Periostracum cicada shelling type rectangular jacking pipe receiving construction method

A rectangular pipe jacking and construction method technology, applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve problems such as waterproofing, achieve the effects of ensuring efficiency, solving waterproofing problems, and improving deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

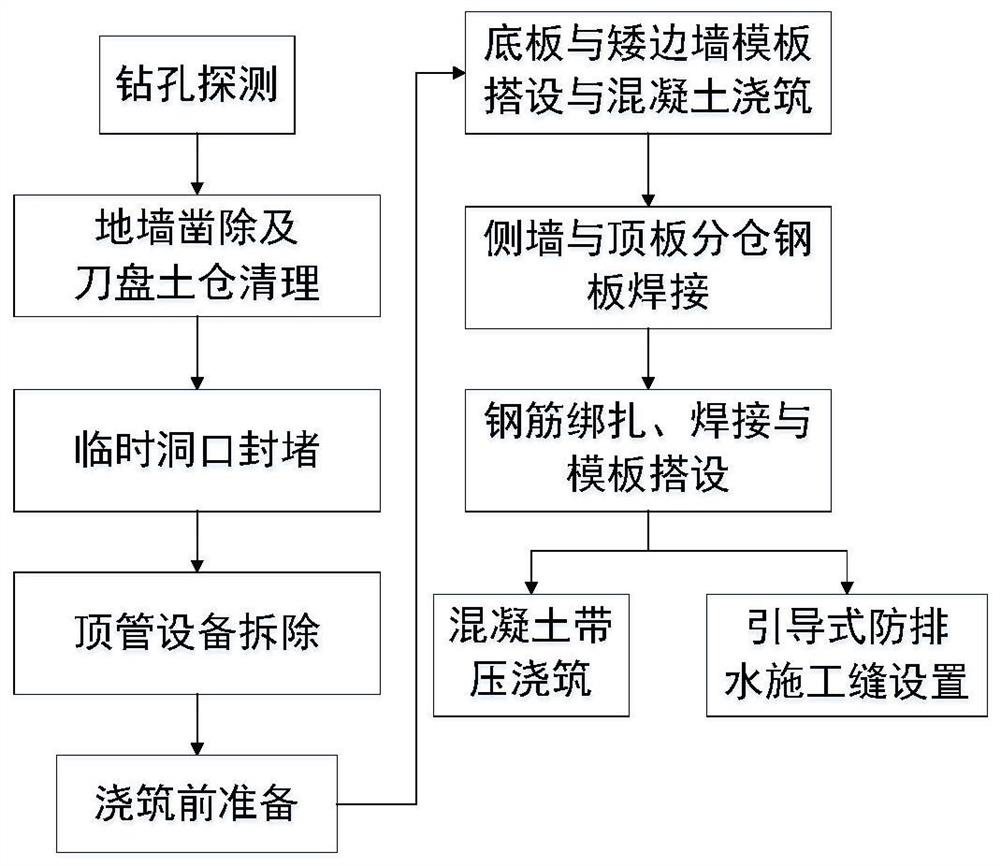

Method used

Image

Examples

Embodiment Construction

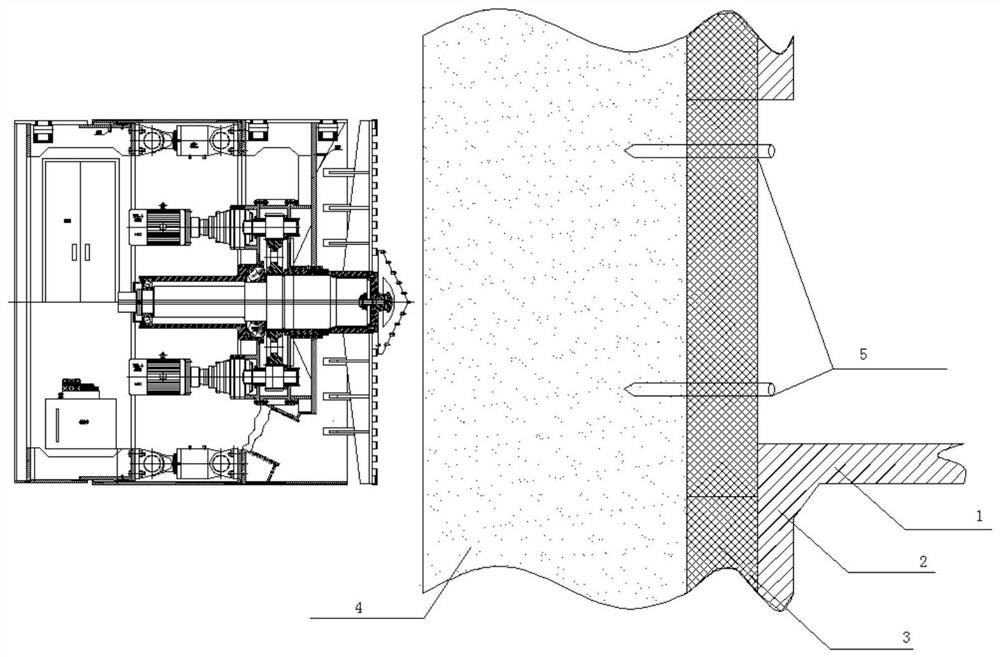

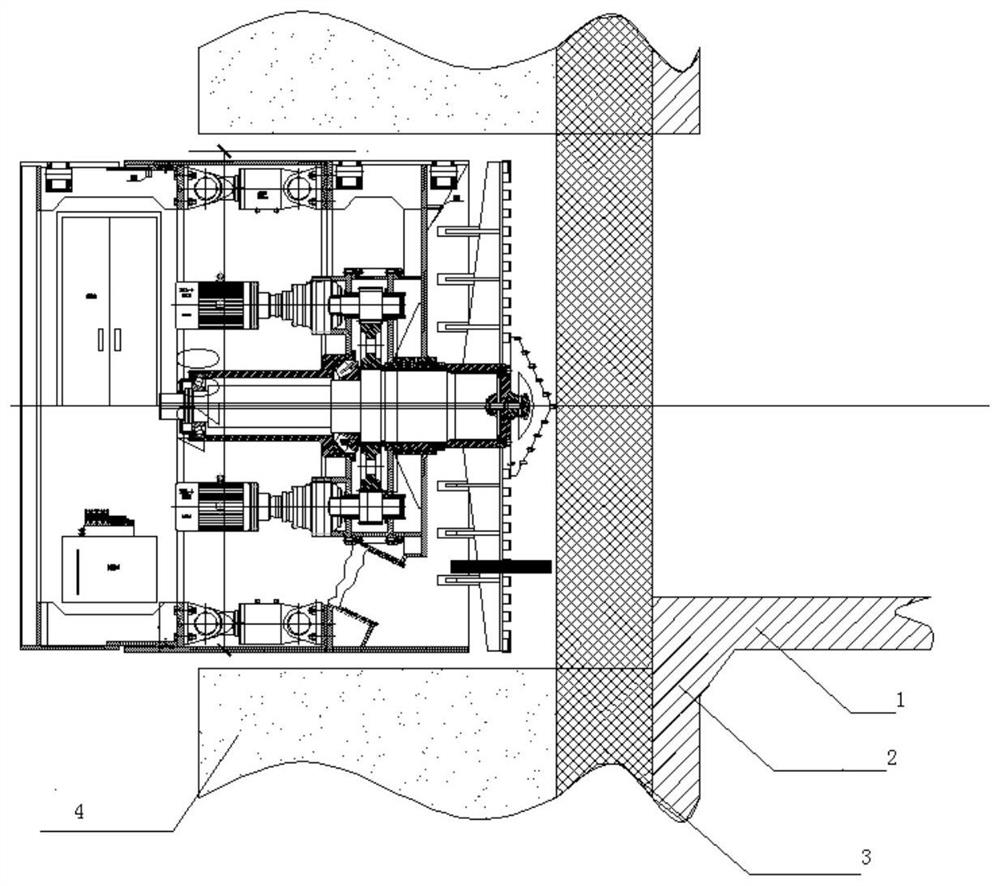

[0049]In the accompanying drawings, the station middle plate 1, station side wall 2, (enclosure) ground wall 3, receiving reinforcement section 4, detection hole 5, temporary hole sealing 6, pre-embedded steel ring edge / ground wall excavation range 7, Pipe jacking machine shell 8, hole door gap sealing wall layer 9 (the gap between the pipe jacking machine shell 8 and the underground continuous wall is sealed with bricks first, and then a layer of quick cement is sealed on the outside of the brick wall), (made of steel) Jacking pipe shell 10, (quick) cement slurry 11, cast-in-place concrete lining 12 (subsequent construction), prefabricated segment 13, compartment steel plate 14, sleeved rubber waterstop 15, bottom plate 12a, left and right short sides Wall 12b, left and right side walls 12c, roof 12d;

[0050] The main underground diaphragm wall 16, the station roof 17 (that is, the roof surface of the main structure), the pump pipe 18, (after the pipe jacking construction is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com