A kind of diamond metal bond product and its integral molding manufacturing method and application

A technology of metal bonding agent and manufacturing method, which is applied in the direction of manufacturing tools, metal processing equipment, grinding devices, etc., can solve the problems that the grinding efficiency of diamond abrasives needs to be improved, and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Roughen the area where the cutter head needs to be set on the metal base part (the material is specifically 45# steel) (the specific method is barbs) to obtain a roughened metal base part with a roughness of 3mm;

[0046] Put the silane coupling agent KH560 and diamond-metal powder in a mixer, mix for 1 hour at room temperature and normal air pressure for surface modification treatment, and then granulate to obtain spherical particles, that is, surface-modified diamond metal particles ; Wherein, the silane coupling agent KH560 is 5% of the diamond-metal powder mass, and the diamond-metal powder is a mixture of alloy powder and diamond, and the mass ratio of the alloy powder to diamond is 9:1; the particle size of diamond is 10~ 800 mesh; the composition of the alloy powder is iron 32wt.%, copper 15wt.%, nickel 5wt.%, tin 5wt.%, cobalt 15wt.%, manganese 3wt.%, silicon 2wt.%, chromium 8wt.% and tungsten carbide 15wt.%, the particle size of the alloy powder is 60-70 mesh; ...

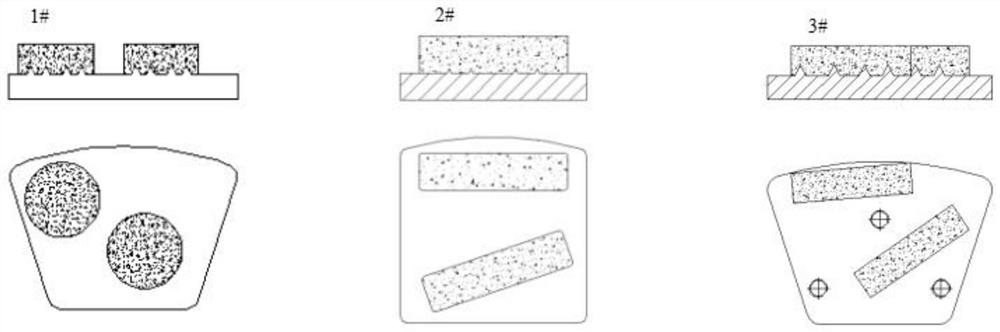

Embodiment 2

[0049] The method for preparing the diamond metal bond article with reference to embodiment 1, the difference is that the shape of the metal base part and the cutter head is different from that of embodiment 1; the gained diamond metal bond article is marked as 2# product, wherein, it comprises A rectangular cutter head, the length of the cutter head is 40mm, the width is 10mm, and the height is 10mm.

Embodiment 3

[0051] According to the method for embodiment 1, the diamond metal bond product is prepared, and the difference is that the shape of the metal matrix part and the cutter head is different from that of embodiment 1; the gained diamond metal bond product is denoted as 3# product, wherein, including two A rectangular cutter head, the length of the cutter head is 40mm, the width is 10mm, and the height is 10mm.

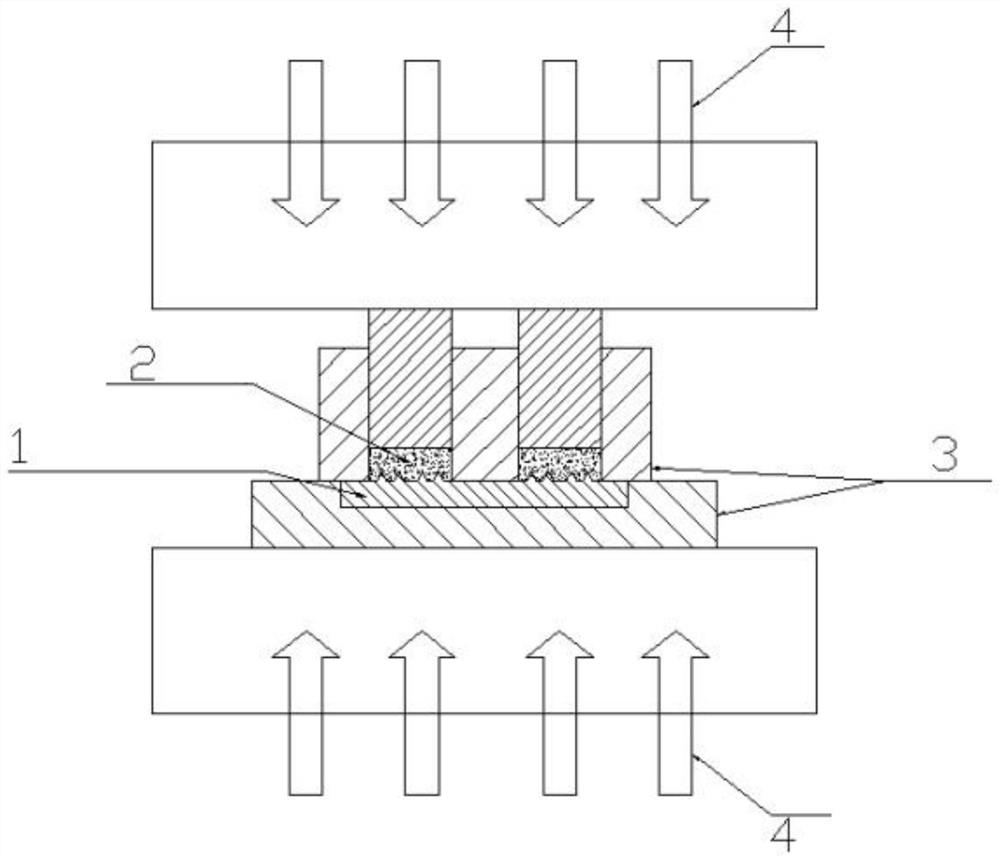

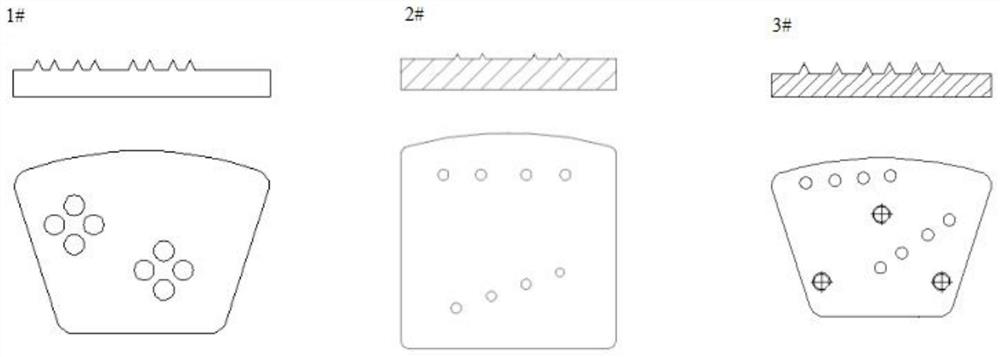

[0052] figure 2 It is a schematic diagram of the roughened metal matrix part in embodiments 1-3, image 3 It is a schematic diagram of a diamond metal bond product in Examples 1 to 3, Figure 4 It is the physical figure of the diamond metal bond product in Examples 1 to 3; Figure 2~4 Among them, 1# corresponds to embodiment 1, and 2# corresponds to embodiment 2, and 3# corresponds to embodiment 3; figure 2 and 3 In each example, the roughened metal matrix piece and the diamond-metal bonded piece are given a front view and a top view, respectively. like figure 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com