A Composite Geotechnical Drainage Network Automatic Forming Device

An automatic forming and composite geotechnical technology, which is applied in the field of drainage network, can solve the problems of poor precision, increasing the number of defective products, cumbersome work, etc., and achieve the effects of high product quality, labor saving, and firm cementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

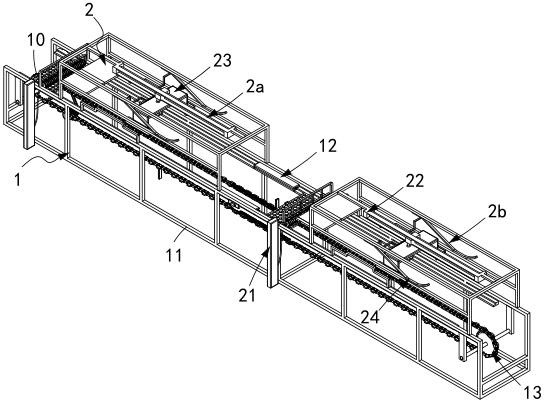

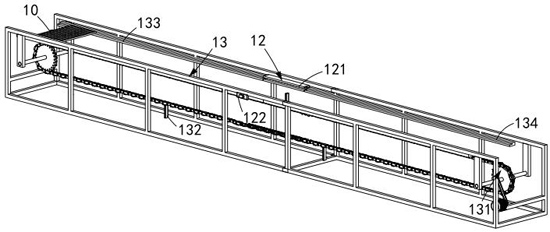

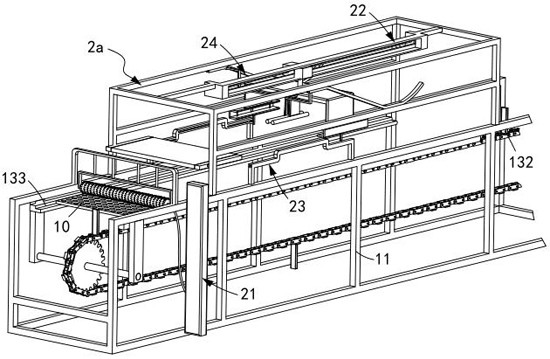

[0063] Such as figure 1 , figure 2 and image 3 As shown, a composite geotechnical drainage net automatic forming device, including:

[0064] Drainage net loading mechanism 1, said drainage net loading mechanism 1 includes a frame 11, a switch assembly 12 arranged on said frame 11, and a pusher arranged below said switch assembly 12 and installed on said frame 11 Component 13, the drainage net 10 is transported backward under the driving of the pushing component 13; and

[0065] Double-sided cladding mechanism 2, described double-sided cladding mechanism 2 includes the first composite mechanism 2a and the second composite mechanism 2b that are arranged along the pushing direction of the pushing assembly 13, and the first composite mechanism 2a and the second composite mechanism Mechanisms 2b are respectively located on both sides of the switching assembly 12 and each includes a brushing assembly 21 arranged in sequence along the pushing direction of the pushing assembly 13...

Embodiment 2

[0102] Such as Figure 15 , Figure 16 , Figure 20 , Figure 21 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0103] further, such as Figure 20 , Figure 21 As shown, the flattening assembly 242 includes:

[0104] A swing rod a2421, the upper end of the swing rod a2421 is hingedly connected with the pressure block 2411;

[0105] Swing rod b2422, the upper end of the swing rod b2422 is hingedly connected with the pressure block 2411;

[0106] A tension spring 2423, the tension spring 2423 is respectively connected to the swing lever a2421 and the swing lever b2422 and arranged in a horizontal structure; and

[0107] Pressing rollers 2424, two groups of pressing rollers 2424 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com