Grinding equipment for motorcycle parts

A technology for motorcycles and accessories, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problem of low efficiency of plate grinding, and achieve the effect of reducing labor intensity and improving grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

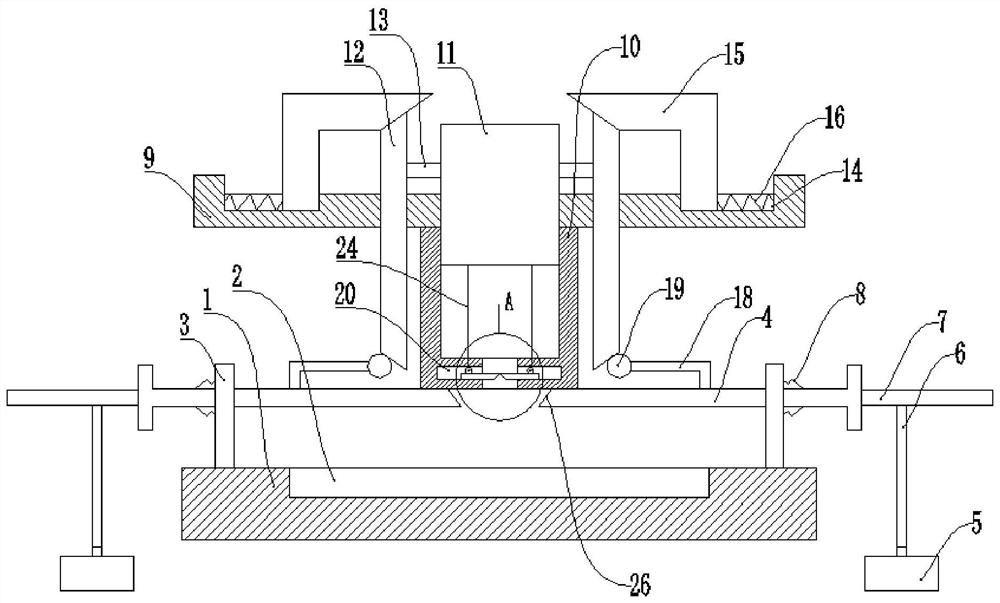

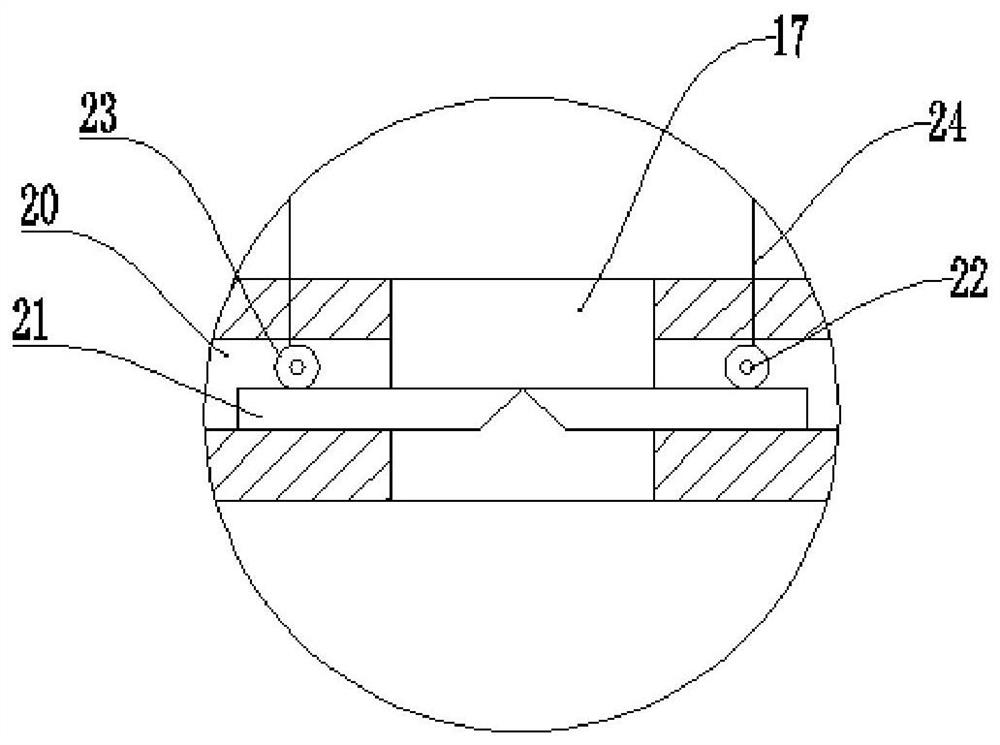

[0031] Basic as attached figure 1 And attached figure 2 Shown: The grinding equipment for motorcycle accessories, including the machine base, on which a workbench 1 is fixed, and the middle part of the workbench 1 is provided with a groove 2, and the plate is placed in the groove 2, through the groove 2 pairs The plate is limited, and the thickness of the plate is greater than that of the workbench 1 .

[0032] On the workbench 1, a support platform 3 is fixed symmetrically with the groove 2 as the center, and a polishing block 4 is connected to the support platform 3 by sliding horizontally, and a first spring 8 is fixed between the polishing block 4 and the support platform 3; A power mechanism for driving the grinding block 4 to reciprocate laterally and a dust removal mechanism for removing dust on the plate are arranged on the top. In this embodiment, the power mechanism includes a motor 5 fixedly connected to the machine base and a rotating shaft 6 fixedly connected t...

Embodiment 2

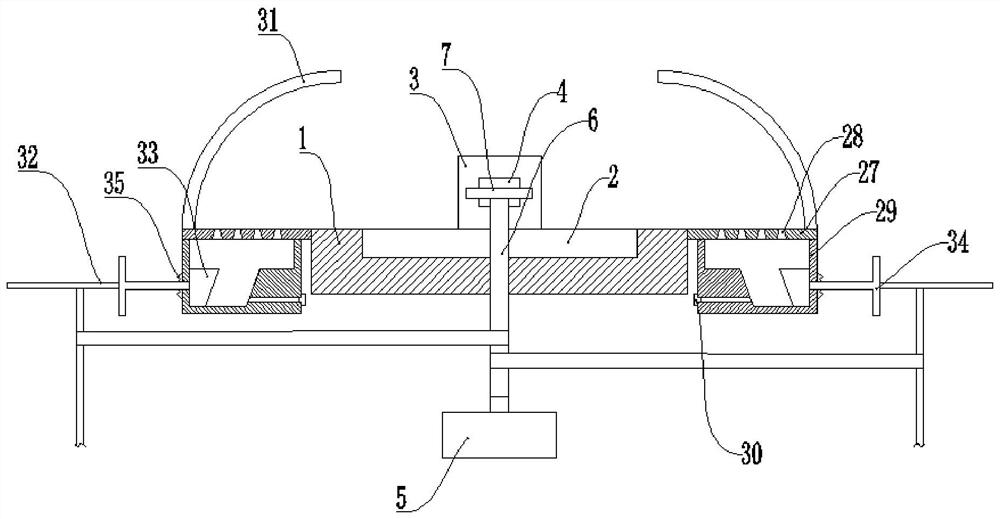

[0043] Basic as attached image 3 As shown: the structure and implementation of the second embodiment are basically the same as that of the first embodiment, the difference is that: both sides of the workbench 1 are fixedly connected with a collection plate 27, and the collection plate 27 has a number of collection holes 28. A collection box 29 is fixedly connected to the bottom of the collection plate 27, and a material port is provided on the side wall of the collection box 29, and a sealing cover 30 is threadedly connected to the material port. On the side of the collecting plate 27 far away from the workbench 1, an arc-shaped plate 31 facing the direction of the workbench 1 is fixed. The arc-shaped plate 31 can block and guide the dust, so that the dust can move towards the direction of the collecting plate 27 .

[0044] An auxiliary shaft is rotatably connected to the base, and a belt is sleeved between the auxiliary shaft and the rotating shaft 6; a second cam 32 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com