Device and method for measuring response time of MEMS infrared detector

An infrared detector and response time technology, applied in the field of infrared detectors, can solve the problem that the time-consuming work of the chopper cannot be ruled out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

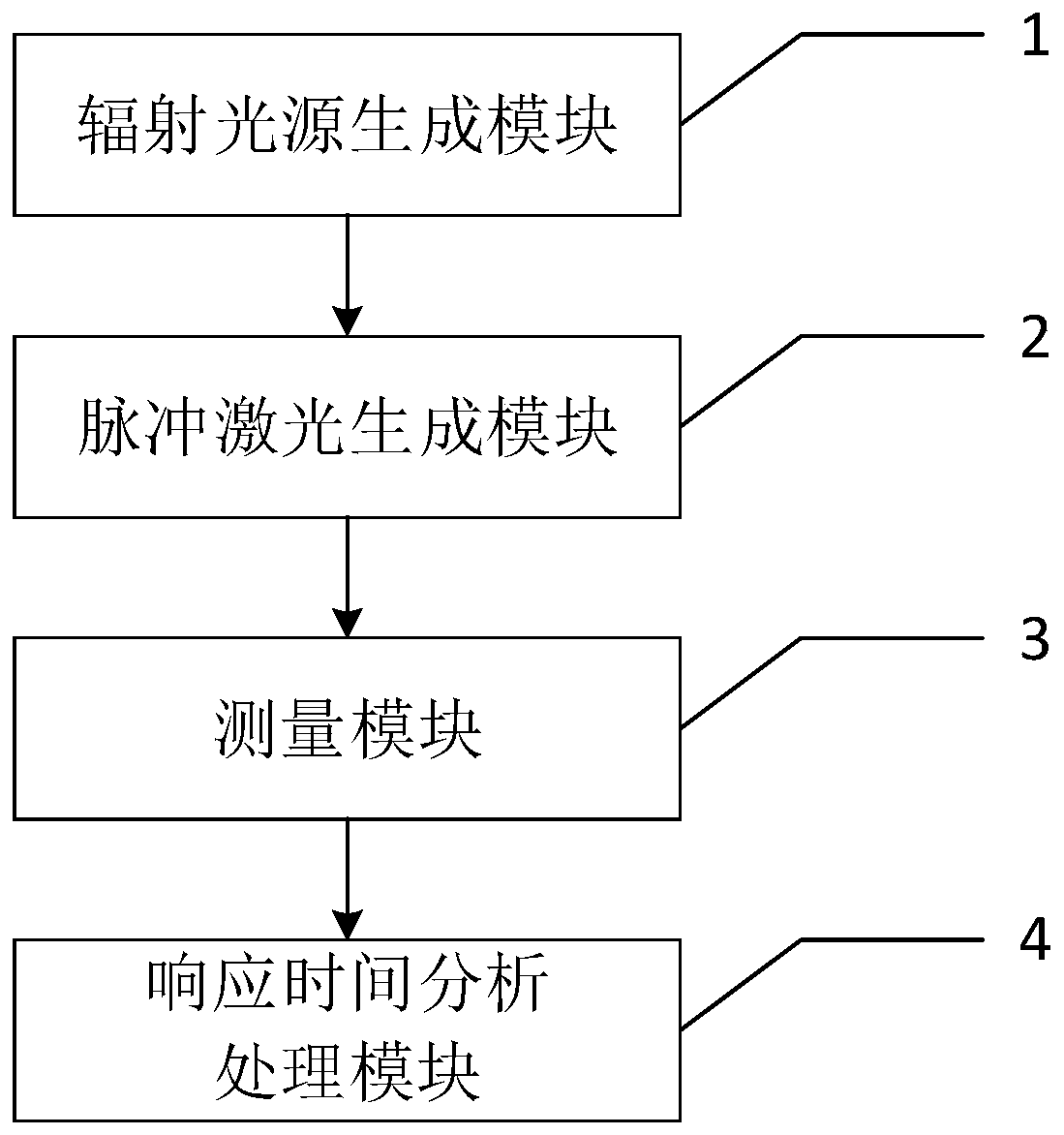

[0033] An embodiment of the present invention provides a device for measuring the response time of a MEMS infrared detector, such as figure 1 As shown, it includes: a radiation source generation module 1, used to generate a radiation source; a pulsed laser generation module 2, used to generate a pulsed laser according to the radiation source, and input it to the MEMS infrared detector; a measurement module 3, used to measure the MEMS infrared The first voltage value and the second voltage value of the detector under different powers of the pulsed laser; the response time analysis and processing module 4 is used to measure the response time of the MEMS infrared detector according to the first voltage value and the second voltage value.

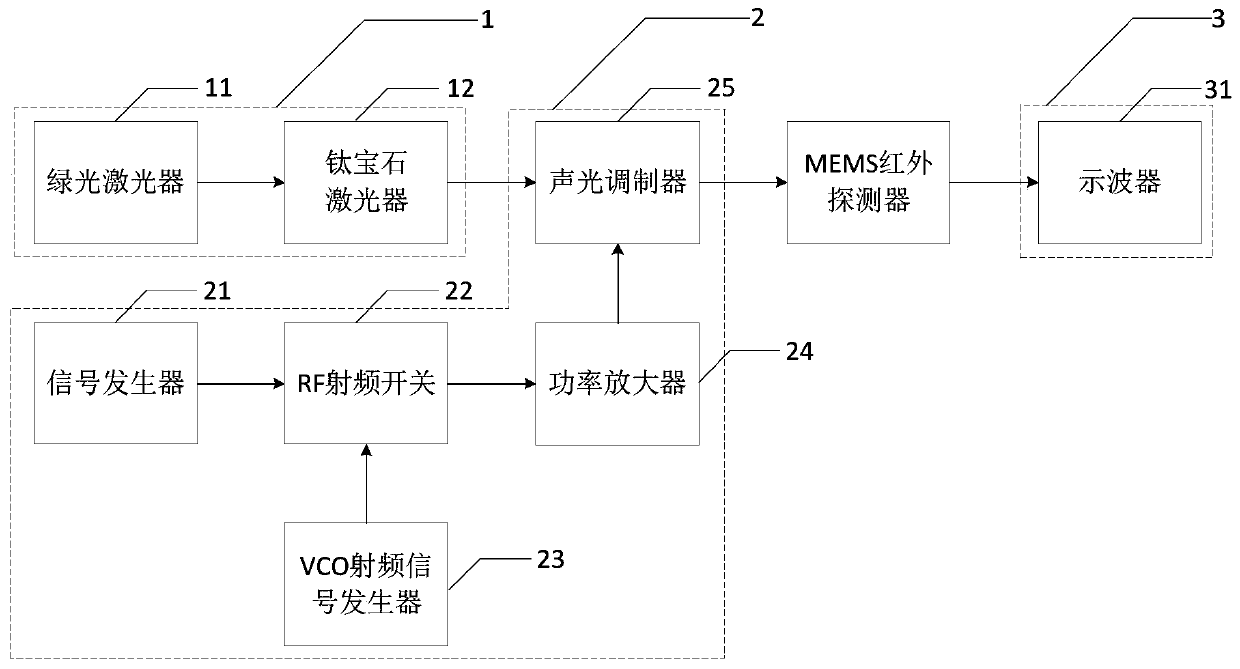

[0034] In an alternative embodiment, such as figure 2As shown, the above-mentioned radiation source generation module 1 includes: a green laser 11 and a Ti:sapphire laser 12, wherein the green laser 11 is used to emit the first outgoing light,...

Embodiment 2

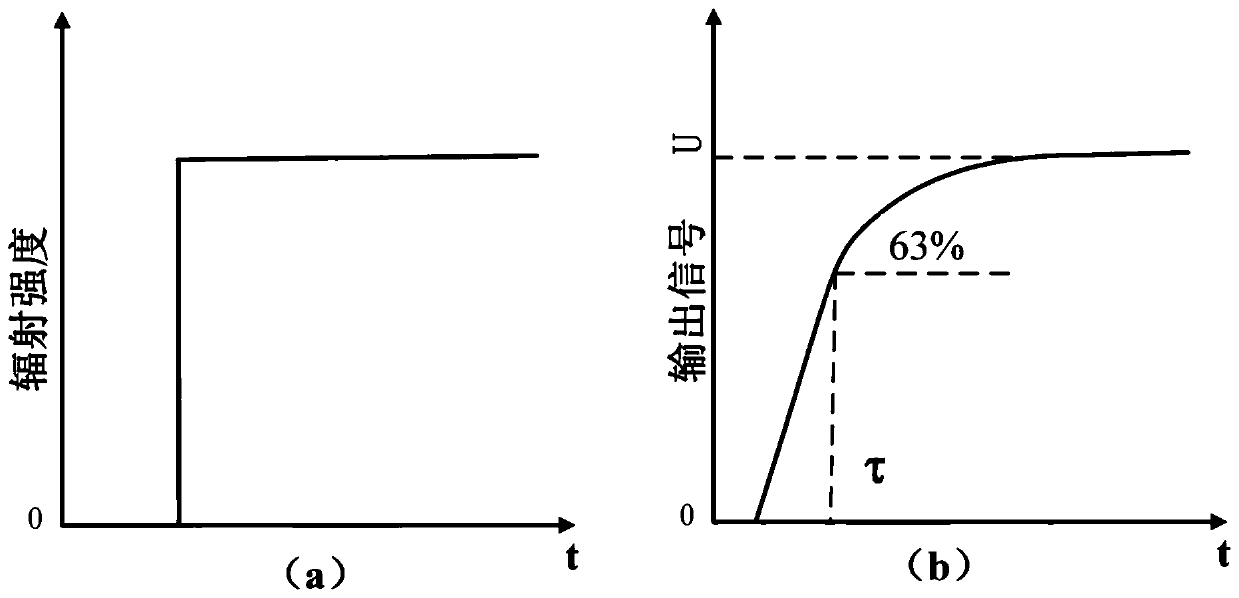

[0053] The embodiment of the present invention provides a method for measuring the response time of a MEMS infrared detector, which is applied to the above-mentioned device for measuring the response time of a MEMS infrared detector, such as Figure 4 shown, including the following steps:

[0054] Step S1: Generate a radiation source by the radiation source generation module 1 .

[0055] The above-mentioned radiation source generating module 1 includes: a green laser 11 and a Ti:sapphire laser 12, the green laser with a wavelength of 532nm is output by the green laser 11 as the pumping source of the Ti:sapphire laser 12, and the Ti:sapphire laser 12 pumps the green laser A radiation source with an output wavelength of 795nm.

[0056] Step S2: Generate pulsed laser light according to the radiation source through the pulsed laser generating module 2, and input it to the MEMS infrared detector.

[0057] The above-mentioned pulsed laser generating module 2 includes: signal gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com