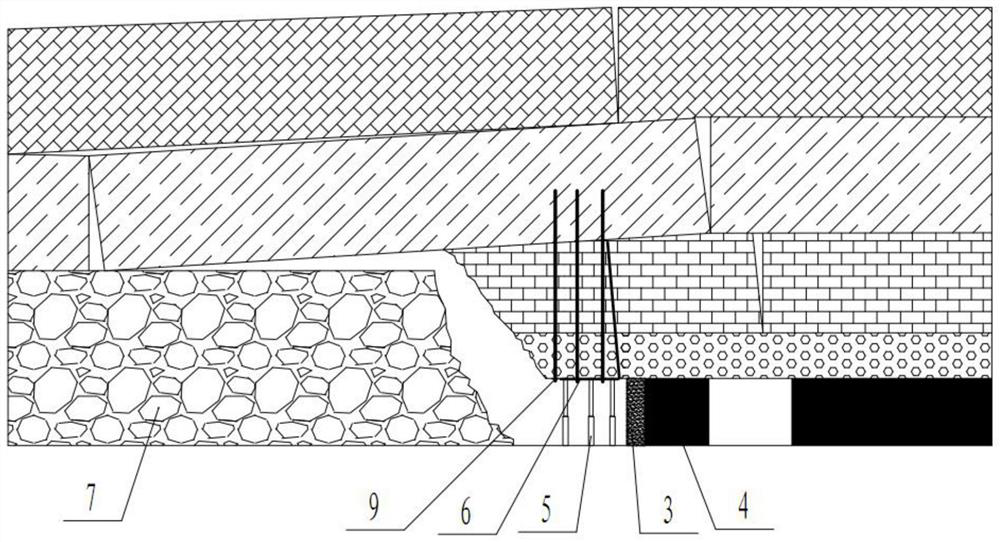

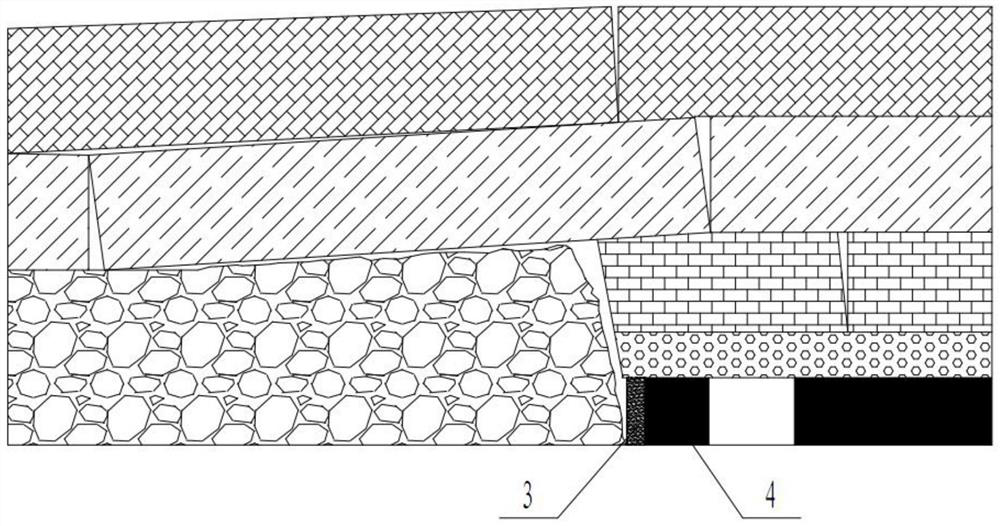

[0020] Embodiment 1: as Figure 1-4 Shown, a kind of pier pillar non-blasting top cutting method for gob-side entry, the method includes the following steps:

[0021] 1. Construction slit hole 2

[0022] The location of the top-cutting and slotting hole beside the roadway should be selected on the 4th side of the coal pillar along the channel, and the drilling hole is about 0.5~0.8m away from the side of the small coal pillar. The radial direction of the slit hole 2 forms an angle α with the top plate, such as Figure 4 As shown, the depth H is determined according to the broken expansion coefficient of the roof strata; in order to make the goaf roof collapse smoothly after cutting and reduce the friction effect on the roadway roof during the collapse process, the roof cutting angle α needs to be determined according to the roof cutting layer , the reasonable cutting depth is 3~5 times of the mining height of the working face;

[0023] 2. Arrangement of piers 3

[0024] Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com