A non-rigid material hexahedron precision automatic processing technology and system

An automatic processing and hexahedron technology, applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of high labor dependence, unfavorable production cost saving, and high labor intensity of workers, so as to prevent damage and solve the problem of equipment use efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

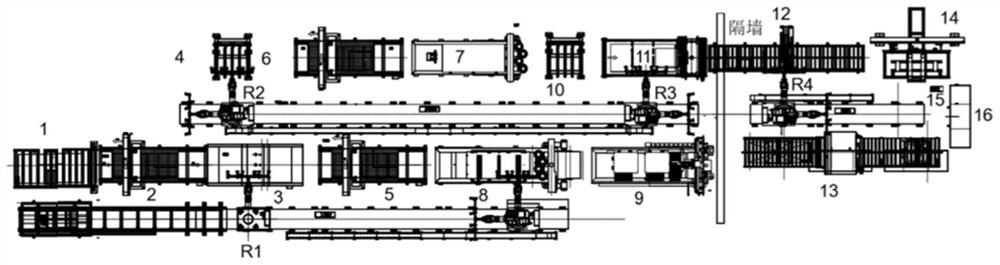

Embodiment 1

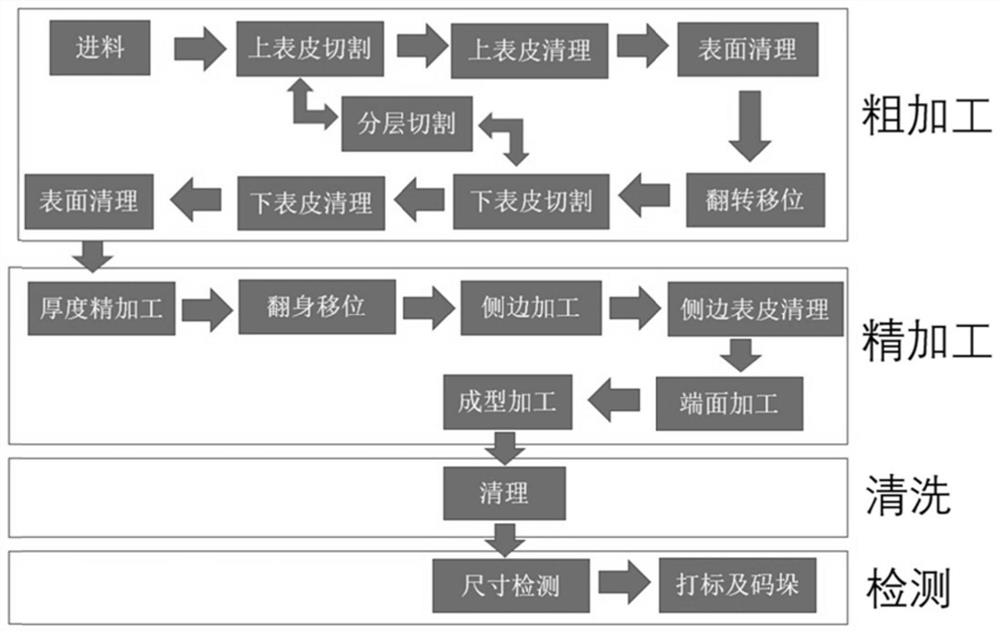

[0083] The detailed description of each specific process is as follows, and the flow chart can be found in figure 2 :

[0084] The rough processing stage of foam board includes the following processes:

[0085] 1. In the "feeding" process, the raw materials (workpieces) are transported here through the transmission system. During the feeding process, the length and thickness of the raw materials are initially detected, and unqualified raw materials are removed in time to avoid unqualified finished products.

[0086] 2. The "upper skin cutting" process is completed by the first CNC sawing machine (NC gantry band sawing machine), which is processed according to the thickness required by the finished foam board. The CNC sawing machine needs to be designed according to the automatic remote control system and has remote control functions.

[0087] 3. The "upper skin cleaning" process is completed by the first robot R1, which sends the cut upper skin to the waste trolley through t...

Embodiment 2

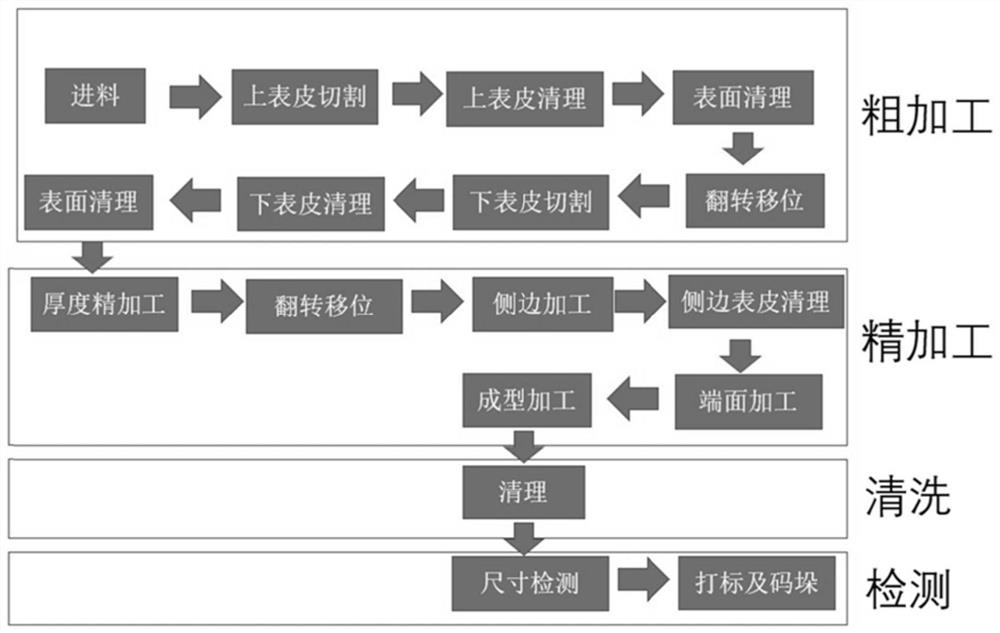

[0138] The detailed description of each specific process is as follows, and the flow chart can be found in image 3 :

[0139] The rough processing stage of foam board includes the following processes:

[0140] 1. In the "feeding" process, the raw materials are transported here through the transmission system. During the feeding process, the length and thickness of the raw materials are inspected, and unqualified raw materials are removed in time to avoid unqualified finished products.

[0141] 2. The "upper skin cutting" process is completed by the first CNC sawing machine, which is processed according to the thickness required by the finished foam board. The sawing machine needs to be designed according to the automatic remote control system and has remote control functions.

[0142] 3. The "upper skin cleaning" process is completed by the first robot R1, which sends the cut upper skin to the waste trolley through the gripper.

[0143] 4. The "surface cleaning" process is ...

Embodiment 3

[0164] The detailed description of each specific process is as follows, and the flow chart can be found in Figure 4 :

[0165] The rough processing stage of foam board includes the following processes:

[0166]1. In the "feeding" process, the raw materials are transported here through the transmission system. During the feeding process, the length and thickness of the raw materials are inspected, and unqualified raw materials are removed in time to avoid unqualified finished products.

[0167] 2. The "upper skin cutting" process is completed by the first CNC sawing machine, which is processed according to the thickness required by the finished foam board. The sawing machine needs to be designed according to the automatic remote control system and has remote control functions.

[0168] 3. The "upper skin cleaning" process is completed by the first robot R1, which sends the cut upper skin to the waste trolley through the gripper.

[0169] 4. The "surface cleaning" process is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com